Desktop Metal P-1 Promises SPJ Process Development Solution

Desktop Metal’s new P-1 printer provides a smaller-scale Single Pass Jetting printer that better facilitates prototyping than the full P-50.

Share

Takumi USA

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

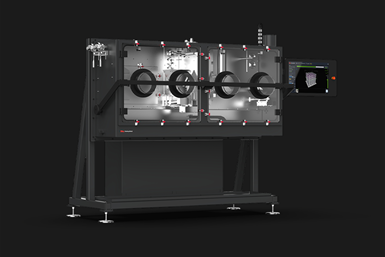

Desktop Metal has begun shipping its new P-1 printer. The P-1 leverages the same patent-pending Single Pass Jetting (SPJ) technology and core additive manufacturing benefits as the company’s flagship P-50 printer, but at the size and scale of serial production. The P-1 is now available for order and has shipped to initial customers like the Ford Motor Company.

“Adding the P-1 to our Production System portfolio serves as a key enabler for companies as they look to develop processes and materials on a smaller scale before ramping up to mass production volumes,” says Ric Fulop, CEO and co-founder of Desktop Metal. “Similarly, many businesses and research institutions are also interested in leveraging the economics and quality of SPJ technology for mid-volume serial production, making the P-1 an ideal fit and a great stepping-stone to broad adoption of Desktop Metal’s technology and flagship P-50 printer.”

The P-1 offers a new form factor that combines the P-50’s patent-pending SPJ technology and print carriage design with enhanced process flexibility. SPJ technology on the P-1 allows it to achieve production throughputs 10 times higher than those of legacy PBF systems and is fast enough to complete a full build in less than one hour. It also features a state-of-the-art print bar with native 1200 dpi, advanced printhead technology that supports a wide variety of binders and an inert processing environment that supports both non-reactive and reactive materials. Materials research and new application development conducted on the P-1 transfers directly onto the P-50 to easily scale to mass production.

P-1 customers also gain access to Desktop Metal’s Fabricate manufacturing build preparation software, as well as to the company’s newly-released Live Sinter application, which dynamically simulates the sintering process and generates print-ready geometries that compensate for the shrinkage and distortion that take place during sintering.

Related Content

-

The Cool Parts Showcase Seeks Innovative 3D Printed Parts

Do you solve problems with 3D printing? Enter your 3D printed parts in this contest from The Cool Parts Show.

-

Digital Transparency in Machining Key to Multi-Site Additive Manufacturing

Cumberland Additive’s CNC programmer in Pennsylvania spends most of his time writing programs for machine tools in Texas.

-

Go Digital: How to Succeed in the Fourth Industrial Revolution With Additive Manufacturing

The digitalization of manufacturing is set to transform production and global supply chains as we know them, and additive manufacturing has been leading the way in many industries.