CGTech Adds GDML Interface for Vericut

The 3DLive interface from CGTech enables Vericut software to read geometry description markup language (GDML) files.

Share

CGTech’s Vericut software can now read geometry description markup language (GDML) files with the 3DLive interface. Vericut software is designed for CNC simulation, verification, optimization and analysis and for additive manufacturing. GDML is an application independent geometry description format based on XML.

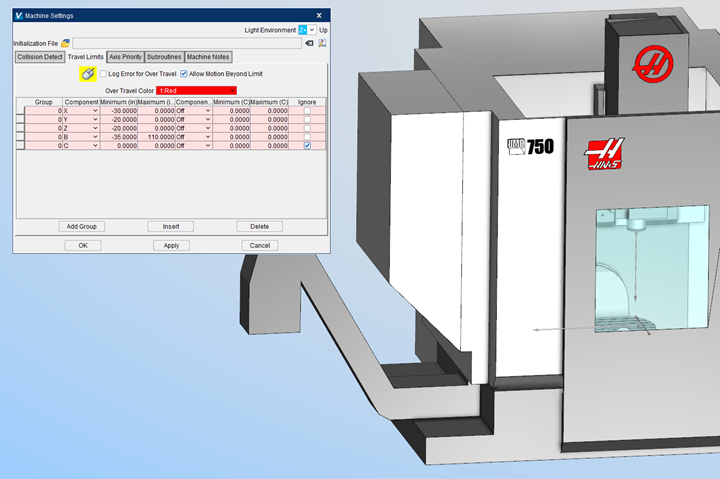

An example of the 3DLive interface with a Haas UMC-750

3DLive is available in MachiningCloud for products that require kinematics, such as machine tools and workholding devices. MachiningCloud has traditionally been known for the ability to provide 3D models of cutting tools for use in Vericut and other related CAD/CAM and simulation software. DMG MORI, Haas Automation, Mazak, Kennametal and Kurt Workholding are among the first to supply GDML machine tool, driven turret units and fixture models to MachiningCloud.

Vericut is the first software of its kind to support the import of 3DLive files for use in verifying, simulating and optimizing NC programs, according to CGTech. Vericut gives users the ability to read in 3DLive data for CNC machines, workholding fixtures and cutting tool holders for use in simulations. The company says that this eliminates the need to measure and model components by traditional means or request 3D models from the machine tool builder.

The 3DLive catalog in MachiningCloud currently contains over 8,700 products. 3DLive files contain kinematics, travel limits, minimum and maximum feed rates, initial machine location and 3D geometry colors in a single file format. This data can quickly be read into Vericut. 3DLive fixtures are designed to exactly represent the workholding setup in a Vericut simulation. These fixture models sometimes contain axis movement (such as vise models that open/close). Additionally, 3DLive tool assembly holders can be read into Vericut’s Tool Manager.

.JPG;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)