Authentise MES Software Provides Real-Time Quoting

Flows and FlowsAM include features such as data-driven status updates, material genealogy, supplier management and more.

Share

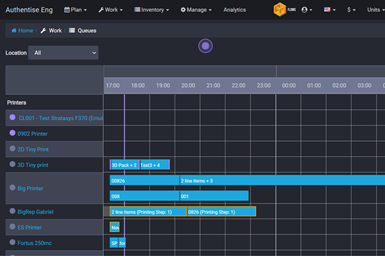

Authentise, a provider of data-driven engineering and manufacturing workflow tools, has released its rebranded workflow management suite for both additive manufacturing (AM) and non-additive applications: Flows and FlowsAM.

Flows is said to expand on traditional manufacturing execution systems (MES) to include features such as real-time quoting, data-driven status updates, material genealogy, supplier management and more. These features are used to manage post-processing such as heat treatment, machining and more. Authentise provides FlowsAM for operations primarily centered around AM, and Flows for those that are not.

“We have long sought to use our experience in the additive sector to fuel digital manufacturing as a whole,” says Andre Wegner, CEO of Authentise. “Additive has key advantages that make it a fertile sandbox, such as more data, less legacy and focus on lot size 1. That ability to manage agile operations is increasingly in demand as the world moves to address recent supply chain failures. That is why we’ve chosen this point to release Flows and FlowsAM.”

Keith Perrin, vice president of agile manufacturing at Authentise, adds, “Authentise’s ability to integrate machine data, third-party software tools and human operations into a contextual process is critical to meeting that need.”

Related Content

-

Tips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.