The Little Shop That Could (with the Help of a Tapping Arm)

A pneumatic tapping arm enabled a small job shop to complete a challenging job in a week that would have taken other shops months to finish.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

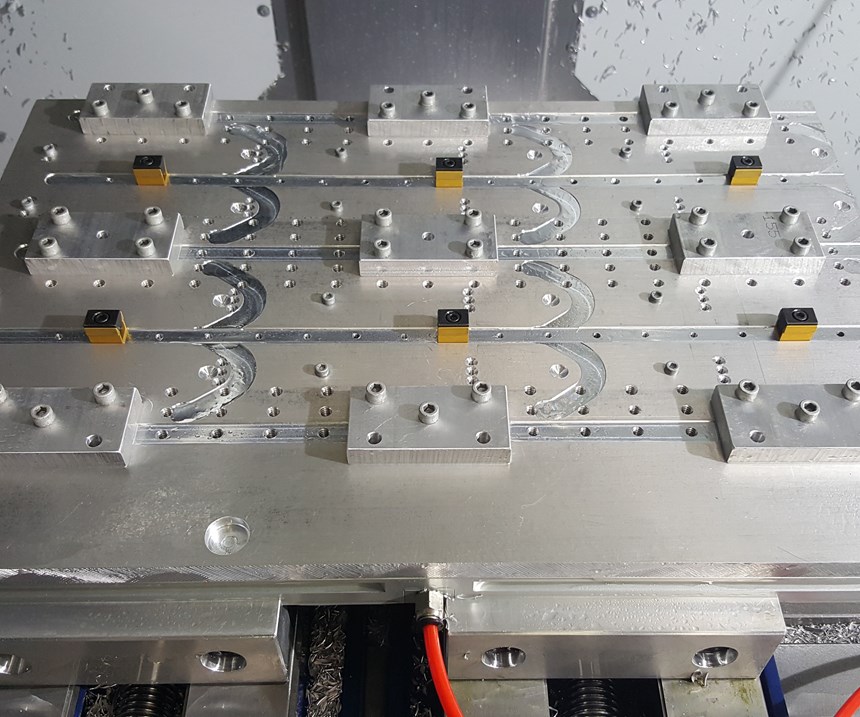

View MoreSometimes shops are asked to take on jobs that seem impossible. Little Enterprises, a small shop in Purcellville, Virginia, was faced with such a task last December. A new customer had a job consisting of six plates that each required 600 holes to be tapped. The real challenge, however, was the timeline: The job needed to be completed in a week. Three other shops had told the customer that it would take months, but Little Enterprises was able to tap all 3,600 holes in the allotted timeframe with the help of a tapping arm from FlexArm (Wapakoneta, Ohio).

A Little Shop with a Big Job

Little Enterprises gets its name from its founder, Rob Little, but it also describes the number of employees. The shop consists of Mr. Little and his father. His wife is also on the payroll, and his 12-year-old daughter and 13-year-old son help after school, on weekends and during Christmas and summer breaks.

What the shop lacks in operator quantity it makes up for in technology. Mr. Little uses Autodesk Inventor, a parametric 3D solid modeling software, to speed the prototyping process. For instance, when he makes changes to the design of the model, the CAM software updates the code for the shop’s CNC lathe mill.

That said, that plate-machining job presented a challenge. The shop’s CNC mill did not have adequate Z-axis travel to handle the thickness of the plates or the ability to tap holes all the way around the parts, so using it to perform the tapping operations was not an option. He also did not want to risk breaking a tap in one of the holes or cross-threading the ¼-inch-thick, 14-inch-tall 6061-T6 aluminum plates, which cost $1,000 each. Because of the difficulty of the job and the tight turnaround, Mr. Little had little time to consider solutions.

The Tapping Arm’s Advantages Over a CNC Milling Machine

Mr. Little remembered seeing a video on Facebook of a pneumatic tapping arm from FlexArm, a manufacturer of drilling and tapping solutions. He put a call into the company and ordered an A32 model.

FlexArm’s pneumatic arms are specifically designed for fast and easy tapping. With adjustable gas counter-balanced springs, operators can simply position the tap over a hole and execute the tap. The FlexArm can also be adjusted to stay where it is positioned or automatically return to the home (folded) position. The tap head is always at 90 degrees to ensure accurate threading with the Helicoil inserts.

The FlexArm counterbalances the weight of the motor and absorbs the torque created by the tool to reduce fatigue and the risk of operator injury. A quick-change chuck enables operators to quickly change tap sizes without changing gears, head height or stops.

When the FlexArm arrived, Mr. Little wasted no time. He set up the parts in Kurt vises and had his 13-year-old son do the tapping while he filmed it to make his own Facebook video. “The FlexArm is not considered hazardous manufacturing equipment under Fair Labor Standards Act (FLSA) definitions, and my son loves using it,” he says.

Now that Little Enterprises has a tapping arm, it does not need to program tapping into its CNC machine. Even with its rigid tapping capabilities, the time required to program the machine, put a tap in, touch it off and switch parts was too great. The process of tapping on a milling machine also requires the spindle to slow down, come to a complete stop at depth and reverse back out of the holes, in addition to the time needed to change tool heads and reposition the part. On parts with multiple holes, each additional hole slows down production. With the FlexArm, Mr. Little drills the holes on the CNC, takes the part out and replaces it with a new part for drilling. While the new part is in the machine, the drilled part receives tapping. Tapping offline moves each part through the process more quickly and makes the most of operator time.

Savings and Benefits

The seconds saved on each hole can add up to substantial savings for the customer. Rates for Little’s machine time generally run between $80 and $100 per hour. If a part has 12 holes and each takes 10 seconds, that is 2 minutes per part which leads to 30 parts per hour. At a cheaper rate of $60 per hour, he can charge $2 per part, reducing prices while increasing the number of parts produced per hour.

The FlexArm has also helped Little Enterprises reduce tooling costs. The tapping arm’s adjustable torque clutch enables the tap to stop turning when it encounters any obstruction that might cause breakage. Mr. Little likens it to a manual drill press that the operator can feel as it drills. With the FlexArm, the operator has control, which is an important factor when machining tiny screws and holes.

A CNC machine might break a tap every 300 holes, whereas a FlexArm averages 1 broken tap every 3,000 holes, the company says. When using the FlexArm, the operator can catch a chipped tap before it breaks, while a CNC machine keeps going and breaks the tap. Breaking a tap can ruin an expensive part or stop production while an operator digs out a tap fragment.

By speeding production, freeing up time on the shop’s milling machine and reducing tooling costs, the FlexArm paid for itself on its first job.

Related Content

DN Solutions America Unveils Impressive Chicago Technical Center at IMTS 2024

New tech center is serving as a cutting-edge showroom and a technological hub for advanced machining applications.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreDN Solutions' VMC Provides Diverse Five-Axis Machining

The company’s DVF Series comprises compact five-axis CNC machines that are designed for diverse five-sided or simultaneous five-axis applications.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)