Oqton Partners With Valk on Automated Robotic Welding

The companies will jointly develop new techniques and processes to enhance the utilization of automated robotic welding for unique or small-batch production.

Share

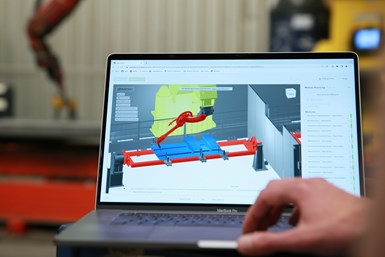

Oqton, a software provider of automation production solutions, and Valk Welding, a manufacturer of flexible arc welding robots, have announced a new partnership. Oqton’s software will become part of Valk Welding’s Automatic Robotic Programming (ARP) solution for high-mix, low-volume (HMLV) production. The Valk Welding ARP, when powered by Oqton reportedly enables ten-times faster programming than traditional offline programming solutions. Automated robotic welding is said to be three-times faster than manual welding at up to four-times lower cost than manual labor, according to the companies. The new techniques and processes the companies will jointly develop are intended to enhance the utilization of automated robotic welding for unique or small-batch production that was previously only economically viable using manual methods.

The Valk Welding ARP powered by Oqton autonomously generates robotic welding programs directly from 3D CAD files, reducing the need for costly programming. The solution relies on artificial intelligence to learn from an operator’s best practices to refine processes for future parts. As a result, welders can use this software without previous knowledge of robots or 3D geometry. This solution is ideal for HMLV robotic welding for steel fabrication sub-contractors who are manufacturing lifting platforms, transport pallets, fencing and automotive sub-frames.

Mark Forth, general manager of industrial manufacturing at Oqton comments, “Together we will help customers take their first steps towards fully automatic robot welding, using ARP powered by Oqton.”

Peter Pittomvils, CCO for Valk Welding Group, adds, “Our market lead in 100% offline programmable welding robots is ready to make the jump to the next level. Besides our own projects, we also support Oqton to all other Panasonic system integrators to also serve their customers with this great solution and our experience.”

Related Content

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

-

Four-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

-

Investing in Automation, Five-Axis to Increase Production Capacity

To meet an increase in demand, this shop invested heavily in automation solutions and five-axis machines to ramp up its production capabilities.

.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)