Esprit launches On-Demand Learning Center

Esprit has launched Esprit Learning Center, an on-demand platform for teaching prospective CAM users the Esprit CAM software.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

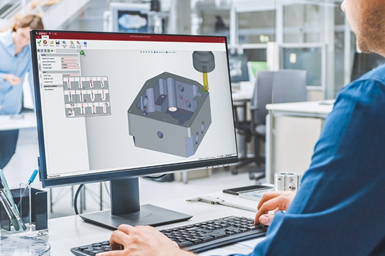

Esprit has launched its on-demand training platform, the Esprit Learning Center, to the general public.

Traditionally, Esprit applications engineers lead in-person trainings in Esprit offices and also on-site at customer facilities around the world. To support customers throughout the pandemic, however, Esprit began conducting instructor-led, online training sessions in early 2020. In this spirit, Esprit has launched the Esprit Learning Center to allow learners to access training anytime, anywhere.

The Esprit Learning Center is an online training platform with on-demand, self-paced training courses created specifically for Esprit CAM programmers. The “New User Milling” learning path is available now, with additional learning paths such as “New User Turning” and “New User Mill-Turn” soon to follow. Esprit plans for each learning path to include five to seven training courses that guide users through several different machine models and part models to introduce different machining processes in Esprit.

The main purpose for creating discrete online learning paths is to replicate what a student can learn from an on-site training class. Esprit customers can learn at their own pace while saving the time and cost associated with traveling. Each learning path also comes with one Esprit student license for each learner, so users can take the courses at home or in their free time.

“Our end goal is to make high-quality Esprit training courses more accessible to our global customers,” says Yijun Fan, director of Product Marketing at DP Technology, the makers of Esprit. “We want to share our best practices with users so they can optimize their machine programming to reduce cycle time, machine setup time and machine downtime. We want our users’ machines to start running as soon as possible and keep running at the highest efficiency. That’s always going to be our priority at DP Technology.”

Related Content

-

Building Machines and Apprenticeships In-House: 5-Axis Live

Universal machines were the main draw of Grob’s 5-Axis Live — though the company’s apprenticeship and support proved equally impressive.

-

Addressing the Manufacturing Labor Shortage Needs to Start Here

Student-run businesses focused on technical training for the trades are taking root across the U.S. Can we — should we — leverage their regional successes into a nationwide platform?

-

Finding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.