Gear Hobbing Machines Support Job Shops and End-product Manufacturers

After a soft launch in 2020, Helios Gear Products debuts two of its manufacturing solutions from the Hera series of gear hobbing machines, the Hera 90 and Hera 350.

Share

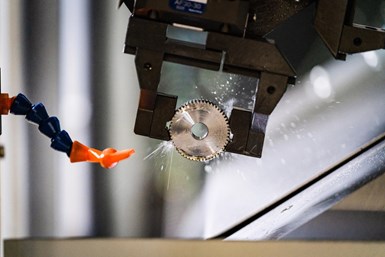

After a soft launch of the Hera series gear hobbing machines during the 2020 COVID-19 pandemic, Helios Gear Products is delighted to officially debut the leading Hera 90 and Hera 350 to the North American market. The Hera CNC gear hobbing machines support micro to coarse-pitch gear manufacturing applications with technical features such as complete FANUC CNC and direct-drive torque motors, X-axis linear scales, easy-to-use (and train) dialog programming and versatile, unified automation systems. With domestic support from the Helios team and a distinct combination of technical capabilities in a small footprint, Helios says the Hera machines offer both job shops and end-product gear manufacturers world-class hobbing solutions.

With several transformative installations across the United States, the Helios team is excited to demonstrate the capabilities of the Hera gear hobbing machines to the North American public for the first time at IMTS. Helios highlights its customer Wisconsin Gear & Machine’s experience with its products. Wisconsin Gear says its cycle times have cut down from 4 hours to a half hour, enabling for a large volume of work to be done in a timely manner with a shortage of people.

Related Content

-

Building Machines and Apprenticeships In-House: 5-Axis Live

Universal machines were the main draw of Grob’s 5-Axis Live — though the company’s apprenticeship and support proved equally impressive.

-

Inside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

-

Finding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.