Share

Autodesk, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View MoreAs far as I’m concerned, it’s a win-win.

The machine shops that participate in our Top Shops benchmarking survey come away with a free, custom report ranking their responses to quantitative questions against those of other participants. This gives shops a sense as to where they are succeeding in specific areas of their business and where they may want to target improvement efforts. Conversely, the survey enables the Modern Machine Shop staff to better identify the technologies and strategies—applied both on the shop floor and in the front office—that leading U.S. machine shops are adopting.

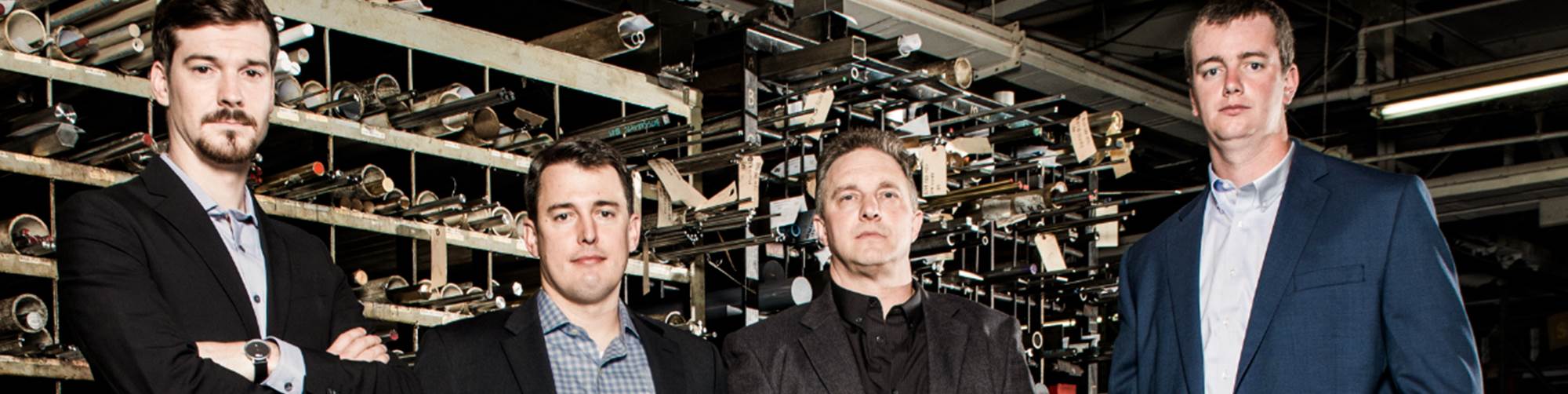

The latter provided the fodder for this article, which highlights some of the tactics from which the four winning shops of the 2018 Honors Program are benefiting. These shops are part of the 90 that comprise the top-20-percent benchmarking group established in our annual survey. They were identified by me as being particularly notable in one of the following four main survey sections: machining technology, shopfloor practices, business strategies and human resources.

In fact, we recently invited representatives from those four shops to visit our Cincinnati, Ohio. offices for this month’s cover photo shoot as well as chat with them about their operations and their use of the benchmarking reports. While all the shops in the benchmarking group excel in many aspects of their machining business, here we’re concentrating on the processes and practices the Honors Program winners are applying with respect to their award categories.

Investing Somewhat on the Edge

The winner in this year’s machining technology category is Baker Industries, located in Macomb, Michigan. When brothers Scott and Kevin Baker co-founded the company as Baker Duplicating in 1992, it was a three-person operation with 2,100 square feet of space. Today, Baker Industries has 285 employees across four facilities and 220,000 square feet of space. The tooling supplier also is now heavily focused on the automotive, aerospace and defense industries, having capabilities that include design, engineering, fabrication, welding, machining, assembly, CNC machining, 3D printing, inspection and validation.

Twenty-five-year industry veteran Jerry Kablak is the company’s program engineer and additive manufacturing champion. He says that from the beginning, the shop has focused on integrating new machining technology and was an early adopter of five-axis machining. It now has 35 CNC machines of varying types and sizes. “The approach here is to stay on the leading edge of new machining and manufacturing technologies,” Mr. Kablak explains. “Although there is risk involved, we want to add advanced processes even if the market doesn’t currently call for them or isn’t necessarily ready for them yet. Staying attuned to our customers’ needs helps shape our decisions as to what new technologies to bring in.”

One prime example is its exceedingly large five-axis Emco Mecof PowerMill, which was brought online late last year. Baker Industries says this gantry-type machine is the first of its kind to be installed in the United States and is one of the biggest and most versatile in the Midwest. Its addition is part of a planned approach to expanding the company’s capacity in servicing original equipment manufacturer (OEM) and Tier-One customers’ largest machining projects, such as assembly and bond tools. The machine with several automatically changeable heads has a 52-by-20-by-10-foot work envelope and table load capacity of 2.6 million pounds. While it obviously has the capacity to accommodate very large parts, the shop can also set up multiple jobs on its table at once or machine a part on one end of the table while setting up another job on the other end to maximize spindle uptime.

“We researched this type of machine for a few years, but nobody ever came to us promising work if we bought it,” Mr. Kablak says. “Fortunately, our company is positioned to accommodate these sorts of risks, given that we have a solid base of more straightforward work. This enables us to reach a bit without putting the business in a bad situation.”

Another example is Baker Industries’ investment in 3D-printing/additive manufacturing equipment, which the company started to add just before Mr. Kablak was brought onboard. In fact, it was at that point that he took the lead in identifying how the shop might best take advantage of this technology. Baker Industries currently has seven such machines, five being Stratasys fused deposition modeling (FDM) machines for printing plastics and two being EOS direct metal laser sintering (DMLS) models.

Where the company is realizing real value in additive technology is with hybrid tooling. That is, tooling in which some components are machined and others are 3D printed. In some cases, this enables the tooling to incorporate complex shapes or internal geometries that would be difficult or impossible to create via traditional methods. In others, it can reduce overall tooling weight.

“Part of the challenge when adopting new technology is training our team,” Mr. Kablak says. “However, it can be more challenging educating our customers to the point where they appreciate the value that advanced, perhaps atypical manufacturing processes can provide compared to traditional methods. Ultimately, our investment in new technologies serves as a sales and marketing tool, too, demonstrating the commitment we have to most effectively serving our customers over the long haul.”

Establishing Production Schedule Certainty

There are numerous initiatives recently made by Boulder, Colorado’s Hirsh Precision Products that make the 39-year-old contract shop, started by Steve Hirsh, deserving of being named this year’s shopfloor practices winner. For example, the shop, with machining capabilities that include three-, four- and five-axis milling, four-axis turning, multi-spindle turning and Swiss-type turning, earned its ISO 9001:2015 certification last year. “We’ve always focused on quality and felt like this certification was within reach for many years,” company COO Peter Doyle says. “However, we finally reached a point in which we felt that a bigger portion of our growing customer base was requiring their suppliers to be ISO-certified. Rather than continuing to pursue exemption processes to become their vendor, we put a plan in place to earn the certification.”

In 2016, Hirsh Precision Products also purchased an Okuma MU 4000V five-axis machine with a Fastems flexible manufacturing system (FMS). It has since added a second identical machine to this system. Mr. Doyle says given the shop’s high-mix/low-volume production environment, reducing setup times while maximizing spindle uptime is critical. “The 36-pallet FMS was an obvious choice for us to increase unattended production time, but it has also helped us to reduce scrap rates, lead times and finished-goods inventory,” he says. “In addition, the system’s software has an algorithm that makes real-time decisions to determine which of the two machines has the tools, raw material, spindle availability and part program available to run a particular job.” The shop plans to soon add a third machine to its FMS.

Equally impactful is the shop’s efforts to improve scheduling with its proprietary shopfloor management software called “Paperless,” which standardizes processes and provides information about job set up, inspection and production. Paperless enables managers to view data company-wide or by cell or machine. “This software is fully integrated with our ERP system and tracks programs, fixtures and cycle times for jobs and helps us control and manage revision changes,” Mr. Doyle explains. “It also enables any employee to submit ideas that may improve process efficiency.”

Hirsh Precision Products also created and implemented an electronic production “Scorecard” system last year. Scorecards are available in every production cell and show all operations, minute by minute, that are expected to be completed on a given day. The next morning, shopfloor leaders receive a report to see if what was planned was produced. This report helps determine how close the shop came to attaining 100-percent production schedule adherence (PSA). Reviewing PSA has helped the shop identify improvement opportunities.

“Our Scorecards better enable us to trace our actions to our on-time delivery rate during the day,” Mr. Doyle says. “At any moment, team members can review them to see if a particular production area is meeting its customer commitments. Our PSA and machine utilization metrics are leading indicators of our on-time delivery rate.”

Managers can also use Scorecards to identify if an employee is struggling to keep up with production demands or is encountering issues with a set up, for example. Culturally, Hirsh Precision Products uses this information to identify opportunities for training and teamwork rather than cast doubt on an employee. The Scorecards have also helped employees understand more specifically how the work they do directly relates to the company’s goals and customer service.

Because the Scorecards were implemented just last year, the shop’s leadership team meets every week to discuss how to improve upon it. In addition to sharing accountability for its success, this iterative continuous improvement approach has helped embed the Scorecards into daily operations.

Cutting Costs for Customers

After a couple stints in high school working for his grandfather’s job shop Ripley Machine, Andy Reinwald joined the company full time as shop foreman in April 2012 and eventually took over the business in January 2015 at the age of 21 when his grandfather, Quentin Bensink, retired.

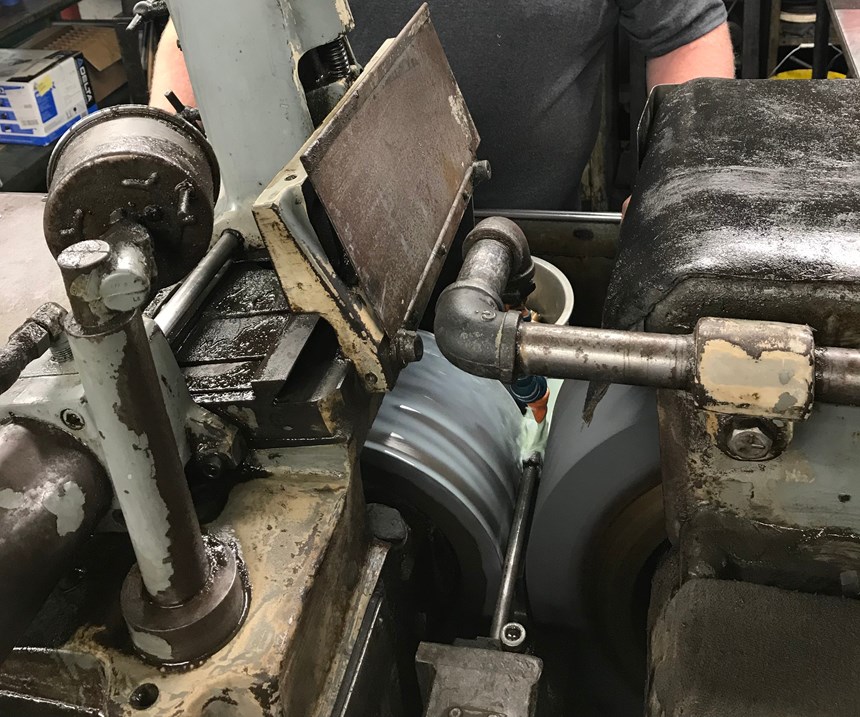

The Ripley, New York, shop provides precision grinding, CNC turning and CNC milling of aluminum, alloyed steels and nonferrous metals in low to high quantities for a wide range of industries and applications. In fact, its centerless grinding capability is beneficial from a business perspective because there are several nearby shops that do not have that capability and look for shops like Ripley Machine to provide those grinding services.

Mr. Reinwald says he and his grandfather set up the transition to be gradual, with his grandfather continuing to be part of the shop’s daily operations, offering advice and support when needed. “Having him as a mentor with no clear timetable for his retirement date was helpful,” he explains. “It was nice to be able to bounce ideas off of him as I was getting established in my new role.” Mr. Bensink permanently retired in 2017.

For the first six months after Mr. Reinwald assumed ownership of the company, everything went well. “Then, it was like the faucet was shut off business-wise and we realized the worse 18 months in company history,” he explains. “It was clear that our customers had an increasing focus on cutting costs, so we had to make it an initiative of ours to come up with creative ways to reduce our manufacturing costs as well as to diversify our customer base. This we have since done, which has led to a significant increase in sales.”

In addition to earning ISO 9001:2008 certification in 2016, one of Mr. Reinwald’s goals was to add new customers with work that was in the shop’s capability sweet spot. That is, turning work ranging in diameter from 1.5 to 6 inches in quantities not to the point in which automation may be warranted, but not less than 100-piece-batch sizes. In doing so, he has also worked to establish a good quote-to-book ratio. “I don’t like to quote a job if it seems like it will be a hassle,” Mr. Reinwald says. “I’ll immediately quote it if it seems like a slam-dunk, and I won’t if it’s obviously not in our wheelhouse. Other jobs I might discuss with my shop foreman. If that discussion lasts longer than 30 minutes, I likely won’t quote it.”

To speed cycle times to reduce overall costs and shop hourly rate, Ripley Machine has started using more capable cutting tools. It is also sourcing material from multiple suppliers to get the best price, whereas before the shop used one primary supplier. The shop sometimes buys extra material to get the per-piece price down if it feels it will be able to use the material at some point.

Ripley Machine is also more open to suggestions from those on the shop floor. Being that much of the work there repeats, there is value in taking time to find ways to more efficiently run a job. “If someone suggests that tweaking a part program can reduce the cycle time, I typically won’t have a problem with them taking 30 minutes to do that,” Mr. Reinwald says. “We’ll recoup that cost and time by having established a better process when the job returns.

“I’d like our company to continue to grow, and that might require adding new capabilities,” Mr. Reinwald continues. “For example, while we currently offer large-diameter turning and centerless grinding capabilities, we might consider adding CNC Swiss-type lathes. We currently perform centerless grinding of small-diameter barstock for some Swiss-type shops, so we would not want it to seem as if we’re competing with them. However, there might be opportunities for us to win new work if we have larger-capacity Swiss-types.”

Employee Investment Pays Off

Kylan Hastreiter, vice president—marketing and development of Hastreiter Industries, says people represent the core of this Marshfield, Wisconsin, job shop and are the key reason for its growth. The initiatives Hastreiter Industries has made to invest in its employees as well as its community is the reason why the shop is this year’s winner in the human resources category.

Formerly known as UTM Inc., Hastreiter Industries was founded in 1988 by Ken and Sondra Hastreiter with a single, manual lathe. The company had remained primarily a turning shop, having three CNC turning centers and only one supporting three-axis mill. “However, we realized that to grow, we needed to have production milling capability, too,” Kylan Hastreiter says. “In 2016, the same year that my brother Keegan and I joined our parent’s company, the shop purchased a five-axis machine with an eye toward re-entering the aerospace market, one we hadn’t been serving for more than 20 years. Ultimately, the capability to do complex contouring work as well as positioning in five axes to minimize setups with now two such machines enabled us to win aerospace as well as defense work.”

At that time, there was only one other employee besides the four Hastreiters. Today, the shop employs 11, including the owners. In fact, Mr. Hastreiter says they are continually approached by those in the area who want to work for the company.

One reason is the unique way the shop helps ensure its employees will be financially stable after retiring. On top of whatever hourly wage an employee receives, Hastreiter Industries adds 25 percent of that to the employee’s retirement account. Therefore, an employee who stays with the company through retirement will end up with a nice nest egg from which to live.

“Only 13 percent of people save the recommended 20 percent of income for retirement,” Mr. Hastreiter explains. “We don’t want a situation in which only a small fraction of our workforce is truly prepared for retirement. We want to set them up for the long term.”

For example, if at age 20 a person starts at $15 per hour and retires at age 61 making $26.50 per hour, he or she would have a retirement account valued at approximately $2.78 million thanks to compounding of the $460,000 contribution (assuming a historical average annual stock market growth of 8 percent). This also helps minimize employee turnover because it is rare for a company to offer such a benefit. Not surprisingly, the shop has had zero turnover for the last 17 years.

Hastreiter Industries is also good to the community. It donates 50 percent of its net profits, and the owners have also established a nonprofit organization called Shiloh Bound. The vision of this organization is to mentor and empower individuals from challenged backgrounds, those with limited opportunities or those who simply need direction or help in life.

“There are helpful institutions that provide mentoring for those who need it,” Mr. Hastreiter explains. “But what happens when those people leave an institution having no marketable skills or education? In some cases, they might end up back in their original, bleak environment. With Shiloh, we hope to help them continue the right path by using our business to provide them with a trade skill, so they can stand on their own personally and economically. We feel this is how you change the industry and the community.”

In fact, this is what spurred the decision to grow the business. “Our goal is to eventually train individuals, in partnership with Shiloh, and send them out into the workplace to strengthen both communities and our industry,” Mr. Hastreiter says. “Before we can do that, we have to build the business to the point that it has sufficient equipment and staffing available to offer that training. Ultimately, Shiloh will provide the mentoring for life and soft skills while Hastreiter Industries will be there to provide a trade skill.”

Related Content

2024 Top Shops Honorees Announced

Modern Machine Shop Recognizes Excellence in Manufacturing with Annual Award

Read MoreFinding Skilled Labor Through Partnerships and Benefits

To combat the skilled labor shortage, this Top Shops honoree turned to partnerships and unique benefits to attract talented workers.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read MoreTop Shops 2024 Is Now Live

The Top Shops 2024 survey for the metalworking market is now live, alongside a new homepage collecting the stories of past Honorees.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)