Waterjet Is Key to Quick Response

With the versatility to perform basic machining operations in a variety of materials, waterjet technology helps this shop accelerate responsiveness and increase competitiveness.

Share

Relying on outside vendors can hamper a shop’s ability to respond quickly. At least, that was the experience of Pacific Machine Inc. When the Tacoma, Washington-based manufacturer realized it was spending too much time waiting for delivery of critical parts, it invested in waterjet technology to perform basic cutting operations in-house. The new equipment has enabled the company to cut a wide variety of materials and provide 24/7 service in a timely manner.

Founded more than a century ago, Pacific Machine performs machining, welding, forming, fabrication and assembly services, mostly in the repair and reengineering of manufacturing production components. Reverse-engineering worn or broken parts and producing replacements often involves updating a part’s design to improve performance. In some cases, the company also performs production runs. The facility handles a wide range of materials, from steels and irons to plastics, aluminum, heavy metals and rubber. Customers include food processors, transportation equipment manufacturers and makers of heavy machinery.

Jim Tschimerple, president and fourth-generation owner, says this wide range of materials often made it difficult to respond to customers in a timely manner. For instance, an assembly for a food-processing company involved milling, drilling and tapping a 0.5-inch-thick 304 stainless steel plate and attaching a plastic wear part. First, however, the shop had to contact a supplier that could cut the steel plate to the desired shape before delivering it for drilling and milling. Time was also lost specifying and ordering the plastic part and waiting for it to be produced and delivered. In a rush repair situation, the added time hampered Pacific Machine’s ability to quickly help a customer get a production line back in action.

Mr. Tschimperle researched a variety of potential solutions, including plasma, laser and oxyacetylene processing. Ultimately, he decided that abrasive waterjet cutting would be the best fit because it can precisely cut the wide range of materials and thicknesses the shop encounters. Also, CNC programming would enable quick adaptation of the process to small parts runs and complex shapes. Unlike cutting technologies that involve burning, waterjet cutting produces no slag that would require secondary processing for removal and does not generate similar airborne pollutants.

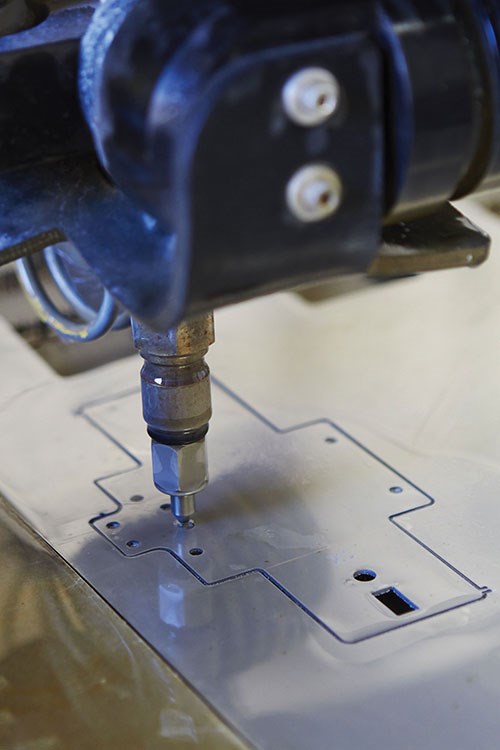

Pacific Machine acquired its first waterjet cutting machine about 3 years ago. In the case of the stainless steel food processing assembly, the shop can pull a 304 stainless plate from its own inventory and cut to the needed part shape. According to Mr. Tschimperle, the company could program, load and cut a part within 15 to 20 minutes using waterjet technology. The process is precise enough to generate holes to finished size without secondary drilling operations, he says. To finish the part, the company runs it through another machine to tap the threads in the hole. Stock for the plastic wear component can also be cut on the waterjet before conventional machining. “We get the job done fast, and we look like heroes to our customers because of our efficiency and speed, which in turn, makes them very happy,” he says.

As materials, processes and tolerances grew more demanding, Pacific Machine sought to upgrade its waterjet technology. Just over a year ago, the shop purchased an Omax 60120 JetMachining center. The Omax features a 5- by 10-foot table and accommodates workpieces ranging from 20 gage (0.020 inch) to 7 inches thick. The company also opted for Omax’s Tilt-A-Jet accessory, which provides taper compensation. Additionally, the machine’s Collision Sensing Terrain Follower detects changes in workpiece height and automatically adjusts Z-axis height to prevent collisions and maintain correct cutting standoff. This capability protects the machine’s mixing tube from damage in the event that a workpiece warps or pops up when being machined.

In addition to helping minimize its response time, waterjet helps the shop price services competitively. For example, the waterjet significantly reduces handling costs. “In our business, any time you touch a part, it costs you money. So the number of times we don’t have to touch it, deburr it, knock the slag off or whatever, it is a cost saving to our customers,” Mr. Tschimperle says. He adds that payback on the investment in the waterjet was really quick—about a year and a half—noting that 3 to 5 years is more typical for this kind of capital investment.

Waterjet cutting also expedites the shop’s repeat production jobs. One such project involves machining extensions for platforms used at the entry doors of wind generator turbines. This project requires cutting 244 parts to shape from aluminum plate and machining a number of bolt holes. The parts could be cut with laser or plasma, but they would require another step to clean up slag from the back of the part, Mr. Tschimperle says. “We can just take the parts off the waterjet table and put them into a sub-assembly,” he says.

With its 12 employees, the shop handles between 100 and 140 jobs per month. An engineer performs design and reengineering work using CAD software that dovetails with the waterjet machine’s Omax Intelli-Max software suite. Programming is performed both offline in the office and by the operator at the machine. One feature of the software the shop credits for boosting efficiency is a nesting program that arranges parts on a piece of stock to maximize material use and setup time. Different parts, or those from more than one customer, can be grouped for cutting on one piece of stock.

According to Mr. Tschimperle, the shop remains successful because it continually upgrades its services and manufacturing equipment to fulfill changing customer needs. “A key factor is our inability to say ‘no’ to our customers,” he says. The wide array of equipment—including the waterjet—as well as skilled people and processes, helps the company to continually find ways to say “yes.”

Related Content

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreHigh RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More