Additive Manufacturing and Metal Casting

A hybrid approach to consider.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

According to the American Foundry Society, metal castings can be found in 90% of all durable goods, and you are seldom more than 10 feet away from a casting. I didn’t believe it at first, but if nearly every car, truck, train, tractor or construction vehicle has a casting in it, not to mention all the castings found in our infrastructure (buildings, pipelines, etc.), then you understand why that number is so high.

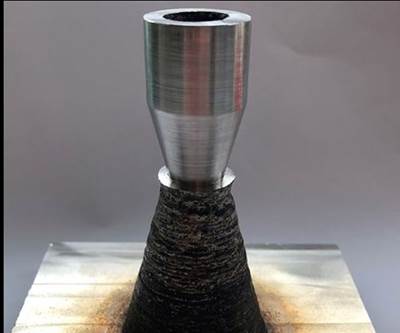

So how is additive manufacturing (AM), one of the newest manufacturing methods, disrupting metal casting, the oldest manufacturing method? It is pretty simple actually, and it goes along the lines of what we have been discussing recently, namely, hybrid manufacturing approaches in which AM is being used to create the fixtures, jigs, and/or tools (in this case, sand molds and cores) that are then used to manufacture parts by conventional means (in this case, metal casting). In fact, 3D sand printing is probably one of the easiest and least risk ways of integrating AM into production. We know how casting works; all we are doing is finding a faster and cheaper way to make the molds for them, and then we cast and finish components like we have been doing for hundreds of years.

For casting, the AM process of choice is binder jetting – a process in which a liquid binder is used to “glue” material together layer by layer to create a part. In this case, the material that is being 3D printed is sand, the binder is foundry-grade resin and the part is the sand mold or mold core. A part is designed in CAD as usual, but instead of turning it into a pattern, the 3D solid model is inverted to make a negative of the part. Then risers, sprues, runners and gates are added, and the resulting 3D solid model is of the mold itself, which is then 3D printed using binder jetting.

Binder jetting systems are readily available in the market right now. While many options exist, ExOne and Voxeljet offer binder jetting systems specifically tailored for 3D sand printing. Meanwhile, newer entrants like Viridis3D from EnvisionTEC combine robotic arms and binder jetting technology to print molds and cores as well as investment casting patterns.

Like most AM processes, using binder jetting for 3D sand printing gives you new design freedoms that you did not have with traditional casting processes. For instance, you don’t need a pattern anymore; you just print the mold directly. This saves time, and it also means that you don’t have to worry about draft angles and undercuts anymore, because you don’t have to remove a pattern from the mold. Better yet, cores can be printed directly into the sand mold, mitigating the alignment issues that plague so many castings. Meanwhile, risers and sprues can be optimized for improved flow since their geometry is not constrained by how the mold is made. In fact, the results that my colleagues Dr. Guha Manogharan and Dr. Paul Lynch at Penn State are reporting for novel sprue designs tested with Tony Badamo and the team at Hazelton Casting Co. are staggering: 99.5% reduction in casting defects, 35% reduction in inclusions and an 8.4% increase in mechanical strength. With improvements like these, metal casting may find new uses by companies that previously dismissed the technology.

At a cost of $0.10 to $0.15 per cubic inch, binder jetting sand molds and cores for metal casting is probably the most cost-effective AM process on the market right now. Add to that the speed with which a sand mold can be printed, not to mention the time savings from not making patterns, and the business case for metal casting with 3D sand printing is radically different. New designs for cars, trucks and construction vehicles can now be rapidly prototyped and iterated using functional components made via 3D sand printing, not to mention the more complex geometries that this form of hybrid manufacturing enables.

The metal casting industry may not be known for its speed, but the economics and opportunities are just too good to ignore. The question now is: Are you going to be ready to iterate this quickly on new designs and parts? If your parts mate with or assemble to castings, then you too will be asked to respond quickly and iterate faster thanks for AM. Meanwhile, if you process or finish castings, then the amount of work you do is going to change. Iterations will increase, but 3D sand printing also reduces errors, rework, and the amount of finishing and machining that is needed. What impact is that going to have on your bottom line?

Related Content

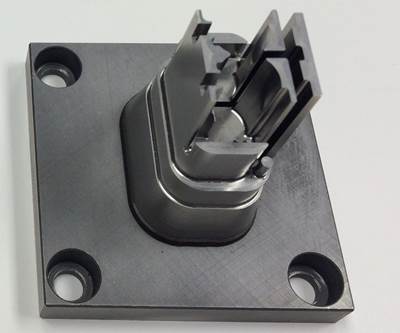

In Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreJTEKT Technology Days Showcases Synergies

The event took place following the company’s completion of its new showroom and decision to merge several of its brands under the JTEKT name.

Read MoreHow to Meet Aerospace’s Material Challenges and More at IMTS

Succeeding in aerospace manufacturing requires high-performing processes paired with high-performance machine tools. IMTS can help you find both.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreRead Next

Additive Manufacturing for Hard Tooling

Hybrid manufacturing is enabling tooling to be made with additive processes.

Read MoreCombining Additive and Subtractive Processes for Hybrid Machining

At this point, we are still learning how to combine the two to optimize hybrid manufacturing.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)