ANCA's CIM3D Tool Grinding Software Enables Remote Programming

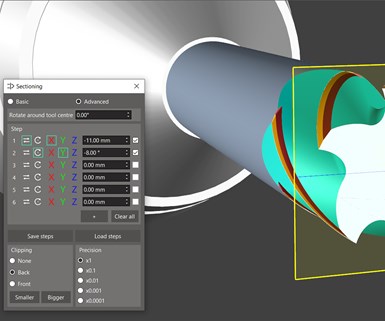

Version 9 of ANCA’s CIM3D or CIMulator3D tool grinding simulation software has an upgraded interface with fresh colors and icons for easier use.

Share

Version 9 of ANCA’s CIM3D or CIMulator3D tool grinding simulation software has an upgraded interface with fresh colors and icons for easier use. CIM3D V9 enables customization based on regularly-used features and off-line verification of background calculations, increasing machine productivity. It also enables those working from home to perform programming remotely.

The new version offers clearer visualization with a customizable timeline panel: a central dashboard speeding tool analysis. New tool programs can be verified for size, shape, machine clearance, cycle time estimates and more. Users can determine protrusion length, estimate cycle times, increment position with the mouse’s scrolling function and more.

Related Content

-

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

-

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

.jpg;maxWidth=300;quality=90)