Answering, “It’s Not What We Do”

Every choice is a step toward a destination. Do you know where you want to go?

Share

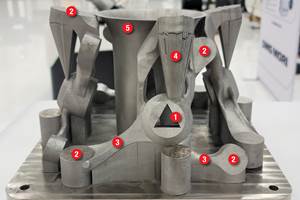

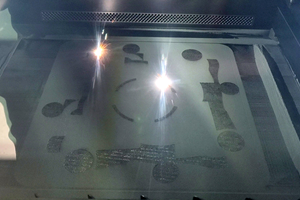

I saw a great mentor/protégé moment during my visit to Imperial Machine & Tool, subject of the March 2017 issue’s cover story. Christian Joest, part of this shop’s owning family, was concerned about a situation that would concern any manufacturing business leader: Two valuable machines—metal additive manufacturing machines—were idle. There was opportunity to put them to work. He openly wondered: Why not use the availability on these machines to serve companies wanting basic metal 3D printing work, such as prototype parts?

Chris Joest, Christian’s father and Imperial’s president, had a simple answer. He said, “It’s not what we do.” To him, the promise of additive manufacturing is not prototypes, not short-term work, but ongoing production. In fact, the promise is production of new components that can’t be made any other way. Staying focused on that promise is important, he says, even if that promise is slow to be realized, and even if it takes time and commitment to help customers develop this kind of work.

I see the younger man’s point. Imperial has been, and still is, a machining business. The old adage says your machine tool isn’t making money if it’s not making chips. Similarly, a 3D printer isn’t making money if it’s not making layers. On either type of machine, there is a good argument for taking the work you can get.

But then—and this has taken me longer—I can now see the father’s point as well. Indeed, this point applies to more than manufacturing. Whatever you have, it also has you, and whatever you do, it is doing something to you. Every step aims at a destination, so where do you want to go?

Consider this: If Imperial were to go down the road of doing one-off 3D printing work (worthwhile work, to be sure), then that would mean entering relationships with customers wanting this work. It would mean becoming connected to these companies, and making and keeping promises to them. And though there is nothing is wrong in any of this, all of it together would divert the company from seeking the work it wants. It would leave the company potentially too distracted to commit when the opportunity for that work presents itself, or even too distracted to notice when the first glimpse of that opportunity appears.

The phrase “addition by subtraction” describes something real. What we leave out enhances the effectiveness of what remains. And increasingly, I wonder if this isn’t the most powerful form of addition there is. For the organization or the individual with something of real worth to offer, there are many opportunities. There are many things to which to say yes. And saying yes produces an effect—it leads to activity, variety and the answers to pressing needs.

But Chris Joest’s point is this: The way into some kind of next-level success involves a different answer. It involves saying no. Indeed, the way forward—far forward—entails learning how and when to say no, and coming to recognize just how surprisingly often this answer is the right one.

Related Content

Designing a 3D Printed Part with Machining in Mind

Designing extra stock and mounting features into a 3D printed part can aid in machining processes downstream.

Read MoreThe Cool Parts Showcase Seeks Innovative 3D Printed Parts

Do you solve problems with 3D printing? Enter your 3D printed parts in this contest from The Cool Parts Show.

Read MoreDigital Thread Enables First-Time-Right 3D Printing

Connecting all stages of manufacturing, from design to postprocessing, helps break down barriers to industrializing additive manufacturing.

Read More6 Trends in Additive Manufacturing Technology

IMTS 2024 features a larger Additive Manufacturing Pavilion than ever before, with veteran suppliers alongside startups and newcomers at the front of the West Building. As you browse these exhibitors, as well as booths found elsewhere at the show, keep an eye out for these trends in AM.

Read MoreRead Next

Additive Manufacturing Belongs in a Machine Shop

A fourth-generation family machine shop integrates metal additive manufacturing as another production operation.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)