10 Takeaways on How Artificial Intelligence (AI) Will Influence CNC Machining

The Consortium for Self-Aware Machining and Metrology held a promising first meeting at the University of North Carolina Charlotte. Here are my impressions.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

At the University of North Carolina Charlotte (UNCC), I recently attended the debut of an exciting new machining-related event where machining had to be explained to some attendees. The inaugural meeting of the Consortium for Self-Aware Machining and Metrology (CSAM) brought together manufacturing experts with mathematicians who had little basic familiarity with machining operations, all with the goal of advancing the development of, in the words of meeting organizer Dr. Tony Schmitz, “production systems with the ability to know their own state and respond.” In short, this was a conference entirely focused on uniting machining with artificial intelligence (AI).

Of course, the manufacturing people in attendance needed basic instruction also. I was one of those. The hope of applying AI to manufacturing is still in its early stages, and one of the first steps is just to figure out what the one might mean for the other. After absorbing the meeting’s day and a half of expert presentations and roundtable discussions, here are the impressions and lessons I took away related to the promise of AI assisting machining:

1. AI is not new, but it is current now because of large data sets and the power to process them.

Dr. Noel Greis of North Carolina State University explained this point. AI needs data. Today, we not only have increasingly cheap and effective sensors for gathering data, but also have graphics processing units (GPUs) for rapid calculation. She says the Big Bang moment for contemporary AI came in 2009, when a deep learning network (see next point) was trained using an Nvidia GPU.

2. In manufacturing, AI generally refers to machine learning and the current mainstream is deep learning.

Unlike automation, in which the response to any input is anticipated and programmed, machine learning involves automatically seeking patterns in data through large-scale calculation in order to self-select appropriate responses. Deep learning is a category of machine learning that goes, well, deeper. Machine learning parses data using algorithms that directly need human guidance. But deep learning structures algorithms in layers, creating a learning system in which the findings at one layer advance and improve the decision-making power of another layer.

3. Just the terminology is tough.

I watched PhD professors at the CSAM meeting struggle with their uncertainty over whether they were correctly applying terms such as machine learning, deep learning and neural networks. I feel no shame if a mathematician says my definitions in the preceding paragraph fall short in some way.

4. A weakness of machine learning is its lack of explanatory power.

Machine learning finds correlations, not explanations, and correlation does not always imply cause and effect. Dr. Sambit Bhattacharya of Fayetteville State University explained how a potential vulnerability of machine learning is in the way it “makes spurious conclusions look deceptively good.” Thus, Dr. Schmitz explained how the application of AI to machining research at UNCC has involved a hybrid approach in which programming based on the physical understanding of the system guides the data learning from the outset.

5. AI reveals the importance and true nature of metrology.

We tend to think of measurement and inspection as simply the judge of the process, sizing up a feature to see whether it passes or fails. But metrology’s greater power is in process control, not quality assurance. AI needs data, and metrology is the science of converting manufacturing events and outcomes into data.

6. With AI, we will discover cause-and-effect relationships we have never seen before.

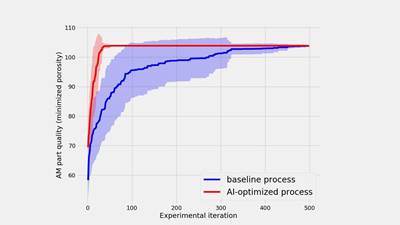

This point is the flip side of point 4. AI cannot give us explanations, but it will reveal phenomena that deserve explanation. One realm in which I am aware that this is happening is additive manufacturing (AM). The variables affecting an additive build are numerous and the interrelationships among inputs and outputs are not well understood, so machine learning is being used to more quickly discover the powers of different parameters. Correlations will be found and used in AM before they are explained.

7. AI allows experiments that would not otherwise be possible.

In a panel discussion, Dr. John Foltz of ATI Specialty Materials described the role of AI in materials development. Experimentation involving AI provides a way to, in a virtual sense, change just one microstructure property to investigate the effect while holding all other properties constant. Physical reality provides no way to do this.

8. Big organizations have an advantage.

No one stated this explicit point about AI, but it occurred to me as I listened to Dr. Jaydeep Karandikar of GE Global Research. He described the possibility of developing more sophisticated tool life predictions within GE by drawing information from every GE machined part. AI needs data, and big organizations potentially have a lot more data to marshal.

9. AI is an alternative to tribal knowledge.

Dr. Mike Vogler of Caterpillar sees promise in AI for workforce development. A wave of young new hires coming into manufacturing is producing a green workforce. In the absence of sufficient senior employees to guide them via tribal knowledge, he asks, “How do we augment the inexperienced worker?” AI is an answer, with its ability to learn and suggest correct responses in situations that otherwise might be too nuanced to be anticipated in programming or formal procedures.

10. Basic infrastructure is still needed.

What will it take to realize the full promise of AI in machining? A lot, but much of what is still needed is fundamental rather than elaborate. Dr. Foltz identified this. “We need the right sensors on machines to get us the data we need,” he says. Similarly, he pointed to the need for graphical interfaces for AI systems, so that these tools can be applied more easily instead of requiring coding.

Related Content

Investing in Automation, Five-Axis to Increase Production Capacity

To meet an increase in demand, this shop invested heavily in automation solutions and five-axis machines to ramp up its production capabilities.

Read MoreSame Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreRead Next

With Machine Learning, We Will Skip Ahead 100 Years

Machine learning or AI will prove vital to the advance of AM. Computational power will enable additive to advance much faster than if it had been invented in an earlier time.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)