Greenleaf Corporation Introduces New Carbide Insert Grade

The G-9610 insert grade features high resistance to built-up edge (BUE), chemical wear, abrasive wear and loss of hardness at high temperatures.

Share

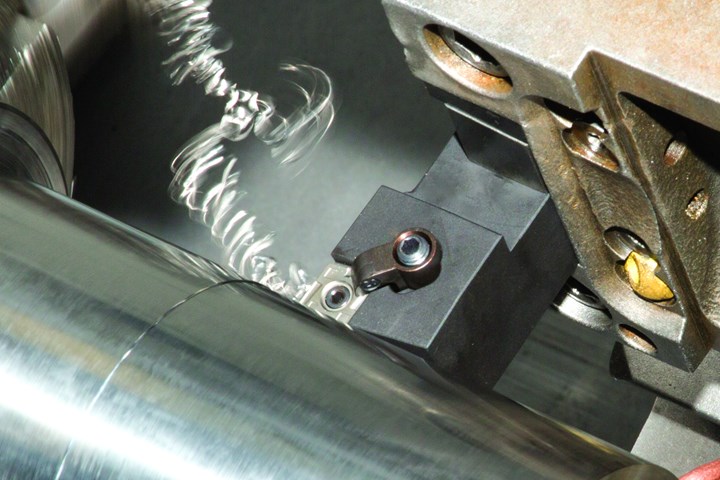

Greenleaf Corporation recently introduced carbide insert grade G-9610, a grade that reportedly delivers a 25% increase in material removal rate and up to 100% increase in tool life versus the competition when machining titanium.

The grade features a physical vapor deposition (PVD) coating combined with a proprietary sub-micron substrate, which is said to provide added productivity for turning titanium-based alloys. The coating is wear-resistant and chemically-stable, which helps to protect the heat-resistant substrate and enables higher speeds and extended tool life in continuous cuts.

Other key attributes of G-9610 include high resistance to built-up edge (BUE), chemical wear, abrasive wear and loss of hardness at high temperatures. Greenleaf says the grade is best applied at higher speeds and moderate feed rates and that it retains a sharp edge longer, relieving cutting forces and excessive heat.

“This is a breakthrough technology for machining one of the most difficult materials — titanium,” says Bernie McConnell, executive vice president for commercial at Greenleaf Corporation. “We are proud of our R&D team for again raising the bar and delivering a new titanium turning grade that offers increased value and productivity to our customers.”

Inserts in grade G-9610 are available now in various geometries and chipforms.

.jpg;maxWidth=300;quality=90)