Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

A. Vinod, CEO of Up LLC, the company developing the new “Up!” app for machine tool maintenance, says his company’s research shows that 1.5 percent of machine tools are out of use due to some form of unplanned downtime at any given moment. The unplanned downtime frequently prompts the need for unplanned maintenance attention, and shops tend to rely on their machine suppliers for this maintenance. However, 1.5 percent is a large portion for machine tool builders and distributors to try to service promptly. During an economic period such as this when manufacturing is busy, shops know the result of this demand: There is queuing of service requests, with some shops left waiting for service appointments.

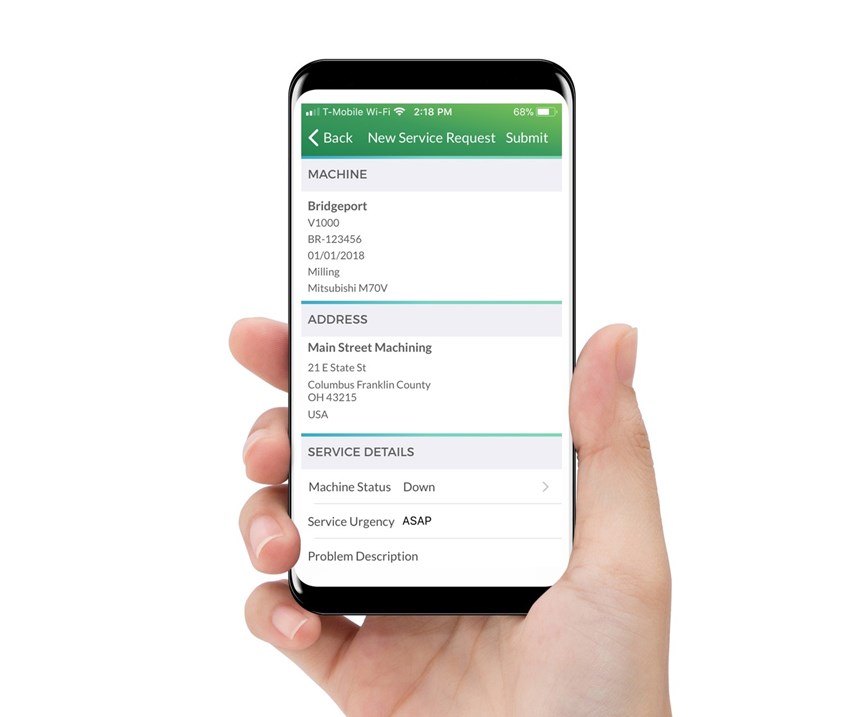

Independent machine tool service providers could be an answer to this dilemma. The problem is finding and evaluating these providers on short notice. The Up! app (the name refers to machine tool uptime) aims to address this problem, connecting machine tool service needs with providers able to address them. The recently introduced app is available through both Apple’s app store and Google Play, and a desktop PC version is also available.

“We are like Uber for machine tool service, but with a difference,” Mr. Vinod says. “The difference is, we are not bringing new providers into the market. We are going to established providers and making them visible to machine shops.”

The app focuses on independent, third-party service providers, he says. During its initial launch period, coverage was limited to Ohio, Indiana and Kentucky, and that head start means participation is still best in these states. More than 70 independent service companies within these states have registered with the app, all of which are available to offer bids on machine tool service within the geographic reaches they cover. The app has just recently gone national, so service providers from around the country have now begun to join as well.

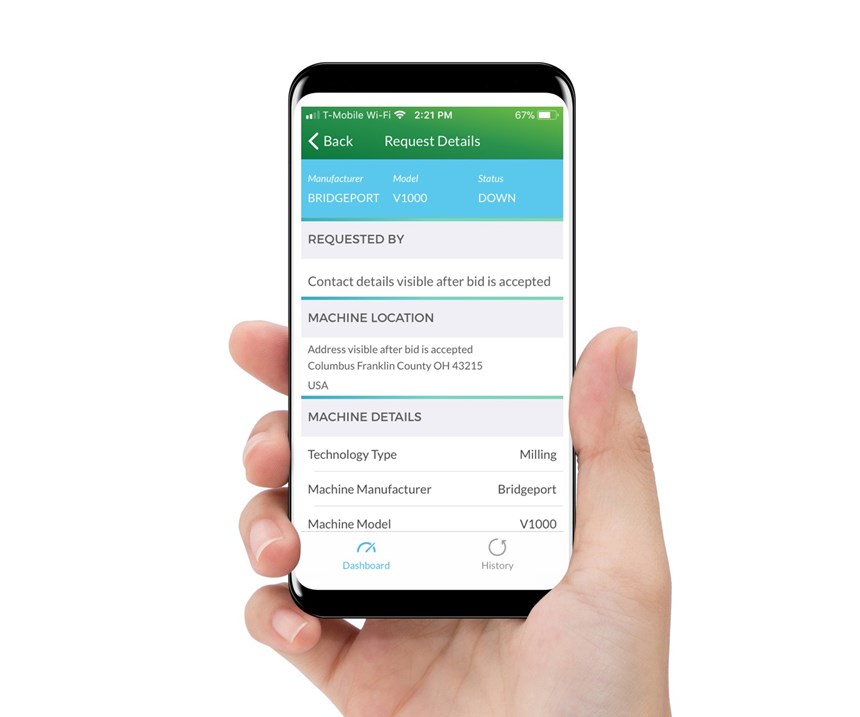

Service requesters—that is, machine shops—use the app by entering their machine tools by OEM and model number. When one of these machines needs service, the user can then enter a description of the need. Service providers knowledgeable about that machine type can reply through the app to offer a quoted price and date of service. Information available about every service provider responding this way includes whether the company has liability insurance, whether it has worker’s compensation insurance and the provider’s rating (out of five stars) based on other app users’ feedback. The machine shop also sees contact information, enabling it to engage the service provider directly to work out details before the offer is accepted.

The app is free for all parties to use, and its developers do not take a sales commission. The app's creators expect to earn revenue from the app through sponsorships.

“Right now, our biggest obstacle to adoption is the loyalty manufacturers have to their current service providers,” Mr. Vinod says. With good reason, shops prefer to stick with the machine tool suppliers. The challenge for these shops, and the opportunity for other service providers, comes when the need is urgent. “That’s why I don’t expect that price will be the driver that wins most bids,” he says. “I think the bids in our app will be won largely on availability.”

Related Content

Tips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)