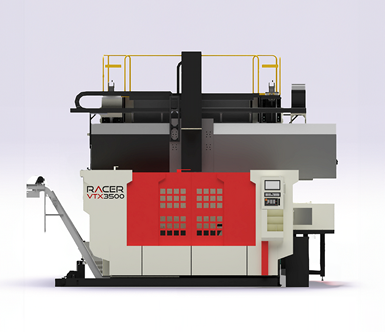

Racer Machinery Lathe Enables Full Ram Travel

The VTX machine series features programmatic indexing of the Y-axis, enabling for extended height to accommodate taller parts.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Autodesk, Inc.

Featured Content

View MoreRacer Machinery International’s VTX machine series of vertical turning lathes feature a cross rail designed for full ram travel. The rail is guided on both ends for higher accuracy and for the ability to hold two tools in each holder, enabling seamless turning of IDs and ODs. Programmatic indexing in the Y-axis enables for extended height, accommodating taller parts with ease.

The VTX series features a rail designed for full-length travel, providing turning of the internal and external diameters of a part. Supported and driven on both ends, it is said to guarantee rigidity and accuracy in machining operations. The frame, engineered using Racer’s patented Phantom Machine Design process, effectively absorbs maximum vibration, enhancing stability and surface finish.

Versatility is a key feature of the VTX series as it accepts tooling for turning, milling or grinding, offering users the flexibility to handle diverse machining tasks with precision. With a 32-station tool changer as standard, mounted off the machine frame, tool changes are quick and efficient, reducing downtime and maximizing productivity.

Related Content

-

Inverting Turning and Five-Axis Milling at Famar

Automation is only the tip of the iceberg for Famar, which also provides multitasking options for its vertical lathes and horizontal five-axis machine tools.

-

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

-

Top Shops: Designing a Shop to Meet Customer Needs

Working closely with customers and making careful investments has enabled this Wisconsin machine shop to tackle difficult jobs with tight deadlines as a core part of its business.

.png;maxWidth=150)