Emuge Micro End Mills and Chucks Tackle High-Precision Tasks

Emuge’s Micro End Mills and Chucks improve milling performance and tool life for high-precision machining applications.

Share

Emuge Corp. has announced its new Micro End Mills and Micro Milling and Drilling Chucks for a wide range of applications including medical and die and mold.

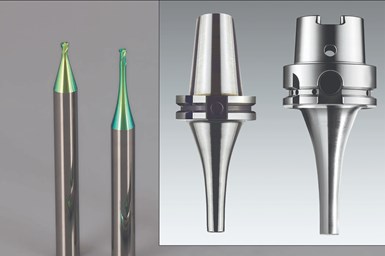

The Micro End Mills feature a patented neck design with lengths up to 10 times the diameter, enabling reach into deep contours. The new Emuge end mills offer high speed cutting finishing of 2D and 3D contours, and are offered in square, ballnose and torus end types. Featuring a short, stable cutting geometry, the end mills are available in Solid Carbide and CBN designs.

The Solid Carbide Micro End Mills are designed for high-precision machining applications up to 55 HRC, and have a heat- and wear-resistant coating. The solid carbide end mills are available with cutting diameters from 0.2 to 2 mm, and neck lengths of 2.2 times diameter, 5 times diameter and 10 times diameter.

Emuge CBN Micro End Mills offer increased tool life for high-precision machining applications up to 66 HRC. The end mills produce highly polished surface finishes without the need for rework. The CBN Micro End Mills are available with cutting diameters from 0.3 to 2 mm and neck lengths of 1.5 times diameter, 3 times diameter and 4.5 times diameter.

New Emuge Micro Milling and Drilling Chucks feature a slim design for hard-to-access areas, as well as high gripping torque and accuracy. The new micro chucks are part of the high precision and performance Emuge FPC Mill and Drill Chucks line, featuring the world's only chuck with a 1:16 worm gear. This patented design delivers three tons of traction force.

Emuge Micro Chucks are available in five shank styles (CAT, HSK, SK, BT and PSC) and hold 1-6 mm or 1/8"-1/4" shank tools. Special coated collets provide high strength and lubricity.

Related Content

-

OSG End Mills Provide High-Efficiency Milling

The company has expanded its range of end mills with two offerings for high-speed milling.

-

Tungaloy Drills, Milling Inserts Provide Enhanced Stability

Tungaloy has expanded its DrillForceMeister and TecMill lines with new drill bodies and milling inserts.

-

Walter Ceramic Inserts Enable Efficient Turning, Milling

Suitable turning and milling applications of the WIS30 ceramic grade include roughing, semi-finishing and finishing, as well as interrupted cuts.

.jpg;maxWidth=300;quality=90)