Lessons About Metal Additive Manufacturing from a Hands-on Class

The metals you’re used to may not be the metals you want to 3D print. This and other lessons from the Additive Manufacturing Institute of Science and Technology (AMIST).

Share

A participant in the AMIST’s metal additive manufacturing class vacuums unsintered powder out of a 3D printer. This introductory course combines hands-on learning with big-picture lessons about AM.

Integrating metal additive manufacturing (AM) into an existing metalworking business requires new equipment, skill sets and workflows. But it also means taking a good hard look at the parts being produced to identify which are the best use cases for AM. Not every part that can be 3D printed should be, so one of the core challenges new users face is selecting the right ones.

“Use metal AM as appropriate to bring value to the enterprise. It doesn’t need to be 80% uptime — when you need it, you need it,” says Ed Tackett, director of educational programs for additive manufacturing (AM) at the Additive Manufacturing Institute of Science and Technology (AMIST). Part of the AM capabilities located at the University of Louisville, the AMIST functions as R&D lab, 3D printing service provider and, most importantly, a training center for students and professionals.

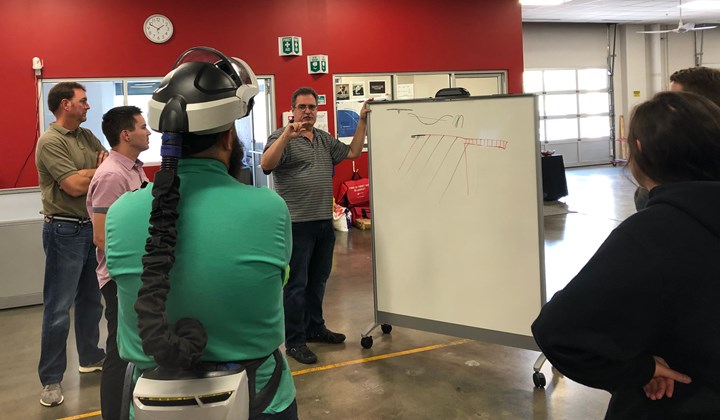

Ed Tackett (at the white board), director of educational programs for additive manufacturing, speaks to a group of class participants and University of Louisville co-ops about metal additive manufacturing at the AMIST.

Mr. Tackett’s statement about finding value is one of the lessons conveyed during the Institute’s metal 3D printing class offered for manufacturing professionals. In the fall of 2019, I sat in on a portion of this class, a five-day course targeted toward future machine operators as well as managers and other professionals who need to understand metal AM. The curriculum is a combination of classroom discussions, demonstrations and hands-on work. Attendees have the opportunity to set up and run prints on the AMIST’s direct metal laser sintering (DMLS) 3D printers, but also participate in less-glamorous tasks such as vacuuming unsintered powder out of the build chamber, leveling the build plate and removing support structures by hand.

There would be no way to cover every aspect of metal AM in so short a time, but the class goes a long way toward exposing attendees to its capabilities, requirements and dangers. Mixed in with the granular lessons about when to change filters and how to install recoater blades are big lessons about when, how and why to use metal additive manufacturing. I’ve summarized just a few of these big-picture points below:

- To identify AM use cases, consider benefits beyond part geometry. Lightweighting, assembly consolidation and part count reduction are all good reasons to use AM, but there may be other hidden benefits to be found. GE’s LEAP fuel engine nozzle, for instance, is famous for consolidating 20 parts down to one. But the “invisible” advantage this provides is in inspection. Where previously each individual component of the assembly would have been inspected, there is now just one piece — which saves considerable time and cost.

- The metals you’re used to may not be the metals you want to print. Aluminum is one example — it tends to be trickier to print, and requires a higher laser power because of its reflectivity. Unless the part requires aluminum for thermal properties or some other characteristic, other materials such as titanium may deliver better 3D printed results.

- Prepare for trade-offs. “Between speed, density and surface finish, you can choose two,” Mr. Tackett says. Metal 3D printers can produce parts as dense as castings or better, but that likely means slowing the print speed with better surface finish as a result. Or, the print could be optimized for speed at the expense of density and surface finish. Prioritize the most important requirements for each part, but also recognize workarounds. If the part will be finish machined after the fact, a rough surface finish might not be a problem.

- Account for postprocessing steps in the design. Most metal AM parts will need machining, so consider this in the design step. For instance, print tabs or add flat surfaces onto an otherwise organic part so the machinist has a way to fixture it later. Add a datum for inspection that can be quickly machined off later. “At the end of the day when that platform comes out of the printer, it’s metalworking,” Mr. Tackett says.

- By the time a 3D printed part gets to finish machining, it has achieved most of its added value. A metal 3D printed part is likely to be a near-net shape component, more like a casting than a blank. If something goes wrong downstream, replacing the print may be costly. Organizations should therefore utilize skilled machinists to finish 3D printed parts, or they risk paying for the workpiece twice.

Related Content

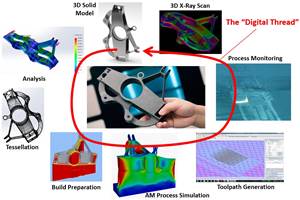

Go Digital: How to Succeed in the Fourth Industrial Revolution With Additive Manufacturing

The digitalization of manufacturing is set to transform production and global supply chains as we know them, and additive manufacturing has been leading the way in many industries.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreIn Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read More6 Trends in Additive Manufacturing Technology

IMTS 2024 features a larger Additive Manufacturing Pavilion than ever before, with veteran suppliers alongside startups and newcomers at the front of the West Building. As you browse these exhibitors, as well as booths found elsewhere at the show, keep an eye out for these trends in AM.

Read MoreRead Next

Additive Manufacturing and Metal Casting

A hybrid approach to consider.

Read MoreWhat Is it Like to Study Additive Manufacturing?

This article and video series filmed at Penn State University illustrate what the school's first master’s students in AM are learning, and how they’ll apply it to advance 3D printing.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=150)