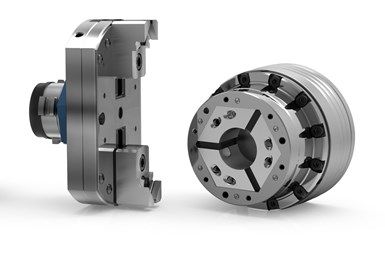

Hainbuch Two-Jaw Module Clamps Cubic Parts

Hainbuch’s modular workholding system now includes a two-jaw module that can clamp cubic parts positioned centrically on machining centers and milling machines.

Share

ECi Software Solutions, Inc.

Featured Content

View More

For users who work with a wide range of part diameters and configurations, as well as small quantities, the ideal setup is to have maximum flexibility. Hainbuch’s modular system is designed to handle round, prismatic, small and large components by allowing virtually any workholding configuration. Hainbuch’s designers and engineers in Germany are working to expand the modular system, and the company has now released a two-jaw module for clamping cubic parts.

The two-jaw module can clamp cubic parts that are positioned centrically on machining centers and milling machines. Users can change-over from clamping round parts to cubic ones in less than two minutes, according to the company. The module can also handle turning applications ranging to 1,500 rpm. Its compact profile makes it a good alternative to large, heavy centric vises.

The two- and three-jaw modules use the company’s collet chuck as their base. The Centrex quick-change interface enables users to perform change-overs without removing the collet chuck and realigning.

Because the modular system is smaller than many vises, it is less likely to interfere with machining. Applications may no longer require special, longer tools, and the risk of collision is reduced.

Related Content

-

Shop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

-

Using Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

-

Rail Manufacturer Moves Full Steam Ahead with Safe, Efficient Workholding Solution

All World Machinery Supply paired a hydraulic power unit with remote operating capabilities in a custom workholding system for Ahaus Tool & Engineering.

.jpg;maxWidth=300;quality=90)