Wire EDM Machine Enhanced With High Precision, Intelligent Interface, Service Support

GF Machining Solutions spotlights the new CUT X 500 and CUT P 350 Pro wire-cutting EDM machines with heightened accuracy, precision and productivity at IMTS beside tooling, automation and software partner, System 3R.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

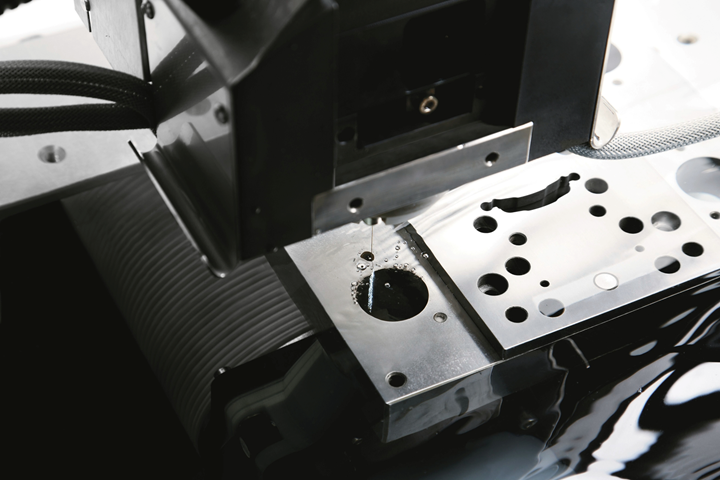

Photo Credit: GF Machining Solutions

GF Machining Solutions highlights advances in EDM technology, service, support, automation and tooling, all of which is designed to help shops solve their manufacturing challenges through complete solutions and holistic support. Moreover, in booth #338376, System 3R is showcasing tooling solutions to reduce setup time and automation solutions to maximize machining hours.

Integrated problem-solving solutions include the new Cut X 500 and Cut P 350 Pro wire-cutting EDM machines for precision part generation. To maximize machine-tool value and competitive readiness, GF Machining’s subscription-based Success Packs are said to feature comprehensive customer support as well as digital services that add connectivity for remote machine monitoring and troubleshooting no matter the location. Rounding out the lineup of live demonstrations will be an automated cell featuring a Mill 400 U and Form P 350 with a Fanuc robot. There will also be a System 3R WorkPartner 1+ modular pallet system connected to a GF Machining Solutions Laser P 400 U laser texturing machine.

With Intelligent Power Generator (IPG) technology, the Cut P 350 Pro delivers surface finishes as smooth as Ra 0.08 µm and heightens accuracy with integrated thermal regulation that maintains temperature at ±0.2°C. To accommodate heavy workpieces, the machine’s Quadrax mechanical system keeps the table, work tank and dielectric liquid stable.

In addition, the Cut P 350 Pro and Cut X 500’s Uniqua human/machine interface (HMI) is said to deliver optimal functionality and ergonomics in a 19" vertical touchscreen, full keyboard and mouse. Abundant automation options add to the machine’s scalable flexibility, with optimized production for electronics, automotive, medical and mold and die manufacturers through more than 600 pre-programmed cutting processes.

According to GF Machining, the AgieCharmilles Cut X series holds extreme accuracies in machining positioning and pitch. Developed to provide high precision and thermal stability in large runs of complex components, including stamping tools, multi-cavity molds and micro components, the Cut X 500 and all other Cut X machines feature adapted mechanical structures, dedicated machine calibration and testing to deliver pitch accuracy as low as 1.0 µm. High-precision axes, short measurement loops, dual measurement on all axes, consistent isolation of the EDM area from heat sources and submerged working areas optimize conditions for micro applications. Two-spool Automatic Wire Changer technology and an onboard Job Management System help further reduce processing time and simplify job prioritization.

From System 3R, GF Machining Solutions’ source for tooling, automation and software solutions, the WorkPartner 1+ (WPT 1+) scalable modular automation system reportedly maximizes magazine capacity for loading and unloading parts and electrodes, while conserving shop floor space. With flexible one-, two- or three-magazine capacities and fully integrated pneumatic control for gripping devices and table chucks, the WPT 1+ can serve one or two machines.

Related Content

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

-

Translating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

-

Increasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

.png;maxWidth=150)