There are two basic principles of operation for probes used to measure surface finish—skidded and non-skidded. In skidded probes, the sensitive, diamond-tipped stylus is supported by a metal skid that rests on the workpiece, thus it uses the workpiece itself as the reference surface. Non-skidded (or skidless) probes use an internal precision rail to provide the reference for the probe. This enables skidless probes to be used with high-end surface measuring systems for measurements of waviness and form parameters, in addition to roughness. Skidless probes are indispensable for complex surface analysis, but high-end systems cost more than small, skidded gages.

Most simple roughness measurements are made using a skidded probe. Many different types of skidded probes are available. Most often, the characteristics of the part will determine which probe is the best for the application. For example, there are probes designed to measure surface finish at the bottom of a groove or along a razor’s edge. The length of the surface to be measured can also dictate the style of probe to be used.

Skidded probes can be classified into two types: longitudinal probes and lateral probes.

The skid of a longitudinal skid probe runs longitudinally (coincident) to the length of the measurement probe. The skid surface is either directly in front of or behind the measurement stylus, and it comes in contact with the surface to be measured. The length of the skid surface before or behind the probe can vary, depending on the manufacturer, but it is typically 0.120 inch. This means that the surface to be measured has to have a minimum length for the skid to operate effectively. If the skid is not supported completely during measurement, the results will be erroneous.

Probes with lateral (transverse) skids are designed so that the skid runs across the length of the measurement probe. The skid surface is directly to the left (or right) of the probe. These types of probes are often a good alternative to longitudinal-type probes because the skid length is much shorter and can be used where the measurement land areas are short, or where the area to be measured is close to a shoulder.

However, because the skid length is short, the radius of the skid surface is also small. Again, each manufacturer has its own probe design, but this type of probe typically has a skid radius of 0.012 inch. This can cause problems in certain applications.

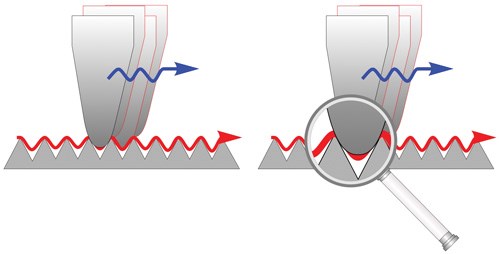

Normally, choosing one or the other of these skid-type probes is dependent on the length of the surface being measured. However, when measuring a surface with a short skid radius in the transverse direction, it may also be important to consider “peak spacing,” or “Sm,” along with the roughness (Ra) value. It is not uncommon that a very rough surface will have larger peak spacing.

This will help ensure that the short-radius skid does not “fall in between” the actual peaks. Figure 1 demonstrates an exaggerated view of a probe with a small skid radius measuring over a roughness standard with larger peak spacing. If the stylus radius falls in between the peaks, mechanical filtering of the roughness values will occur and yield measurement readings that are less than the actual values.

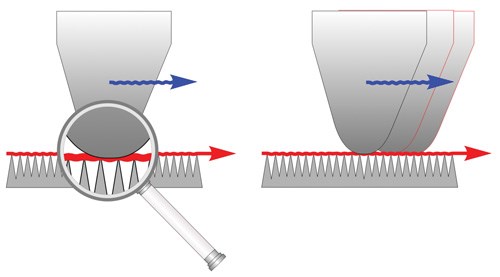

For measurement accuracy, the ideal situation is to have the skid on the measurement probe sit atop the peaks on the surface of the part as shown in Figure 2. With the skid sitting atop the peaks, the stylus will travel the full dimension from the top of the peak to the lowest valley. This will ensure that no mechanical filtering of the measurement results occurs.

.png;maxWidth=300;quality=90)