SolidCAM Conference Live Stream Will Feature Latest Updates

The annual SolidCAM World conference will be live streamed on September 5-6, 2023.

Share

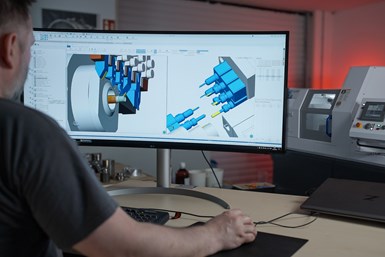

SolidCAM, a producer of CAM software, as well as technical and post-processor support for CNC machining, will be live streaming its annual SolidCAM World conference on September 5-6, 2023.

SolidCAM experts will highlight the latest module updates and enhancements, and will showcase the latest version of SolidCAM.

“SolidCAM World is an important event for our customers, prospects and resellers,” says Emil Somekh, SolidCAM’s CEO. “The live stream broadcast gives us the opportunity to show everyone around the world what SolidCAM provides to make their CNC machining businesses more profitable and more productive.”

SolidCAM is designed to provide faster, more efficient machining, seamlessly integrated and associative in Solidworks, Solid Edge and Inventor. SolidCAM’s iMachining reportedly saves 70% or more in CNC machining time, increases tool life by five times or more and provides optimal automatic feeds and speeds with the patented Technology Wizard.

SolidCAM’s multichannel mill-turn and Swiss-type CAM includes post-processors for all complex mill-turn and Swiss-type CNCs. Users can optimize their machining with SolidCAM’s multichannel synchronization and can see complete machine simulation for safer machining.

SolidCAM Additive provides the complete solution for cost-effective, combined 3D metal printing and CNC machining. With hybrid manufacturing, users can 3D print a part in metal, then CNC finish it, saving costs compared to traditional manufacturing. SolidCAM’s extensive machining knowledge helps guide the entire process from design to 3D printing to CNC machining.

Register for the SolidCAM World 2023 live stream here: www.solidcam.com/scw/mms-2023.

Related Content

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

-

Tips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

-

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

.jpg;maxWidth=300;quality=90)