Caron Engineering, Wolfram to Open Production Tech Center

Production Technology Center to open at Wolfram’s Austin, Texas location that will showcase Caron lights-out machining solutions.

Share

Caron Engineering and Wolfram Manufacturing are collaborating to open a new production technology center in Spring 2022. The Tech Center at Wolfram’s Austin, Texas, location is designed to offer potential and existing customers a look into the results of implementing smart manufacturing systems as applied to real-world production.

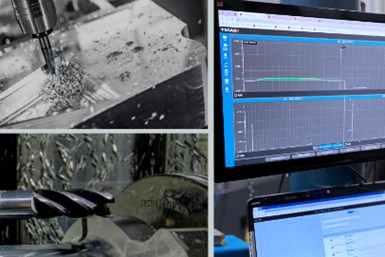

Wolfram Manufacturing, a systems integrator for Caron Engineering products since 2015, says it has focused its business model on using the best technology manufacturing has to offer and creating an environment that appeals to the next generation of the manufacturing workforce. Wolfram is a production machine shop that has integrated Caron Engineering technology to automate and optimize productivity on all its manufacturing cells. The aim of the production technology center will be to provide a centralized hub for customers to access technologies for automation, cycle time reduction, unmanned operation and total process monitoring and control for tool loading, offset adjustment and more. Mainly, the center is designed to show how implementing digital technologies can result in 24/7 production with little to no machine operator intervention or attendance.

The company lists technology center highlights that include a full production environment with thousands of hours of cutting time across CNCs, including turns, lathes, mills, EDMs, broaches and Swiss-type machines; Caron Engineering products enabling fully automated production machining; integration of Caron products with other technologies that enhance production management; training programs for the Caron product line of smart manufacturing technology; and actionable use cases to improve ROI in any production environment.

Caron Engineering and Wolfram are planning an official grand opening event in the spring of 2022.

Related Content

-

Using the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

-

Investing in Automation, Five-Axis to Increase Production Capacity

To meet an increase in demand, this shop invested heavily in automation solutions and five-axis machines to ramp up its production capabilities.

-

How to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

.JPG;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)