Bourn & Koch to Showcase Gear Hobbing Machine

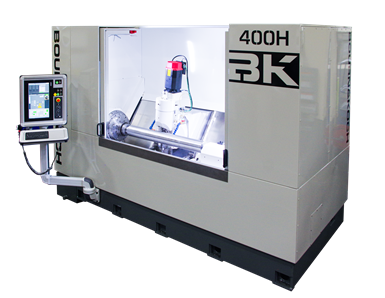

Bourn & Koch plans to showcase their flagship horizontal gear hobbing machine, the 400H, and their new Fellows 10-4 CNC remanufacture package in their booth at Motion+Power Technology Expo.

Share

Bourn & Koch Inc. will participate in the Motion+Power Technology Expo from September 14 through 16, 2021 in St. Louis.

Organized by AGMA, Bourn & Koch plans to showcase its flagship horizontal gear hobbing machine, the 400H, in its booth at the expo. Designed for producing large diameter gears in a compact footprint, the 400H reportedly allows for a highly efficient way to hob long spline shafts and gears on large shafts for a variety of industries, including aerospace, agriculture, heavy equipment and defense.

The 400H’s predecessor is the Barber-Colman 16-16, a machine still used by many gear manufacturers. The Bourn & Koch 400H provides a way to upgrade the Barber-Colman with standard single and multiple cut cycles, a Fanuc 0i-F CNC control with conversational programming, a power-programmable CNC hob swivel, automatic hob shift, along with crown and taper hobbing cycles. Additionally, the machine will feature an integrated probe arm assembly, designed to be used in carbide re-hobbing applications to measure tooth to tooth spacing and for automatically detecting profile length.

Also on display in Bourn & Koch’s booth, is their new Fellows 10-4 CNC remanufacture package. This new package provides a direct drive work-spindle and infeed axis along with numerous mechanical improvements over a typical retrofit. While Bourn & Koch has provided OEM remanufactures of Fellows 10-4 gear shapers for decades, this new package, featuring a Fanuc 35i, is meant to provide an economical CNC gear shaping machine. Loyd Koch, co-founder of Bourn & Koch, was integral in bringing this product to market with the company’s engineering team.

.jpg;maxWidth=300;quality=90)