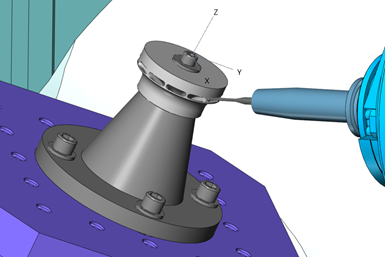

Concepts NREC's CAM Software Features New Coordinate System

The latest Max-Pac software offers two new blade finishing toolpath methods for producing five-axis machining tool paths.

Share

Concepts NREC has announced an update to its Max-Pac CAM software suite, which is specialized for turbomachinery.

The latest version of Max-Pac offers two new blade finishing toolpath methods for producing five-axis machining tool paths. First, a new method for parallel-to-hub depth, which enables more consistent pass stepover from leading edge to trailing edge for reduced cycle times, and second, a new option to cut edge paths from the center out toward the blade faces for more rigid machining.

Max-Pac v2023.1 also introduces a new coordinate system feature, which enables users to simulate multiple machining setups with a single working model configuration; transform CAD models between coordinate systems; and import and export CAD models relative to alternative coordinate systems for machine simulation.

Additionally, the Mixer tool paths have been enhanced to reduce calculation time and support more roughing methods.

Ryan Lussier, CAM software product manager says, “We work closely with our machine tool partners and daily users to get feedback on what they need to efficiently manufacture the highest quality, complicated geometries for state-of-the-art turbomachinery components. Their input drives our development team to bring improved capabilities to Max-Pac.”

Related Content

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Automated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

-

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.