Ceramic Turning Grade Offers Alternative to PcBN

Kennametals’ KYHK15B grade reportedly provides greater depth of cut capabilities than PcBN inserts when machining hardened steel, high-temperature alloys and cast iron.

Share

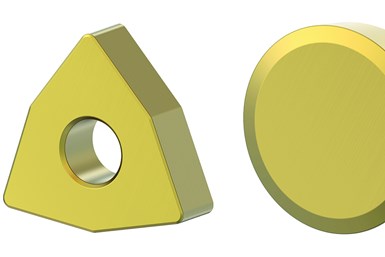

Kennametal introduces its latest ceramic turning grade, KYHK15B, designed to deliver increased productivity and lower cost per edge in hard turning operations. The new grade reportedly provides greater depth of cut capabilities than PcBN inserts when machining hardened steel, high-temperature alloys and cast iron, as well as maximum tool life and wear resistance for demanding turning applications.

According to the company, KYHK15B provides excellent edge stability, high chipping resistance and a physical vapor deposition (PVD) gold coating that makes identification of wear progression very easy. KYHK15B is designed to be an economic alternative to PcBN inserts.

KYHK15B builds on an existing line of high-performance ceramic turning grades, providing manufacturers a productive solution for hard turning applications even in varying or heavy depths of cut.

Related Content

-

Sandvik Coromant Damping Mechanism Enhances Turning Adapters

Sandvik Coromant announces upgrades to the damping mechanism for its Silent Tools turning adapters, improving surface finish during internal turning operations at long overhangs.

-

Sandvik Coromant Turning Grade Provides High-Feed Roughing

The GC4405 steel turning grade features a new carbide substrate with an optimized microstructure, which reduces plastic deformation in high-feed applications.

-

Walter Turning Grades Feature Curved Wiper Cutting Edge

The FW4 and MW4 positive wiper geometries provide a wiper action that can reportedly be used to reduce machining time by using double the feed rate.