America Makes Conducts Pilot of Virtual AM Program for Students

America Makes middle school program is designed to expose students to additive manufacturing. Full rollout expected late summer.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

America Makes - National Additive Manufacturing Innovation Institute has recently completed a pilot program designed to expose middle school students to 3D printing and future career opportunities. The virtual program reportedly allows students to earn mini-badges in additive manufacturing (AM). It was funded by the National Institute of Standards and Technology (NIST, Gaithersburg, Maryland) through the Coronavirus Aid, Relief and Economic Security (CARES) Act through the Manufacturing USA National Emergency Assistance Program.

The America Makes middle school program is designed to build the career pathways and talent pipelines necessary for the highly skilled positions within the AM industry, and aligns directly to previously developed programs that target high school students, post-secondary education students and incumbent workers. Together, these badge programs are central components of America Makes’ K-to-Grey Superhighway programming to develop career and credential pathways for learners of all ages.

The 11 micro-learning modules in the middle school program feature a series of short, interactive lessons, introducing students to the basic elements of AM.

“Exposing students to 3D printing must go well beyond the widget approach of a teacher downloading a file and giving it to the students to send to a 3D printer,” says Josh Cramer, America Makes education & workforce development director. “Students need much more depth than this to take advantage of future 3D printing career opportunities. They need instruction on additive technologies and processes that engages them to synthesize the information and certifies their understanding.

“These micro-learning modules for middle school students in today’s learning environments do just that,” continues Cramer. “They equip students with the foundational knowledge and understanding to build additive competency and experience at a younger age and provide an aligned path to continue to build on that knowledge by earning full digital additive badges that have been built through Institute-led activities. For schools interested in the program, there’s an added bonus. America Makes is so committed to this education and workforce development initiative that the Institute will be making this program available at no cost to schools and students under partnership agreements.”

America Makes developed the middle school pilot program in conjunction with Bull City Learning, MxD Learn and America Makes member Fab Lab Hub LLC, a part of the International Fab Lab Network. FabLab Hub also hosts the full additive manufacturing badges. The pilots were rolled out to member middle schools and Fab Labs that are also part of the New Collar Network, a national nonprofit that is a recognized organization in the Fab Lab Network founded at the Massachusetts Institute of Technology’s (MIT’s) Center of Bits and Atoms. Participating America Makes pilot middle schools included:

- Fab Lab Hub, in collaboration with the Santa Fe Indian School

- The Gregory School (Tucson, Arizona)

- Dayton Regional STEM School (Dayton, Ohio)

- Fab Lab Tulsa (Tulsa, Oklahoma)

- Fab Lab El Paso (El Paso, Texas)

- The 3D Printing Store, in collaboration with Aurora CO Middle School, (Denver, Colorado).

Feedback from participating schools in the pilot has reportedly been positive. Dennis Conner, director of the Fab Lab at the Gregory School, says “Teaching with these modules felt like having a co-teacher, someone who could connect with the students at their level. We were able to quickly engage with creating a 3D model while having many discussions about the changing world of 3D printing.”

America Makes anticipates the middle school program being available to school districts across the country by late summer.

For more information about America Makes, its education and workforce development initiatives or how to become a member, visit here.

Related Content

Same Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreManufacturing Madness: Colleges Vie for Machining Title (Includes Video)

The first annual SEC Machining Competition highlighted students studying for careers in machining, as well as the need to rebuild a domestic manufacturing workforce.

Read MoreCan Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

Read MoreRead Next

Making Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

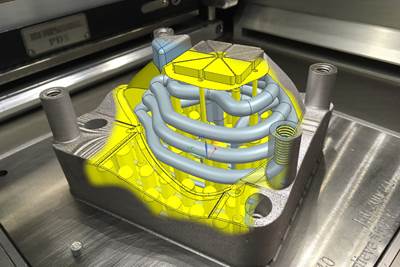

Read MoreGrowing AM's Presence in Moldmaking

Advanced Michigan mold manufacturer advocates for additive manufacturing in moldmaking through collaboration and education.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)