Where Focus Is Foremost

A shop that specializes in precision thread grinding not only provides an environment in which its machinists can fully focus on challenging tasks, but also the advanced equipment needed to accurately complete them.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

Shopfloor policies differ from place to place, as one would expect. For example, I’ve visited successful shops that are okay with loud music playing over the din of manufacturing activity, “pin-up girl” photos on toolboxes and those sorts of allowances. However, I didn’t encounter any of that while visiting B&R Grinding’s facility in Franklin Park, Illinois.

There’s a reason for this, explains Richard Ruhl, president of the second-generation family business that specializes in precision thread grinding. It’s not because he doesn’t want his well-trained employees to enjoy themselves at the shop. Rather, he says it’s because the thread grinding and related work those machinists perform demand a high level of focus and concentration. That’s why he has worked to minimize distractions on the shop floor while providing a clean, organized and well-lit facility for employees who might be asked to “dust” a few microns off a part—a part that might be worth more than $60,000 before it’s handed to them for final grinding.

To be sure, scrapping an expensive part like that really isn’t an option.

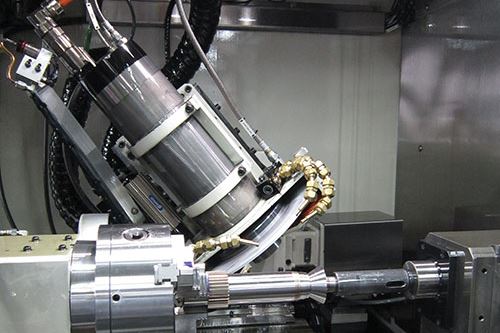

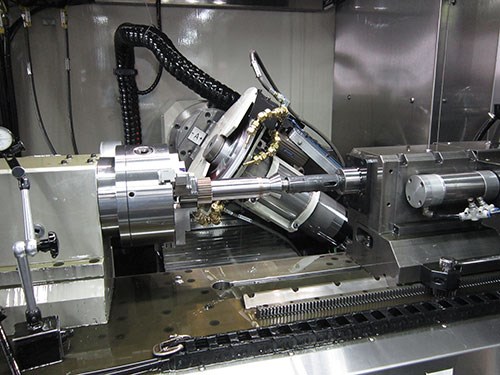

That said, maintaining a focused environment is only one piece of the puzzle. The work that flows through B&R is becoming increasingly challenging, so it is just as important to give employees the tools they need to do the tricky jobs they’re tasked to complete. For example, the shop has a number of optical comparators located near machines so machinists can easily access them to inspect parts. B&R also continually trains employees so they become comfortable and at ease performing tight-tolerance work. Mr. Ruhl wants them to become specialists in operating the shop’s advanced machining equipment, the latest of which is a new CNC linear motor thread grinding machine with 1-meter grind length and a 180-degree power helix. These two distinctive machine features are critical to meet the growing demand to thread-grind long parts with increasingly drastic thread helix angles.

Mr. Ruhl and Julio Espino, B&R’s general manager, discussed the importance of pairing a focused environment with capable equipment like this during a recent visit to the shop located just south of Chicago’s O’Hare airport.

Thread Grinding Roots

Richard Ruhl’s father, Bob, started the company in 1976. Initially, it was primarily a turning business, but he eventually steered the shop toward thread grinding to differentiate it from others that also predominately performed turning. Richard amassed a vast amount of manual thread grinding experience after joining the company in 1978 and became company president in 1993. At that point, he made a concerted effort to transition the shop from manual equipment to all CNC, a transformation he eventually completed through continuous reinvestment in the company.

Today, B&R performs turning, OD grinding and thread grinding of worm gears, lead screws, ballscrews and related components for applications that have high-accuracy motion control requirements. Hardness rating for components to be ground can surpass 62 HRc while typical lot sizes can range from a single piece to production volumes. The shop also completes a healthy number of collapsible molding cores for a key customer, performing OD grinding and buttress thread grinding on those products.

Much of B&R’s OD grinding work is performed on its two Mitsubishi PD32 cylindrical grinding machines that each feature in-process gaging and a 6-inch-wide wheel option, the latter offering the possibility to grind multiple diameters, shoulders and other features in one plunge. The shop also has five CNC external thread grinding machines from Drake Manufacturing (Warren, Ohio). In fact, its fifth and newest Drake represents a significant advance in thread grinding capability to meet the changing demands of its customers.

This GS:TE 200 external thread grinding machine, purchased in June 2013, is an example of a non-retrofit model that Drake designs per customer requirements and completely manufactures in-house. The machine with precision CNC taper correction of the tailstock can grind a wide variety of thread forms, including 60 degree, ISO, Acme, Gothic arch, Whitworth, buttress, full radius and worm (ZA, ZN, ZK and ZI forms). It can also grind ODs, angles and grooves. As Mr. Ruhl explains, the shop looks for versatility in the new equipment it considers, preferring machines that can perform multiple functions.

He also notes that this new machine has no problem routinely achieving grinding accuracy of 0.0002 inch. This is due in part to its mineral-filled, cast polymer base designed to damp vibrations and offer thermal stability. Its linear motor drives on the workhead and wheelfeed axes offer quick acceleration and fewer mechanical parts for low maintenance. In addition, each linear axis has glass scales providing 0.05-micron position feedback.

That said, perhaps the two most distinguishing features of B&R’s new machine are the 1-meter grind length and the 180-degree, CNC-controlled grinding wheel power helix. These two features are key in enabling the shop to thread-grind much longer parts than it once could (its previous limit was 24 inches of grind length with 40 inches of total Z-axis motion) while having the capability to accommodate the high thread helix angles it is encountering more these days, especially for worm gears. In the past, thread helix angles commonly didn’t exceed 35 degrees. However, B&R has since used its GS:TE 200 to grind threads with helix angles as high as 56 degrees. Plus, there’s a side benefit of having the 180-degree helix capability for this particular machine model. To accommodate the 180-degree rotation, risers were installed to lift the machine’s headstock and tailstock off the table by 2 inches, which increases workpiece diameter capacity from 7.87 to 11.87 inches.

Other notable features that enable this machine to attain micron-level grinding accuracy that I learned about during my visit include:

• Coolant filtration. A 250-gallon centrifuge filtration system removes swarf as small as 5 microns from the full-synthetic oil coolant used in this machine. This keeps contaminants from being introduced between the wheel and the workpiece, which would otherwise cause scratches. The oil is cooled to 70°F, too. This is important because some of that cooled oil is delivered through the machine’s headstock to ensure that the spindle maintains a consistent temperature and doesn’t expand during grinding, which would adversely affect grinding accuracy.

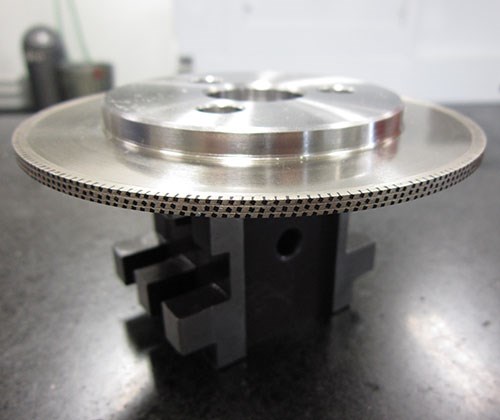

• Diamond rotary dresser. The GS:TE 200 features a 3,300-rpm diamond rotary dresser that wears significantly less than single-point diamond dressers and generates more accurate and repeatable wheel profiles, Mr. Espino explains. A tungsten matrix holds the diamond particles in place around the periphery of the dresser. Precise contour dressing is achieved as the rotating diamond dresser mounted on the worktable moves side to side in the Z axis and the X-axis wheelfeed moves front to back to form the desired profile. The shop uses two types of diamond rotary dressers, round-edge and square-edge versions, depending on the wheel feature to be created. The square-edge dresser is well-suited for creating tiny radii on crests, while the round-edge dresser is effective for flats and bottom rounds, Mr. Espino says.

• Programming commonality, capability. All the Drake thread grinding machines at B&R have some version of the builder’s PartSmart programming software, which simplifies operator training across different models. Plus, this menu-driven software is conversational, meaning operators essentially fill in the blanks for a given type of thread-grinding job. This makes switching to different thread styles simpler, Mr. Ruhl says, which is important, given the small-volume, job-shop-type work that B&R performs. He also notes that the software has flagged operators at times when improper data provided by the customer has been entered, preventing crashes or other potentially costly problems from occurring.

Mr. Ruhl says Drake was also able to customize the control interface per the terminology the shop prefers. For instance, B&R expresses angles in linear degrees rather than in degrees and minutes, and the software reflects that. Similarly, B&R refers to the operation that removes the sharp feathered edge at the end of a ground thread a “blunt start” instead of a “thread truncation.” In fact, the new machine can thread grind a part and perform a blunt start in one setup. Previously, a second setup and operation were required to grind the blunt start.

• Programming simulation. The software’s graphic visualization capability enables operators to view and verify a new profile to be dressed on a grinding wheel before the wheel is actually dressed. This has eliminated the need for machinists to first dress the wheel, then take an impression of the wheel profile and finally verify that impression using an optical comparator, as they otherwise would have to do.

Grinding (and Managing) Requires Patience

For machinists, performing precision grinding to put the final touches on expensive parts takes patience. Therein lies the value of quality equipment, effective training and a focused shopfloor environment. Similarly, Mr. Ruhl says his more than 30 years of thread grinding experience has made him an understanding manager, and the key in dealing with employees is patience. His patience comes through reflection about how he felt running machines and performing tight-tolerance work on the shop floor. He admits that isn’t always so easy, but the processes the shop has in place help ensure that employees have pride in their work and their workplace as they complete the high-value motion-control components that flow through the shop.

Related Content

High RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=150)