Share

Hwacheon Machinery America, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

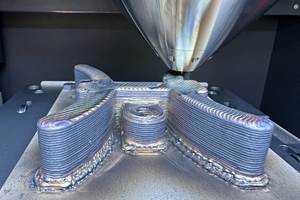

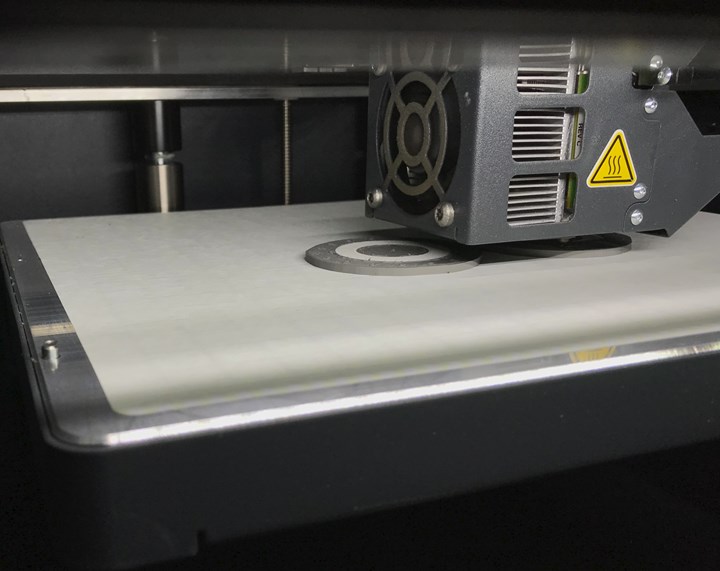

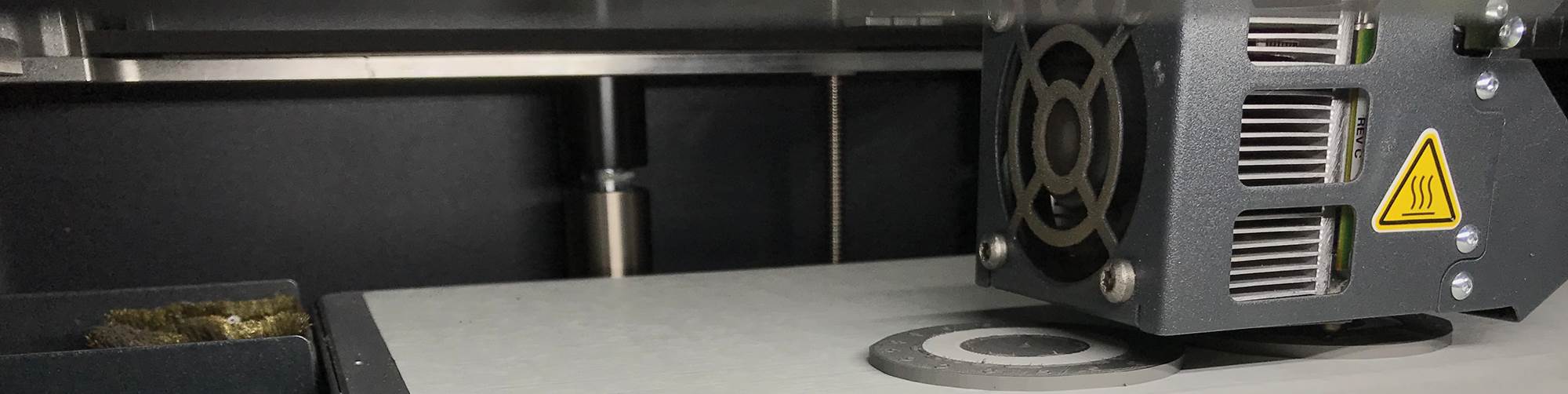

The Metal X is a fused-filament fabrication printer that builds parts by laying down layers of material, until a part builds up. Photo: Paul Hayes

If you would’ve visited Able Tool before 2003, you never would’ve pegged the Cincinnati-area machine shop as one actively investing in the latest manufacturing technology. Back then, a quick glance around the shop would show mostly toolroom-style equipment. However, that began to change when Paul Hayes took over as company president. For the business to thrive, he knew the operation would have to take a quantum leap by adopting much more advanced technology. Today, Able Tool’s shop floor consists of four- and five-axis machining centers and large horizontals and wire EDM. On-machine spindle and tool probes have reduced setup time on that equipment and enables in-process inspection for more effective process control.

The company’s commitment to adopting new technology didn’t end there. About six years ago, Mr. Hayes decided to take additive manufacturing from a concept he’d researched to a process he could possibly apply on his shop floor, ultimately moving quickly from 3D printing plastic parts to printing metal parts. To be certain, there’s a case to be made for printing each type of material, depending on the application, he says. In both cases, though, Mr. Hayes believes additive technology has helped his company better serve its customers by reducing the number of steps it takes to move from design to produced part. “Really, it’s just another arrow in our quiver, so to speak, to make things as efficient and cost effective as possible,” he says.

Not to sugar-coat it, investing in additive manufacturing was a risky move for Able Tool. While there is a clear ROI for more advanced machine tools and related equipment, additive technology’s ROI is murkier, especially for a shop not immediately using it for production. Yet, Mr. Hayes was determined to make sure Able Tool wasn’t in a position of playing catch-up again. In order to get ahead of the additive learning curve, he decided to take a leap of faith.

Graduating to Plastics

Able Tool is a milling, machining, fabrication and assembly shop that specializes in high-mix/low-volume production for a range of industries, applications and materials. Its facility boasts large horizontal mills, vertical machining centers and vertical turning lathes. Increasingly, the shop has been involved in full machine assembly, integration and testing rather than just individual part production.

Although additive capabilities are relatively new to Able, Mr. Hayes began looking into the technology about 15 years ago. He even hired a consulting firm to see if metal 3D printing technology was something his company should invest in, and two separate groups told him no. “They were probably right given the manufacturing environment at the time, what our company does, and the value associated with additive technology,” Mr. Hayes says. “None of those things aligned.”

Not to be deterred, Mr. Hayes continued to study the technology, convinced of its potential. Six years ago, he decided to purchase a MakerBot 3D plastic printer because it was a relatively small investment, the machine could sit on someone’s desk and no ancillary equipment was necessary. With the only consumable being the plastic material, Mr. Hayes says the MakerBot was a low-risk option for hands-on learning. If a part didn’t turn out as planned, or if it had to be scrapped, he didn’t have to worry about throwing away a high-priced metal experiment.

This was the first iteration of a two-piece, 3D printed plastic coolant ring designed to better distribute coolant to the tool tip on Able’s new boring mill. The problem is that the coolant manifold sits far back from the spindle, where the tool is. This device is designed to clip onto the spindle housing, allowing coolant to flow through its inner chamber and come out the two rings onto which Loc-Line flex hoses snap. Coolant can then be directed more efficiently to where the tool engages the material.

Four years later, Able invested in a Prusa 3D printer to produce closer-to-end-use parts. Two main features drew the company to the Prusa, says General Manager Mike Trovillo. First, it can print with more than one variety of plastic. Second, its heated build platform keeps the plastic warm to prevent warping. The company has used this machine to make a couple end-use parts for its customers, such as end-of-arm tooling for a robot and part nests for a CMM. Mostly though, Mr. Hayes says he uses it as a low-cost option for proving out concepts that would take time away from other jobs on his CNC machining centers or be cost prohibitive to make in metal. In some cases, the application simply merits a plastic solution. For instance, during my visit, a summer intern was working on the second iteration of a design for a two-piece manifold that would attach around the spindle housing of a large boring mill to help better distribute coolant to the point of the cut using coolant flex hoses that attach to it.

Able to Print with Metal

After gaining experience with printing plastic and seeing the technology that was emerging, Mr. Hayes decided the time was right to take the next step and begin 3D printing metal parts. “We had to rip the Band-Aid off and at least try to understand how we could use metal additive technology and sell it to our customers,” he says.

Though Able Tool had been building up to this moment for years, actually buying its Metal X 3D printer from MarkForged was a sudden move. At the end of last year, Mr. Hayes jumped on the opportunity to buy the new machine from Reynolds Machinery in Dayton, a new MarkForged distributor.

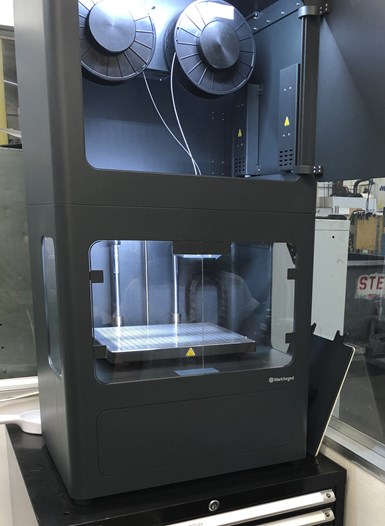

Despite the swift timing, Mr. Hayes was confident that this was the right decision for his company. Rather than choosing a laser-sintering or powder-bed machine, which would require a special lab environment, the Metal X has a lower barrier to entry and can make complex parts in its 300- by 220- by 180-mm build volume, he says. Also, learning from his experience printing with plastic, he knew he wanted the freedom to print with a variety of metals. Currently, the Metal X can print 17-4 PH stainless steel, H13 and A2 tool steel, but MarkForged plans to soon add the capability to print D2 tool steel, titanium, Inconel, copper and 316 stainless steel (which Able is particularly interested in) in the near future.

The Metal X uses both metal and ceramic powder to 3D print parts. The material comes in spools of powder encased in plastic for easier handling and a lower melting point.

The Metal X is a fused-filament fabrication (FFF) printer that uses spools of metal powder and binding agent enclosed within a plastic encasement. The second spool is ceramic powder enclosed within a plastic encasement. It works by feeding those spools through a heater block, where it is heated to the encasement’s melting point and fed through an extrusion nozzle. The nozzle first lays down layers of material mixed with ceramic where necessary, which will later act as the part’s release. (The ceramic can also be used to build support structures that once again will be removed at a later point). The nozzle then lays the metal on top of that, building the part layer by layer. The machine uses disposable print sheets that are held down by a vacuum table to improve bed adhesion and ease part handling. Once a part is printed, the paper is easily removed from the vacuum table. Able Tool’s typical batch sizes range from one to four parts. However, Mr. Trovillo says that if a part is small enough, he estimates that he could fit as many as 30 parts on the build plate. “It really depends on the size of the part,” he says. “You can print whatever fits in the build volume.” The shop’s smaller parts print in about two to three hours, while the larger parts can take several days, depending on part mass and complexity.

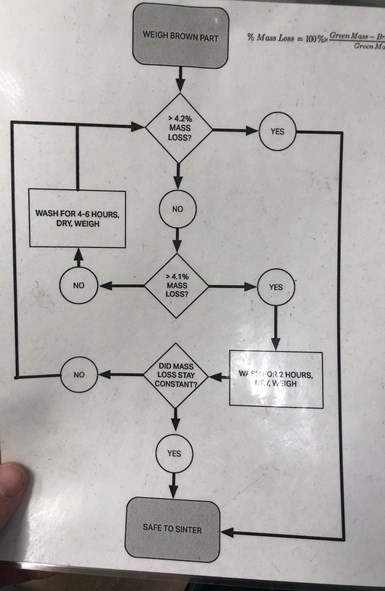

MarkForged provides this flow chart to guide users through the washing/sintering process. A printed part must be weighed before it goes into the wash in order to compare the percentage of mass lost during the washing process. Paul Hayes writes that weight on the bottom of the part for tracking purposes. If more than 4.2% of mass is lost, the part can be sintered. If not, it might need to be washed again.

Printed parts are weighed on a digital scale before being submerged into the MarkForged Wash-1 heated washing system, where Opeteon SF-79 cleaning fluid circulates around the parts to break down most of the plastic and wax binding agent. After washing, the air-dried part is weighed again to determine if a high enough percentage of the binding agent has been removed. If not, it goes back into the wash to remove more binder. If it has, the part is considered ready to be sintered.

Parts are placed on a ceramic tray and placed into the MarkForged Sinter-1, which has a 4,760-cubic-centimeter working volume. Although this is smaller than the maximum build volume of the Metal X, the company could send parts to an outside vendor for sintering. The purpose of sintering, which takes about 25 hours, is to fuse the metal powder into a solid metal. It also makes any of the printed ceramic very brittle. Once sintered, the part can snap off of the ceramic support structure and then be finish-machined if necessary.

Before building a part, the printer lays down a support raft, which will act as the part’s release. The print sheet is held by a vacuum to the print table to make part handling easier. Photo: Paul Hayes

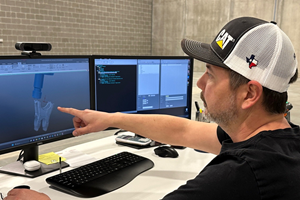

For Mr. Hayes, one of the advantages of using the MetalX was that it is basically a pre-packaged system – MarkForged supplied the printer, washing system and sintering oven, and directs shops in the specifics of how to set them up, paying close attention to ventilation, equipment spacing and sintering gas mixture requirements. MarkForged also offers its Eiger 3D-printing software, which Mr. Hayes says is very easy to learn. Once a part is designed in CAD software, its STL file can be uploaded to the Eiger software, which uses algorithms to automatically compensate for the shrinkage a part experiences during the sintering process. The Eiger software enables him to manipulate the part and see the dimensions, print time, wash time, sinter time and more.

Able Tool keeps its 3D printing system mostly inside this vented room on its shop floor. After printing a part, the part is weighed and taken to the washing system outside the room (foreground). It is then air dried and walked back into the enclosure to be reweighed. From there, it goes into the sintering machine, located almost in the middle of the room, to fuse the metal. A large argon tank for the sintering machine is located in the corner to the left of the Metal X.

A Brave New World

Within a week of Able purchasing the Metal X, the printer began to open doors for new business. A medical customer happened to notice it during a tour of the shop and began asking questions about its capabilities. Not only did that client award the machining work it came to investigate in the first place, but it also gave Able a job printing a metal prototype for a part – marking the first time the company had done any work for that customer.

Paul Hayes writes that weight on the bottom of the part for tracking purposes.

Other customer prototypes are usually the result of Mr. Hayes printing parts for his customers as a surprise to show them what this alternate part-production technique is capable of. But for now, Able mainly uses the Metal X printer for custom fixturing to be used around the shop. According to Mr. Hayes, use of the metal 3D printer intentionally has been a slow, organic growth path. In fact, the shop doesn’t even promote its additive capabilities on its website yet. “I want to be able to go to a customer with certainty and say that we can produce the part you want before we officially promote the capability,” he says.

Moving forward, Mr. Hayes hopes to use metal 3D printing capabilities not to go after new business per se, but to solidify the relationship he has with his current customers by helping them see design improvements and ways to produce parts more efficiently. He believes additive technology refinement will continue to the point in which it is just part of a machine shop’s everyday operation. Mr. Hayes predicts that most machine shops will have a 3D printer at some point, much like they have an three-axis VMC. “I believe the integration of additive technologies into a job shop environment is a matter of ‘when,’ not ‘if.’ We need to understand how to use these tools to meet our customers’ needs. That’s why we bought the machine.”

Related Content

A Fond Farewell to My Additive Friends

In his final “Additive Insights” column, Tim Simpson reflects on how additive manufacturing has progressed in the last six years. Standards and software are two examples.

Read MorePush-Button DED System Aims for Machine Shop Workflow in Metal Additive Manufacturing

Meltio M600 metal 3D printer employs probing, quick-change workholding and wire material stock to permit production in coordination with CNC machines.

Read MoreHow to Meet Aerospace’s Material Challenges and More at IMTS

Succeeding in aerospace manufacturing requires high-performing processes paired with high-performance machine tools. IMTS can help you find both.

Read MoreDigital Transparency in Machining Key to Multi-Site Additive Manufacturing

Cumberland Additive’s CNC programmer in Pennsylvania spends most of his time writing programs for machine tools in Texas.

Read MoreRead Next

FFF 3D Printing for Metal: Sintering Can Wait

Separating 3D printing from high-temperature processing is part of how the Markforged Metal X realizes a price less than established metal AM equipment.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=150)