Filtering Chip Conveyor Supports Lights-Out Production

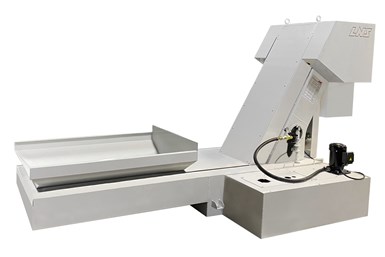

LNS’ Turbo MF4 filtering chip conveyor is designed to manage chips of all shapes, sizes and weights.

Share

Turbo MF4, the latest generation of filtering chip conveyors from LNS North America, uses a dual-conveyor system and self-cleaning filter drum to manage chip materials of all shapes, sizes and weights. LNS reports that it can handle fine, coarse, stringy and bushy mixed materials, including heavy chip loads, stringy birds’ nests and large chunks. As a result, it is suitable for unattended and lights-out production.

The filter drum features filtration to 50 µm so the machine sump remains free of contaminants, pumps are protected from damage and only clean coolant recirculates through the machining process, LNS says. It’s designed to reduce maintenance costs, extend both tooling and coolant life and improve machine uptime.

In operation, the upper conveyor transports heavy loads while the lower, scraper-type conveyor removes remaining small particles. These fines are collected in the filter drum and deposited onto the incline. Turbo MF4 has a compact design that takes up about as much floor space as most standard hinge-belt conveyors.

Related Content

-

Increasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

-

How to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

-

Using the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

.JPG;width=70;height=70;mode=crop)