A Convergence of Construction and Manufacturing

Digital tools for the construction industry have their counterpart in applications for manufacturing. Manufacturing companies should keep an eye on how the construction industry is managing the digital transformation.

Share

Autodesk, Inc.

Featured Content

View More.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View MoreAt Autodesk University (AU) last November, it was not surprising that several speakers representing the company, including CEO Andrew Anagnost, discussed the convergence of design and manufacturing. This has been a theme at several prior sessions of the annual AU event. However, another convergence was suggested—that of construction and manufacturing.

At first mention, this convergence might seem unlikely. Building buildings and producing products do not seem to have very much in common. Rarely is the construction industry cited in manufacturing circles as a model or comparative case for the direction in which manufacturing ought to move. However, that construction might adopt some of the concepts and technology that are transforming manufacturing is more than speculation, Autodesk spokespersons say. The trend is already underway.

What if building contractors could use robots to manufacture structural components on site in unattended cells? An example of such a cell was on display at the AU event. In this cell, a robot automatically manipulated a powered head that extruded a composite material made up of loose sediment (soil, dust, broken rock, and so on) that can be fused with recycled plastic. The sediment, known as regolith, is said to be widely found on Earth, other planets, the moon, and perhaps even asteroids. By precisely controlling the flow of extruded material, the robot built up a sturdy block approximately the size of a picnic beverage cooler. This block was individually shaped to interlock with other, similarly produced blocks designed to fit together as a wall, subfloor or a domed, igloo-like roof.

This process was not unlike robotic cells designed to 3D-print entire car bodies as shown at recent manufacturing trade events such as the International Manufacturing Technology Show (IMTS).

If we can additively manufacture a car, why not a house or the shell of a factory? In concept, 3D-printed building blocks could be loaded on an automated guided vehicle and delivered to a crane-like robot that puts them in place to construct a shelter, a storage unit or a support structure of some kind. Artwork at this display showed how similar cells might be deployed on the moon or on Mars to build a habitat or other facilities remotely to await the arrival of a crew of astronauts from Earth. It was suggested that the raw material for these 3D-printed building blocks might be scooped directly from the surface of the moon or planet.

This trend has significance for manufacturing as well. Erecting a building is essentially an assembly process involving a great number of components, many of which are one-of-a-kind pieces designed and fabricated to fit with multiple mating parts. In many respects, a modern jetliner is no different. Likewise, the construction industry faces many of the same challenges that lie before the manufacturing industry. These challenges include the integration of additive and subtractive processes; collaboration on an integrated, fully digitalized and decentralized ecosystem; thorough implementation of automated/unattended production processes; process verification and quality assurance; and management of the total customer experience.

It appears that many of the digital tools Autodesk is developing for the construction industry have their counterpart in applications for manufacturing. Manufacturing companies should keep an eye on how the construction industry is managing the digital transformation. It’s an opportunity to see problems and solutions from a fresh and enlightening perspective.

Read Next

Generative Design Generates New Interest in a Range of Manufacturing Options

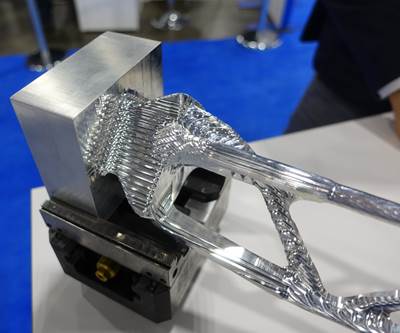

New developments in generative design can help companies make better decisions about part design by including manufacturability as a key value. CNC milling, for example, not an additive process, might come up as the better choice for making a complex part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)