When You Need Really Accurate Bores

When bore specifications move beyond the capability of more traditional cutting operations, shops look to honing as the next step in the finish and accuracy continuum. Here you'll find a process that, in some applications, produces better results than honing can.

Share

For the majority of bores generated in the metalworking industry, a good boring bar and possibly a reamer or an internal grinder are sufficient to meet most tolerances. There are, however, some applications where these tools are insufficient in generating size, surface finish and micro structure requirements.

When bore specifications move beyond the capability of more traditional cutting operations, shops look to honing as the next step in the finish and accuracy continuum. Sunnen Products Company (St. Louis, Missouri) has a process that, in some applications, produces better results than honing can.

Sunnen calls the system Krossgrinding. It’s a coined word that indicates two of the primary advantages of the process. It combines the familiar honed crosshatch pattern in a bore surface, while removing relatively large amounts of stock quickly, like grinding.

The key to Krossgrinding is the tool. Like honing, the axial straightness of the bore being cross-ground is a function of the length of the tool. The length assures that any high spots in the bore are cut first.

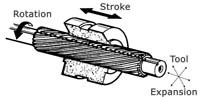

Roundness of the diameter is generated by the rotation of the tool and the tool’s freedom to center itself with the neutral axis of the bore. (It floats in the bore.) Reciprocation of the tool and application of constant cutting pressure throughout the tool’s contact area generate diametric straightness (freedom from taper) in the bore.

In the Krossgrinding process, these axes of motion, rotation and reciprocation are combined with the ability to precisely expand the diameter of the cutting tool. The tool that Sunnen has designed for its Krossgrinding process uses an expanding mandrel to increase the diameter of the cutter in the bore. This expansion is programmable increments of one millionth of an inch (0.000001") with control resolution down to one fortieth of a millionth of an inch. (0.00000025").

The expansion range of the cutter varies by its size. For example, a 0.375 inch diameter tool can be programmed from 0.371 inch to 0.379 inch. The largest Krossgrinding tool, 1.25 inches, expands from 1.240 to 1.260 inches.

For finish boring, in production, it’s the fine adjustments that are more critical to the process than the actual range of the tool. The spindle that carries the expanding mandrel tool uses a DC servomotor to actuate the mandrel drawbar. The servo runs through an anti-backlash reduction gearbox that attaches to an integral ballscrew in the spindle.

Design of the expanding tool is relatively simple. A horizontally slit sleeve covers a solid mandrel. Depending on the application’s surface finish, stock removal and crosshatch pattern requirements, rough, semi-finish or finish grits can be specified on the cutting tool. The sleeve has spiral channels (flutes) that run axially the full tool length for swarf removal. Krossgrinding is done wet, using coolant for most ferrous materials and oil for softer metals.

To deliver the tool to the work, Sunnen has developed a series of vertical spindle modular honing systems. These machines use standard components such as columns and carriers that can be tooled with fixturing, gaging and workpiece delivery systems to provide custom production solutions for precision boring applications.

Related Content

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreThe Impact of Cutting Teeth Spacing on Machining Stability

Many cutter designs are available, and variable teeth spacing (or variable pitch) cutters can be used to influence milling stability. Let’s discuss why teeth spacing affects stability.

Read MoreCustom PCD Tools Extend Shop’s Tool Life Upward of Ten Times

Adopting PCD tooling has extended FT Precision’s tool life from days to months — and the test drill is still going strong.

Read MoreForm Tapping Improves Tool Life, Costs

Moving from cut tapping to form tapping for a notable application cut tooling costs at Siemens Energy and increased tool life a hundredfold.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)