CNC Software Releases 2023 Update

CNC Software LLC has released Mastercam 2023, with updates driven directly by users.

Share

CNC Software LLC, developer of Mastercam, has released Mastercam 2023. Manufacturers worldwide got the chance to test-drive Mastercam 2023 during the Public Beta Program before it was released; they provided valuable feedback to help shape the final 2023 product. The company says many of the improvements in Mastercam 2023 are directly driven by users and shops, as it has incorporated feedback from Public Beta releases, shop visits, customer surveys and consultation with expert industry partners.

One new feature is the Unified Multiaxis toolpath, which brings together Morph, Parallel, Along Curve and Project Curve strategies into a single interface, delivering expanded and flexible cutter path creation. The Unified toolpath allows access to these cut patterns when users add the appropriate curves.

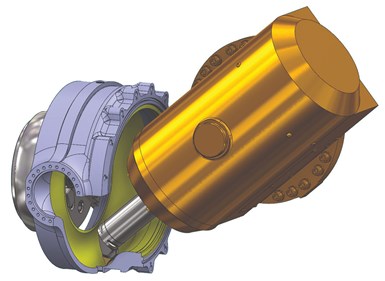

Mastercam 2023 introduces a new tool path to the Turning suite for the Mill-Turn product. B-Axis Contour Turning is a finishing tool path that allows for rotation of the B-axis while the tool is cutting. The tool path features a top-down workflow and provides users with either automatic or manual motion control. The company says automatic mode produces safe toolpath motion that keeps the insert in contact with the contour. Manual mode offers full control over the B-axis angles along the contour.

The Dynamic OptiRough and Area Roughing tool paths can now be aware of undercut stock conditions. The company says this improves the toolpath motion, including less air cutting. Mastercam 2023 also features the new Machine Group Setup function panel for mill and router machine groups. This panel encompasses features and functionality from the Machine Group properties dialog box. Machine Group Setup provides a clean, modern interface to define stock, material properties, workholding, tool, and simulation settings, according to CNC Software.

Related Content

-

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

.JPG;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)