Understanding Electropolishing

Compared to other options for deburring high volumes of metal parts, this process is said to be particularly well suited for the smallest imperfections and most fragile workpieces.

Share

After a certain threshold, deburring gets easier. That is, when part sizes are small enough and volumes are high enough, lots of hundreds or even thousands can be cleaned up at once, whether by tumbling against one another, a different media or both.

However, volume isn’t the only factor to consider when choosing a high-volume, metal-part deburring process. The smaller the burrs and the more delicate the part, the greater the advantages of removing these raised, sharp protrusions via non-mechanical means. Specifically, via electric charges that are naturally drawn to the high points on a surface, similarly to lighting striking a tall tree.

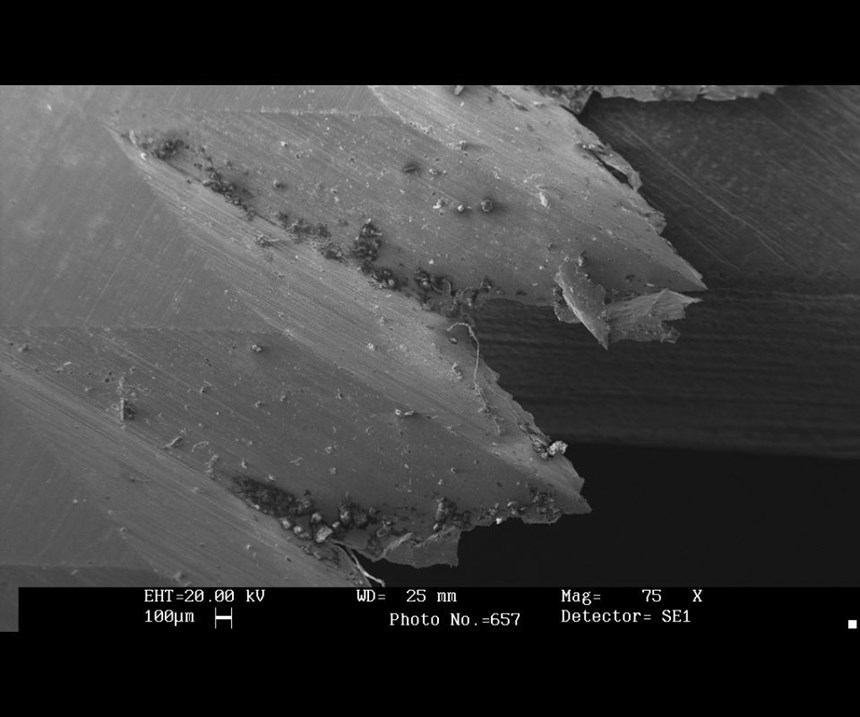

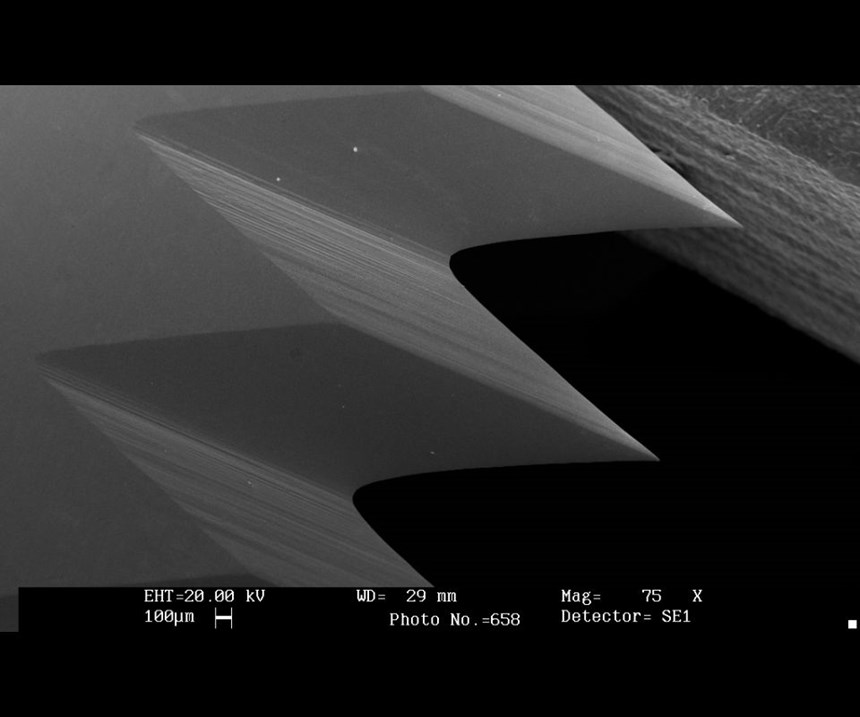

This process is known as electropolishing, and the “lightning strike” occurs not in the open air, but in a chemical bath. A rack full of workpieces, positively charged to serve as the anode, is submerged in this electrolyte solution along with negatively charged cathodes. Drawn toward the cathodes via the process of electrolysis, minute fragments of material pull away from the workpieces and into the electrolyte, leaving a behind clean, smooth surface. Afterward, multiple rinsing steps remove any residual electrolyte before the parts are dried. With highly repeatable material removal controlled to within ±0.0002 inch, parts as thin as 0.004 inch can be deburred without the risk of nicks or other imperfections that could result from even the slightest physical contact.

Although the non-mechanical nature of electropolishing makes it well-suited for the most delicate high-volume deburring applications, it is also largely limited to those applications. The longer the electrical current is applied, the greater the amount of material removed, but the less uniform the results. Thus, the process is generally suitable only for micro burrs, or those that protrude less than about 0.0015 from the part surface.

Parts with larger, macro burrs are better candidates for processes like barrel tumbling and vibratory finishing. Unlike electropolishing, these processes leverage mechanical means to smooth surfaces and round sharp edges. In barrel tumbling, the material-removal mechanism consists largely of the workpieces themselves, which are placed in a spinning container along with an abrasive compound, which is carried in a medium that also helps cushion the parts. As a side benefit, the repeated impact associated with this process can strengthen some alloys. In vibratory finishing, the removal medium consists of specially shaped pellets that are placed with the parts in a bowl or tub that vibrates at high frequency. Compared to tumbling, this process tends to be both faster and gentler on the parts. It also offers the opportunity to deburr internal part features.

However, both of these processes can leave behind material protrusions and surface imperfections. In applications with stringent surface-finish requirements, electropolishing can thus become a complement to these generally more efficient processes as a secondary finishing step. Determining the correct finishing process or series of finishing processes often requires experimenting with samples and smaller prototype lots prior to ramping into full production.

Should electropolishing be a part of your finishing equation? Here are a few key points to consider:

It targets more than just burrs.

The amount of material to be removed—as expressed by size tolerances—is the primary consideration in determining whether a part is a good candidate for electropolishing. After all, as a true finishing process, electropolishing removes material evenly from all facets of a part. Although this facilitates surface finishes on the order of 4 to 32 Ra, it also means that somewhere between 0.0005 and 0.001 inch of material must be removed for the process to be effective. Given that burrs tend to narrow as they protrude further from the surface, the width of the burr base is a more important consideration than height.

It requires more than just technology.

Although resources are available for anyone to learn the basics of electropolishing, the process is often outsourced rather than conducted in house. A major reason for this is that producing the desired results is, in many ways, an art as well as a science. Jobs differ in terms of materials, surface-finish specifications and other requirements. Processing parameters and the precise blend of electrolytes required differ accordingly.

Workholding can be complex.

Parameters and electrolyte formulations are not the only aspects of this process that require significant expertise. Even a non-mechanical process requires some means of holding parts in place. That is because parts must uniformly carry current. As a result, the parts cannot just be “hung on a hook” like they could be for electroplating, a process that uses electric current to add, rather than remove, metal but is nonetheless compared frequently to electropolishing. Customized racking dedicated to fragile parts can be both challenging and time-consuming to configure.

It works for more than just stainless.

Along with the necessary expertise for all of the above, some electropolishing service providers can process a wider variety of materials than many prospective customers believe. In addition to stainless steels, the process is suitable for brass, copper, carbon steels, nickel alloys, titanium, Nitinol and more—nearly any alloy, in fact.

Based on an article by:

Tom Able, President, Able Electropolishing

Related Content

Custom PCD Tools Extend Shop’s Tool Life Upward of Ten Times

Adopting PCD tooling has extended FT Precision’s tool life from days to months — and the test drill is still going strong.

Read MoreSelecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

Read MoreFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More