With Face Drivers, Shop Faces Long Cycle Times Head On

By switching from jaw chucks to face drivers, a manufacturer of large shaft components was able to reduce the number of setups, cutting cycle times on some parts from days to hours.

Share

Reducing the number of setups it takes to machine a part can improve both quality and cycle time. When Johnson Machine Works began investing in technology to improve quality and reduce cost per part, it discovered that by switching the workholding on its new multitasking lathe from chuck jaws to face drivers, it could reduce the number of setups for some of its larger parts, chopping cycle times from days to hours.

Johnson Machine Works has been in business in Chariton, Iowa, since 1907. Originally a repair shop for local farmers, the company has grown into a fabricator of large steel structures with clients all over the world.

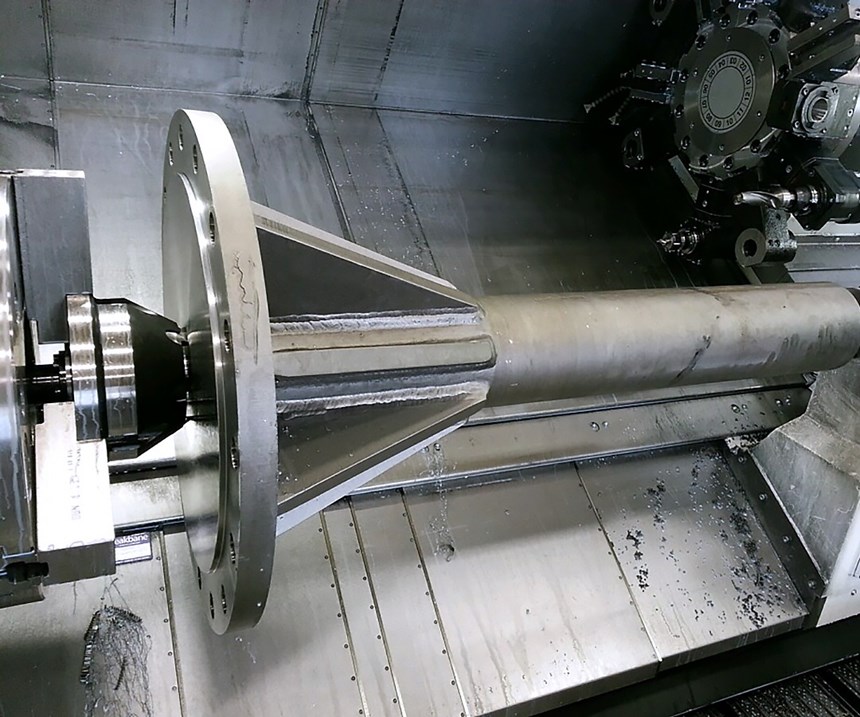

For years now, the shop has manufactured a range of large carbon steel and stainless steel shafts for various customers. Many are designed for use in critical applications and have tight tolerances for runout from end to end. One family of flanged parts is representative of the extensive setup and machining time that was required. A typical part in this family has a 2-inch-thick flange that measures 23.5 inches in diameter and a 6-inch-diameter shaft that is 45 inches long. The part’s runout tolerance might be +0/-0.001 inch. After two initial turnings on manual lathes, the shafts would undergo a horizontal keying operation before they were moved into a vertical position for drilling flanged bolt holes. Many of these steps required flipping the shaft around and reclamping it in a fixture or chuck. This often resulted in parts that exceeded allowable dimensional tolerances, requiring additional setup and machining time to restore accuracy. For some of the larger flanged shafts, the process to complete a single part would take as many as five days.

In need of a more efficient solution, Plant Engineer Kelley Werts reached out to Curt Block, Mazak’s Iowa sales manager, for an equipment evaluation. This grew into a process analysis, and in 2014, the shop purchased a Mazak Quick Turn Nexus 450M with live tooling capabilities. The new machine could reduce turning time, but the shop still needed to address the drilling and keying operations.

At Mr. Block's suggestion, Johnson Machine Works contacted Dan Reasoner of the Whittemore Co., the region’s representative for Riten Industries (Washington Court House, Ohio), who recommended that the shop replace its chuck jaws with face drivers for workholding.

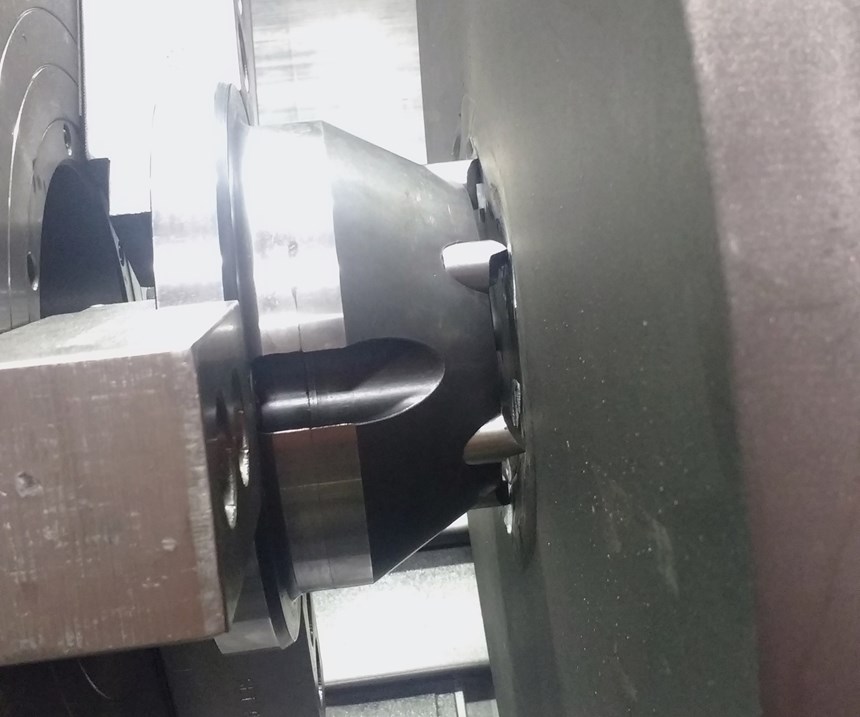

Face drivers employ chisel-edged drive pins that bite deeply into the end face of the workpiece under pressure from the tailstock and the cutting forces generated during initial machining. In contrast with chuck jaws, face drivers leave the entire length of a workpiece exposed for machining, eliminating the need for reclamping. This saves time and results in concentricity between centers, improving surface finish. With sufficient tailstock pressure, the correct drive-pin edge width and proper cutting tool forces, a face driver is designed to safely hold large parts: an important requirement for Johnson Machine Works.

The company chose two large, standard face drivers from Riten Industries—a flange mount and a 5 Morse taper mount—that accommodated the entire range of shaft sizes. With the correct selection of center points and drive pins, the face drivers could supply the required gripping force on all the necessary parts.

Mr. Reasoner was confident that the face drivers not only would be up to the task of aggressive turning, but that they would also enable the Mazak machine to perform secondary milling operations. What the shop previously had done on four machines could now be done on one—in a single setup—saving time and improving surface finish.

Because Johnson Machine Work's machinists limited experience with face drivers, only using them on older equipment to make smaller parts, Mr. Reasoner supervised the installation and machined a sampling of shafts of various sizes. He stayed with the operators until they were comfortable using the face drivers.

After a period of testing and adjustment, the new process proved to be a success. “This new setup has completely changed our approach to large-shaft machining,” say shop manager Tyler Ruepke. “The change-over from one shaft to the next is quick and easy. The quality is superior to our previous methods and the cycle time has been reduced from days to hours.”

According to Mitchell Kirby, Riten’s vice president of manufacturing, the 32-RMS surface finish the parts require is easier to hold with the new lathe and face drivers in comparison to the older equipment.

Initially, the face drivers were intended to machine screw pump shafts, but today the shop is using them for a variety of shafts in all areas of the business.

Related Content

CNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)