H.B. Carbide Grade Performs in Highly Abrasive Operations

The HB-3 grade is a submicron carbide well suited for wear parts and cutting tools being used in non-ferrous machining applications.

Share

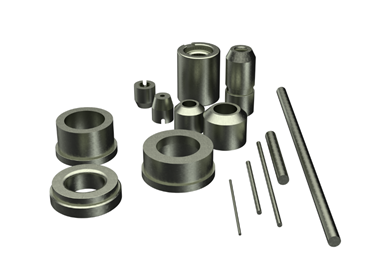

H.B. Carbide’s HB-3 grade is a submicron carbide specially designed for use in cutting tools for highly abrasive machining applications and wear components.

With a 6% cobalt binder and 93 HRA hardness, grade HB-3 is well suited for wear parts and cutting tools being used in non-ferrous machining applications. According to the company, it offers a homogenous microstructure and uniform grain distribution that makes this grade a well-suited choice for cutting tools used for machining in ISO K20 applications; specifically aluminum alloys, graphite, fiber-reinforced materials and composites. It can be applied for use in drills and reamers, form tools, end mills and other solid-carbide cutters.

The high hardness and high wear resistance of HB-3 can also perform in wear parts such as drawing tools and industrial-grade nozzles.

With a 6% cobalt content, HB-3 is said to provide consistent coating adhesion, making it a specialized substrate for toolmakers who will be applying diamond coating to their tools, especially those used for composite routing and drilling.

Jon Wyniemko, director of global sales at H.B. Carbide, says, “In addition to HB-3 carbide being an outstanding substrate selection across a variety of high-wear-resistant material applications, the consistency of the H.B. Carbide manufacturing process ensures reliable performance and prompt lead times across a variety of blank configurations.”

Related Content

-

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

-

Custom PCD Tools Extend Shop’s Tool Life Upward of Ten Times

Adopting PCD tooling has extended FT Precision’s tool life from days to months — and the test drill is still going strong.

-

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.