Wet-Machining of Composites Crosses Boundaries

Although composite machining has traditionally been performed dry, new coolant technology has proven to prevent delamination, increase tool life and reduce health risks.

Share

It is part of human nature to cross boundaries and set new records—to run a 100-meter dash faster than ever before, to fly even further into space and enter new realms. Speed can be an addiction. Like mountain climbing, going faster is its own reward, and carbon fiber reinforced plastics (CFRP) play a key role in reaching top speeds for various applications. That’s why it’s not surprising that CFRP material is used for aircraft, Formula 1 race cars and high-end bicycle components. In fact, the entire body of the Bugatti Chiron hypercar, in addition to other components, is made of CFRP, which lightens the vehicle, enabling it to reach speeds ranging to 261 mph.

However, while metal parts can be stamped in seconds, it can take several minutes for a CFRP part to be molded and cured. Plus, the longstanding approaches to machining CFRP have led to long machining times and also contribute to higher costs, as does the fiber material itself.

One of the common “laws” of CFRP machining is that traditional liquid coolants, particularly those that are petroleum-based, should not be used. This idea is based on fears that these coolants could degrade the material’s mechanical properties, which is why nearly all composite machining has traditionally been performed completely dry.

This had been the approach taken by Dusseldorf, Germany-based Capricorn, a specialist supplier in the automotive industry with six production facilities in four countries across Europe. Capricorn also manufactures components made of fiber composite materials and hybrid materials for the finest car manufacturers in the racing world as well as in the luxury sector, including Bugatti.

Until about a year ago, Capricorn only machined its composite components dry or with minimum quantity lubrication (MQL). However, its investment in an FZ33 Zimmermann CNC gantry milling machine laid the path to wet machining. In collaboration with lubricant manufacturer Rhenus Lub, a specialist in high-performance lubricants and greases located in Mönchengladbach, Germany, Capricorn tested and applied coolants in the machining process, achieving improved part quality, decreased machining time and costs, and increased operator safety.

Eliminating Health Hazards

The fine dust released during CFRP cutting is a particular cause for concern. High quantities of these fine particles can have a negative effect on the health of shopfloor workers. To avoid endangering employees, employers must install ventilation systems and filter systems in the workplace. “This equipment comes at a high cost, but it is mandatory to provide adequate protection against fiber dust,” explains Anna Lena Demmerling, part of the R&D team at Rhenus Lub. “It is also essential for machine maintenance: Carbon dust is electrically conductive and may affect electrical parts and increase wear on the spindle. Using coolants binds the dust together, improving health and safety conditions, and ensuring maximum acceptance of the process among process owners and machine operators. At the same time, the special flushing properties of the coolants keep the machine rooms cleaner.”

The fact that Capricorn can now machine without dust is a very important point for Tobias Lussi, milling machine operator. “There is no health hazard due to the fine dust particles, as they are all completely bonded by the coolant,” he says. “This makes my work much easier. I can now open the machine even directly after a machining operation and no longer need to wait until everything has been extracted.”

Dry Machining Pitfalls

Because carbon fibers are characterized by high strength, they are difficult to cut, and when machined dry, their low-heat-conductive and storage properties force relatively slow cutting speeds in order to maintain an acceptable equilibrium between heat generation and heat disposal. “Additionally, CFRP layups can easily delaminate on the exit side of a drilled hole, even though the speed and feed rate during processing are very low in comparison to the possible feed rate during wet machining,” Ms. Demmerling says. “The tools are also under remarkable stress. The abrasive fibers contained in the composite can cause drilling, milling and grinding tools to wear extremely quickly, resulting in frequent tool changes. In the case of drilling, the hole quality determines when the tool needs to be changed or indexed. To counteract this heavy wear, high-quality tools made from polycrystalline diamond or tools with diamond-like coatings are generally used. The resulting tool costs can have a significant impact on the competitiveness of the pioneering material.”

An improvement in part quality and hole quality, in particular (as in the case of airframe manufacturing, where CFRP-titanium stackups are becoming popular), increased tool life and reduced secondary operations will generate a large gain in productivity through shorter lead times.

Capricorn says the introduction of wet machining processes has paid off. “Compared to dry machining, we were able to increase tool life by up to six times,” Mr. Lussi says. “This creates real savings potential. The processing time has also been reduced. Before using the coolant, we had to conduct several roughing and finishing operations in order to achieve optimal processing. Due to wet machining, we managed to reduce these operations to one roughing and one finishing operation.”

So why is dry machining of composites still common practice, if machining time, quality and tool life can be drastically improved through the use of cutting fluids? According to Ms. Demmerling, the main reason is the lack of appropriate research and testing to ensure that a wet machining process does not degrade the material’s mechanical properties.

Coolants Designed for Fiber-Reinforced Plastics

To realize the benefits of wet cutting, Rhenus Lub decided to develop coolants specifically for the sustainable machining of fiber-reinforced plastics.

“We have been testing the machining of CFRP with coolants for some time and joined forces with strong partners from the outset of the research project to generate synergies for this innovative project,” explains Dr. Hans Jürgen Schlindwein, Rhenus Lub’s head of R&D in coolants. “The company has been testing newly developed coolants in cooperation with the Research and Transfer Centre at the University of Applied Sciences Zwickau, which carries out sustainability tests in a production environment inspecting tools and workpieces for wear and machining quality. Rhenus Lub also works closely with the German Aerospace Centre (Deutschen Zentrum für Luft- und Raumfahrt, DLR) on material and compatibility testing.”

The first fully developed products are the special coolants, Rhenus XY 190 FC and Rhenus XT 46 FC. The former is a water-soluble, fully synthetic formula, specifically designed for CFRP and glass fiber reinforced plastics (GFRP). The Rhenus XT 46 FC is a water-miscible coolant that can also be used for composite or stacked workpieces made of aluminum, titanium alloys and steel.

According to Rhenus Lub, industrial tests show that using special coolants to machine CFRP and GFRP has a direct and positive impact on cut and hole quality, cost per hole, process costs and costs of waste, as well as on other key process expenses.

Industrial Field Tests Yield Positive Results

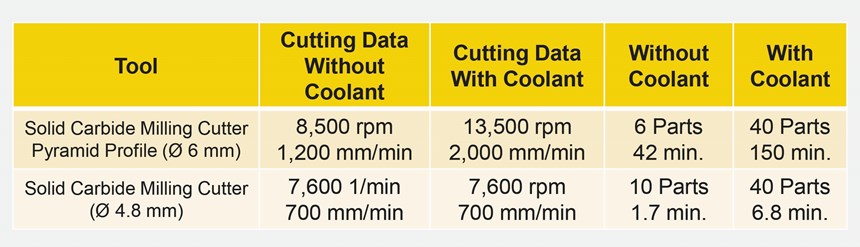

Industrial field test shows the advantages of CFRP machining with coolants over conventional dry machining (see Figure 1). Using coolants, tool life could be increased by as much as four times and feed rates could be as much as 60 percent higher than machining dry. “With their high degree of heat dissipation and excellent lubrication performance, the special coolants produce cutting data that would be inconceivable in dry machining,” Ms. Demmerling says.

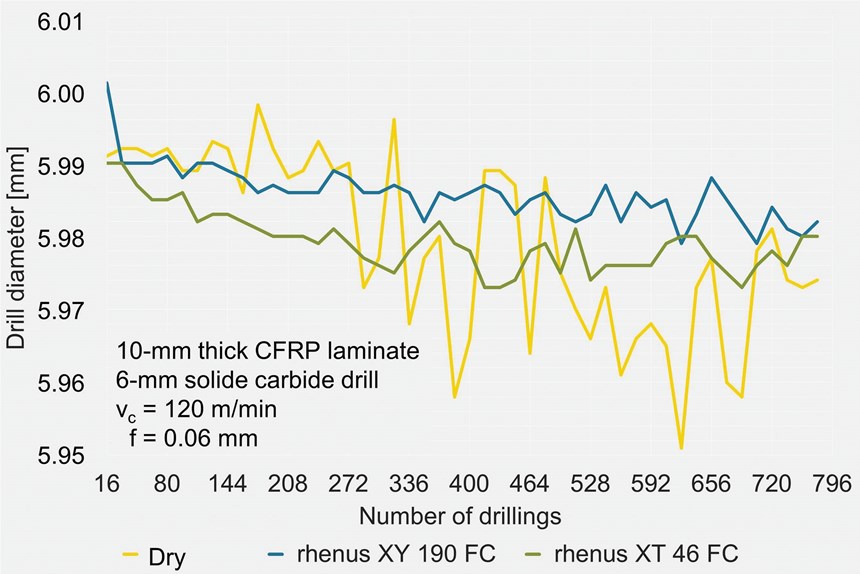

Machining and dimensional accuracy also improved through use of the coolants, as shown in Figure 2. Testing showed the coolants helped tools cut more accurately compared to dry machining and dimensional stability fell more frequently within the defined tolerance field.

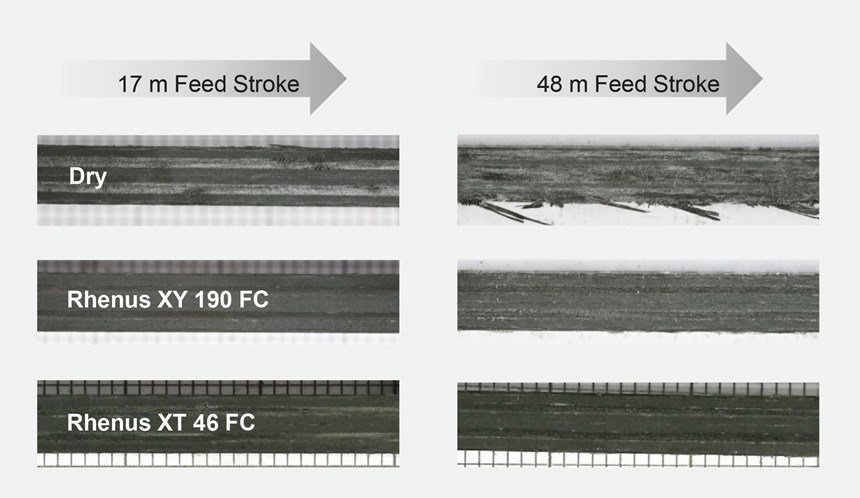

Rhenus Lub also conducted milling tests to show how surface quality improves through

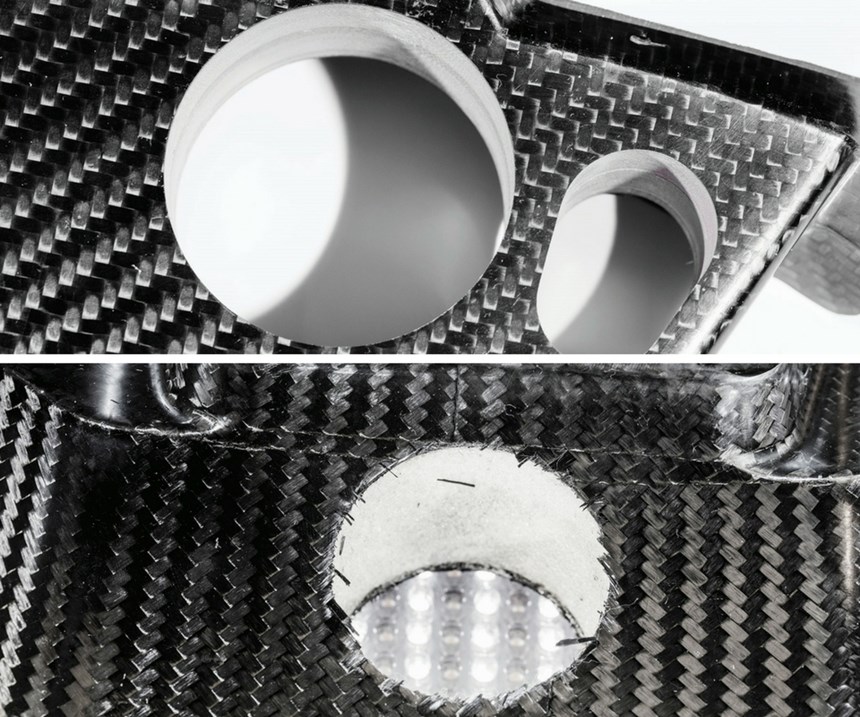

wet machining (see Figure 3). After a milling cutter feed stoke of 48 meters during dry machining, delamination occurs, while the Rhenus coolants helped avoid delamination and, as a result, expensive postprocessing operations.

Furthermore, the interactions between the coolants and the CFRP were studied in a series of tests carried out with the help of the German Aerospace Centre under what are considered worst-case conditions (storage of the CFRP for a week in the coolant at 60°C, tests ranging to -50°C). The result was positive, Ms. Demmerling says: “The short residence time to the coolant during machining will not change the material properties of the CFRP, and there were no signs of the coolant penetrating the composite material.”

For the Rhenus Lub team, it’s clear there will be no alternative to using coolants in composites machining in the future. “When it comes to economical machining of CFRP without posing risks to health or the sustainable competitiveness of these promising materials, we must accept that, in the long term, coolants are the only alternative,” Dr. Schlindwein concludes.

For Capricorn, too, there will no longer be an alternative to wet machining of many of their components. “The use of the coolant makes machining our hybrid materials significantly easier,” Mr. Lussi says. “In general, milling operations and drilling—without changing the feeds—present no problem for us.” However, he says the most important factor for Capricorn is component quality, and there were visible improvements in this regard, too. “The fibers are not as torn as they were before with dry machining,” he says.

Read Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More