You Can Automate More Than You Think

This shop expedites 3D milling work by reducing its dependence on employees for all of the information-related tasks that occur before the machining center can start to cut.

Share

With a CNC machining center you can just hit Cycle Start and stand back. Imagine if the whole machine shop worked that way. Imagine if the arrival of a customer’s geometry set in motion a series of unattended or lightly attended steps that resulted in the finished part being shipped out the door just a few hours later.

Now meet Richard Sweat. Mr. Sweat is the owner of a nine-employee machine shop that runs and ships 50 to 75 separate jobs per day. Every piece the shop machines is as unique as a snowflake, with a distinct 3D geometry unlike that of any other part the shop will ever machine. And every one of these pieces is delivered to the customer within 48 hours of when the geometry file arrives—within 24 hours if the file arrives before 5:00 p.m.

The shop is Southeastern Radiation Products of Sanford, Florida. The shop makes “tissue compensators” used in cancer treatment. These parts work like filters—or lenses—for radiation therapy machines. They give hospitals a level of control over radiation therapy machines far better than what they used to be able to achieve.

Mr. Sweat worked in radiation therapy physics for 8 years. He became a machine shop owner because he saw an opportunity in the improved scanning and modeling technology that started to become available to hospitals. Measurement technology today makes it possible to determine precise 3D coordinates for a cancerous tumor along with precise locations and densities for the healthy bone and tissue surrounding it. These data make it possible to design a metal fitting for the radiation head that uses variations in the thickness of the metal to vary the intensity of radiation, producing a radiation field conforming to the topography of the patient. Mr. Sweat even invented a brand name for this custom-machined part, calling it “Digitally Enhanced Compensation/Intensity Modulation with Aluminum.” That is, “Decimal.”

It would be difficult to imagine a more sensitive component. Patients in need of this kind of therapy need it now, so every order is an emergency order. And there is little room for error, because a machining discrepancy or a mistake in labeling two different orders would have severe consequences for the patient. These requirements threatened to limit the size of the business because the larger size necessary to take on more work would have introduced too much potential for error or delay. In short, the business wasn’t scalable. Or more accurately, it wasn’t scalable so long as the shop continued to operate the way a contract machine shop usually operates.

For the company to increase its volume, it needed to win more value from existing employees’ time. It needed an automated process that could deliver work to the shop floor with much less employee intervention. Automating machining was not the challenge—effective CNC machining centers took care of that. The challenge instead was to streamline the information-related tasks that have to be performed before a machining center can do its work.

Today that streamlined process has largely been put in place. Orders e-mailed to the shop are logged automatically, causing travelers to be automatically printed. Modeling and programming functions are so automated that CAD/CAM work takes 5 to 10 minutes per job. E-mail confirmations and shipment tracking numbers are sent to customers as soon as the job ships, without anyone in the company having to think about closing this loop. The system is close to hands-off—and for an independent shop, maybe about as close to hands-off as possible

This success at streamlining deserves examining for at least two different reasons. One is that it offers a model for other shops that may wish to automate their own information-related tasks.

But more fundamentally, SRP’s example suggests how broadly automation can be applied. This shop managed to automate various innocuous and “fuzzy” tasks that wouldn’t seem to be automation candidates. The implication, in other words, is that you can automate more than you think.

Today the reduced human intervention makes the process not only scalable, but also reproducible. Mr. Sweat can now imagine copying this shop in some distant location. In fact, he has begun to contemplate exactly this. For a business dependent on fast delivery, a facility in a separate time zone could be an important benefit.

File Translation

The streamlined process didn’t come all at once. It was developed in phases, and the phases unfolded over the course of years. The first phase—file translation—didn’t directly relate to automation at all. It was necessary just for the shop to be able to program any job.

The data files that describe a tissue compensator’s geometry don’t arrive in a format that a typical shop would recognize. There’s no IGES here. Instead the data come in about five different flavors for different makes of radiation machines, with coordinate measurements often given in centimeters, and point locations often defined using some non-Cartesian scheme such as a spherical coordinates.

Devising a translator to convert these files into models usable in CAM fell to Camcad Technologies of Winter Springs, Florida. Camcad is a reseller for the CAM software SRP uses—SurfCAM from Surfware—as well as a provider of postprocessors and manufacturing-related software automation. Mr. Sweat continued to employ the company for all of the phases that followed this one.

CAM Automation

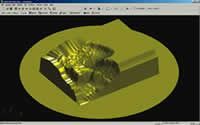

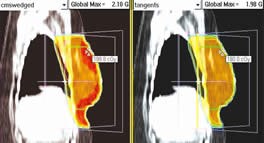

Photos in this article show what a typical compensator looks like. Changes in the radiation requirements of the patient’s body demand fluid changes in the thickness of the part, the result of which is a complex and seemingly random 3D form.

But this form isn’t the only critical feature. Also important is the engraved identification number that matches a compensator to its one and only correct patient. SRP composes this number by combining an ID string from the hospital with its own internal ID string. The combined string is added to the CAD model of the part on some flat surface area apart from the critical 3D form.

This task—placing the serial number—is one example of a function that wouldn’t seem to be a likely candidate for automation. The ID string is easy to import and easy for a programmer to eyeball into position. By comparison, automating the task is a challenge. It requires algorithms to be devised that can recognize surfaces of the part in ways that are instinctive and intuitive to the human eye. But without this automation, composing and placing the ID tag remained one more crucial step that was beholden to a human being. Automating any process consists of liberating crucial tasks such as this from human involvement, one small task at a time.

Another aspect of automating the shop’s CAM work was to define a library of machining strategies. At first this library would serve as an aid to the programmer’s thinking, but ultimately it would allow the strategies to be assigned automatically.

Populating the library began as a series of conversations among Mr. Sweat and the personnel from Camcad. They simply brainstormed, asking: What is every possible operation that might be involved in producing these parts? And: What rules determine the choice of tools and parameters these operations require?

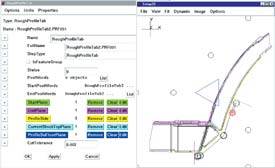

At first this information was captured using an Excel spreadsheet. The document became a foundation for process improvement, allowing the shop to devise test cuts for evaluating the chosen strategies. Thus the strategies improved. Today those optimized strategies reside in a database, and that database is linked to the CAM software by means of the software that lets the shop realize CAM automation.

Database Creation

Software created by Camcad now automates CAM programming in two important ways. It imports parameter and tooling choices from the machining database according to the geometry of the part. But first, it helps to define this very geometry by adding the unique 3D form to the standard portion of a compensator part. This standard portion is a disk-shaped plate whose size and hole pattern match the particular radiation machine. In addition to assigning machining strategies, the CAM automation pulls these standard elements out of a database populated with these forms. The result is that human programming time is reduced to 5 to 10 minutes per part.

Postprocessors

The next phase involved postprocessors, only because at this point the company bought new machines.

The shop has stuck with one supplier—Mazak—for its CNC equipment. However, it has learned to abandon certain basic types of machines. Horizontal machining centers in particular proved to be a poor choice. While an HMC is at its best when a number of parts can be run in one cycle using a tombstone fixture, SRP in practice was rarely able to wait for enough orders to fill a tombstone before it had to start cutting on the jobs it had. Realizing that verticals were better suited, the shop standardized on Mazak’s “Nexus” line of VMCs. The shop has purchased eight of these machines.

Camcad’s role in providing quality postprocessors was significant because creating NC code represented a link that clearly would have to run without a human hand. The shop’s streamlined process left no time for the kinds of glitches that might make it necessary to edit this code by hand.

Order Automation

Now the shop was ready to move away from CAM programming to automate other information-related steps. Entering orders is yet another function that is relatively straightforward for an attentive employee, but challenging to automate.

SRP’s orders arrive as e-mails with the geometry data in file attachments. Every one of these orders used to be opened and entered by hand. Today, custom software scans the e-mails as they arrive for information such as the hospital’s name, the radiation therapy machine type, and the patient’s ID string. The software also checks for redundant orders in case the same order was e-mailed twice. When it’s able to locate all of the information it needs, the software creates and prints the traveler for the shop floor.

Sometimes the software cannot find the information it needs. Orders the software fails to process are shunted to a holding file for employees to process manually. The problem may be as simple as a typo in the customer name or machine type . . . or else the problem (if that’s the right word for it) may be a first-time customer who has yet to be entered into the system.

In other words, the automation does not entirely do away with human oversight, but it doesn’t have to. The order-entry system succeeds not by processing every order, but instead by processing the majority of orders so that employees can spend their time only on the relatively small number that actually require human judgment.

The Shop Today

Implementing all of these phases covered a span of about 3 years. A next phase, still being planned, intends to automate QA documentation by pulling data from the CNC following inspection with the machining center’s probe.

Here are steps the shop has automated so far:

- Entering work received via e-mail

- Assigning a work order number

- Printing a traveler

- Completing the CAD model by assigning standard part features that surround the unique geometry

- Assigning machining strategies

- Decreasing cutting time by drawing upon machining strategies that have been refined through testing

- E-mailing confirmation and tracking information to the customer

The Shop Tomorrow

Today there is a limitation on SRP’s ability to provide next-day delivery. Because of the time-zone difference, the 5 p.m. deadline in local time translates to a 2 p.m. deadline for hospitals on the West Coast. Practically speaking, 2 p.m. is too early in the day for a hospital to have its measurements of a patient complete and ready to be e-mailed off.

So why not open a West Coast facility? In the future, Mr. Sweat says, his current shop may be one of multiple shops just like it.

In fact, a sister shop may be even farther than just three time zones away. Mr. Sweat has met with potential partners from Southeast Asia, Europe and South America. SRP’s tissue compensators bring a new level of effectiveness to radiation therapy machines that have been in service for decades, and this aspect of the product is particularly appealing in parts of the world where hospitals generally lack the latest equipment.

Mr. Sweat struggles with how he could maintain sufficient control over an enterprise located on a different continent and subject to a different legal system. That problem does not present an easy solution. But from a purely logistical standpoint, he says there is no reason why SRP’s procedures, databases and software could not be replicated right now to launch a similar shop across an ocean or in a different hemisphere.

Related Content

Refining Shopfloor Processes for Mission-Critical Parts

Pacon Mfg, Inc. has not rested on its laurels as the 2020 Top Shop Honoree for Shopfloor Practices and Performance. In the years since, it has refined its processes to continue excelling in a volatile market.

Read MoreERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

Read MoreCan Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRead Next

Empowering The Programmer

A project aimed at making military aircraft parts faster shows just how much productivity gain can come from automating the programmer's repetitive tasks.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=970;quality=90)