Henning and P1ston Agreement Offers New Add-ons for ERP Product

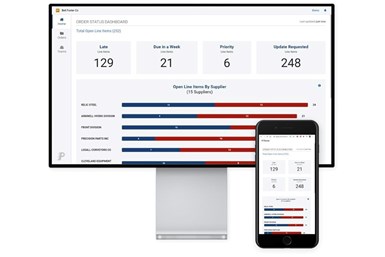

P1ston's supply chain solution is now an add-on in Henning's ERP product, Visual EstiTrack. The add-on assists with tracking orders.

Share

Henning Industrial Software Inc. and P1ston Inc. announce the agreement between the two companies to co-market and sell P1ston’s supply chain solution as an integrated add-on to Visual EstiTrack, Henning’s ERP product. The add-on is a purchase order tracking and visibility module that replaces the spreadsheet-email patchwork fix that many companies use to track open orders. The EstiTrack-P1ston hybrid cloud solution is available immediately.

An early customer, David Dussault, founder and CEO of Package One Industries, says he witnessed promising results. “We’ve successfully relied on EstiTrack for well-over a decade as we’ve tripled the size of our contract manufacturing business,” he reported before continuing, “We use the P1ston add-on to make EstiTrack even more powerful, and we’re happy to report better on-time delivery, fewer surprise shortages and lower costs.”

EstiTrack is intended to be used by small to medium-sized job shops, but it can be found being utilized in precision machining, powdered metal, glass, tool and die, fabrication, distribution, assembly and other industrial-related companies as well. It is designed to manage key internal operations and financial workflows, including estimating, sales orders, shop orders, time collection, job costing, visual scheduling, inventory management, purchasing, receiving, shipping and invoicing.

P1ston increases visibility and reduces disruptions in mission critical B2B supply chains, starting with an industrial market focus on inbound raw materials, parts and components. As a supplement to an ERP such as EstiTrack, solutions from P1ston manage workflows between customers and vendors.

Henning reports it is excited by the power of P1ston’s supply change management add-on. The complementary tool is user-friendly and improves Visual EstiTrack’s capabilities by creating a real-time conduit between the ERP system and suppliers for customers, according to the company. It is meant to streamline communications with suppliers in a frictionless way by providing them with a simple email-based tool so suppliers can update PO status, delivery dates and pricing without having to login to a customer portal.

Related Content

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

-

Continuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

.jpg;maxWidth=300;quality=90)