After the Build Is Done Why Do the Bills Keep Coming?

When your additively manufactured part is done printing, you just pull it out of the machine and start using it, right? Not even close.

Share

Autodesk, Inc.

Featured Content

View More

A metal additive manufacturing (AM) part is essentially “welded” to the build plate, and you will not be able to pull it off without some assistance. Even then, the AM part will need post processing before it is ready to use. Here are some costs associated with post processing AM parts.

Powder Removal: AM parts build “down” in a powder-bed fusion system as new layers are added to the top, which means that parts are buried in powder when they are done (see Figure 1). After the build has finished and the parts/build plate have cooled, the machine operator has to remove all of the powder from the build volume and sieve/filter/recycle it for later use, assuming you want to reuse it. This is not an expensive step, but it does take time.

Stress Relief: The heating and cooling of the metal as the part builds layer-by-layer leads to internal stresses that must be relieved before the part is removed from the build plate. Otherwise, the part may warp or even crack. Stress-relieving the part requires an oven or furnace (preferably with environmental controls) that is big enough to fit the entire build plate. Many recommend using an oven with an inert environment to minimize oxidation on the part surface. Others prefer a vacuum furnace, which costs a lot more ($100,000 vs. $10,000 to $30,000). Stress-relieving a batch of parts typically costs $500 to $600, plus shipping.

Part Removal: Most companies use wire EDM to remove parts from the build plate, however many machine shops are starting to use a bandsaw (see Figure 2) because it is faster and the bottoms of the parts must be finished anyway. Keep in mind that materials such as Inconel strain-harden as they are worked, making it difficult to remove them from the build plate with just a bandsaw. Using a local machine shop, we spend about $200 to $300 per plate for wire EDM, which can take a few hours depending on the number and size of the parts. A bandsaw can complete the task in minutes.

Heat Treatment: Heat treatment (aging, solution annealing and so on) improves the microstructure and mechanical properties of the parts and is necessary for nearly all AM parts. In many cases, this step also requires an environmentally controlled furnace with the ability to regulate the temperature and cool-down schedule. Heat treatment may affect the dimensions of the parts, so most people prefer to heat-treat parts before they machine/finish them. The American Society for Testing and Materials (ASTM) just released a standard for thermal post processing of metal AM parts. Heat treatment can easily cost $500 to $2,000 depending the material and how many parts are being treated.

Hot Isostatic Pressing: Instead of heat treatment, many aerospace companies are starting to use hot isostatic pressing (HIP), which is frequently used in the casting industry to improve the fatigue life of cast parts. A HIP system costs substantially more than a furnace/oven and comes with its own safety measures due to the high pressures (100 megapascals or more) at which it operates. Like heat treatment, HIP costs $500 to $2,000, but you often do not need to heat treat the part if you HIP it.

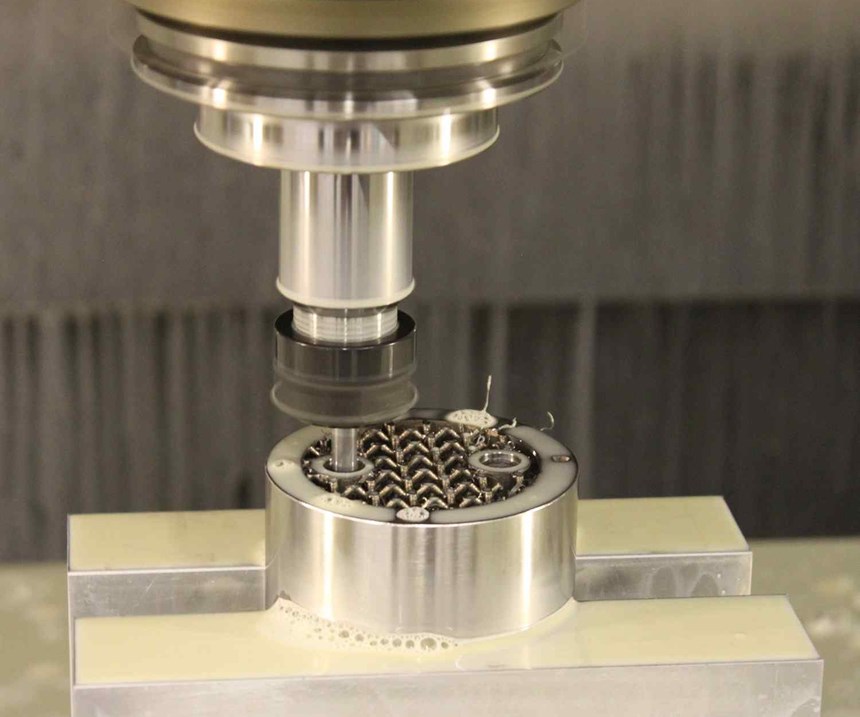

Machining: Machining of mating interfaces, surfaces, threads, support structures and more likely will be required to ensure dimensional accuracy of the finished part (see Figure 3). Few AM parts meet specifications “as built,” and if nothing else, the surface of the part that was connected to the build plate will need to be finished. Most manufacturing companies already have machining systems on hand, but registering parts and establishing datums for machining can be tricky, especially for complex, organically shaped parts made with AM. Accessing internal channels or cooling passages that need to be machined can also increase costs. The cost here is highly dependent on the material and the job as well as the fixturing needed to hold the part.

Surface Treatments: Surface finishing also might be required to improve surface finish/quality, reduce surface roughness, clean internal channels or remove partially melted particles on a part. When outsourced, these costs can easily run in the hundreds if not thousands of dollars.

Inspection and Testing: Metrology, inspection and non-destructive testing using white/blue-light scanning, dye-penetrant testing, ultrasonic testing, computed tomography (CT) scanning and more will be needed after post processing and possibly at multiple points during post processing. Destructive testing of sample parts and analysis of witness coupons (for example, tensile bars), powder chemistry, material microstructure and more also may be needed to gather data to help with process qualification and ultimately part certification. Most companies will have a range of metrology and non-destructive testing methods on hand, but AM parts with internal channels, lattice structures and other internal enhancements may require CT scanning to ensure clear passageways, evaluation of internal geometries and more. A CT scanner will easily cost $1 million to buy, install and operate.

Related Content

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreRethink Quality Control to Increase Productivity, Decrease Scrap

Verifying parts is essential to documenting quality, and there are a few best practices that can make the quality control process more efficient.

Read MoreWhat are Harmonics in Milling?

Milling-force harmonics always exist. Understanding the source of milling harmonics and their relationship to vibration can help improve parameter selection.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=150)