DP Technology Optimizes ESPRIT for Willemin-Macodel

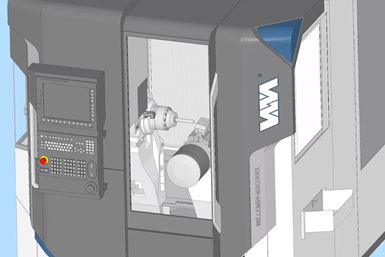

DP Technology has worked with Willemin-Macodel to optimize the ESPRIT CAM software for Willemin-Macodel’s complex mill-turn machines.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

Although the complexity and strict precision requirements for workpieces manufactured on Willemin-Macodel’s mill-turn machines made using traditional CAM software challenging, DP Technology worked directly with Willemin-Macodel to improve programming efficiency and user experience for Willemin-Macodel’s MT machines in DP Technology’s ESPRIT CAM software.

Benefits of this work include a simplified user interface for setting global machine settings, as well as capabilities for outputting machine-optimized, edit-free G-Code; creating and sorting operations in the required work coordinates; optimizing simulations to match the output NC code and actual machine behavior; displaying operation information to ease programming in ESPRIT; swift mounting of vise jaws on the turret and chucks and collets on the main and sub spindles; programming of tailstock and vise steady rest engage and disengage cycles; and flagging milling operations as cutoff operations.

DP engineers also worked closely with Willemin machine specialists to create a turn-key digital machine package consisting of post processors and virtual machines for the MT series. This package eliminates the time spent on editing the G-code and streamlines the machine setup and first article run off for end users.

DP Technology says ESPRIT provides not only a dedicated CAM solution for Willemin-Macodel machines, but also extensive engineering expertise and knowledge to make sure end users can start quickly and keep running at top efficiency using the MT series machines.

Related Content

-

Continuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

-

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

-

ERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

.jpg;maxWidth=300;quality=90)