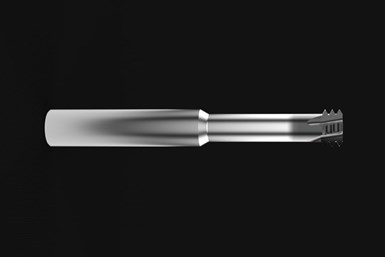

Allied Machine and Engineering Offers New Sizes of Thread Milling Tools

The AccuThread T3 thread mill line is now available in larger UN and ISO sizes up to 1"-8" and M24 × 3.0.

Share

Allied Machine and Engineering, a leading manufacturer of holemaking and finishing cutting tools for the metal-cutting industry, announces the addition of new sizes to the AccuThread T3 thread mill line. The AccuThread T3 is now available in larger UN and ISO sizes up to 1"-8" and M24 × 3.0. Machine coding for the new sizes is included in Insta-Code, Allied Machine’s online thread-mill program generator.

Targeting high-production facilities, tool and die industries and high-temperature applications, the additional AccuThread T3 thread mill sizes are said to create a high-quality thread without the concern of breaking a tool in an expensive workpiece. It is designed to only machine three threads at a time, which reduces tool pressure and increases the chances of tool survival.

Related Content

-

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

-

The Impact of Cutting Teeth Spacing on Machining Stability

Many cutter designs are available, and variable teeth spacing (or variable pitch) cutters can be used to influence milling stability. Let’s discuss why teeth spacing affects stability.

-

Toolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

.png;maxWidth=300;quality=90)