Vision-Guided Cobot Doubles Daily Production

Walt Machine Inc. needed to meet a short-term rise in production volume. A Universal Robot UR10 with a Robotiq wrist camera and a two-finger 140 gripper enabled lights-out production and reassignment of current staff.

Share

With the promise of “quality parts, made to print, delivered on time,” Walt Machine of Lumberton, Mississippi, prides itself on its reliability, but it struggled in the face of a potential bottleneck. Every year, the company uses a single CNC machine to produce thousands of camera housings in just two months’ time. This short-term rise in production volume regularly strains its ability to fulfill the promise of its motto. To face this challenge, the company invested in a simple vision system from Robotiq of Lévis, Quebec, Canada, and installed it on a collaborative robot (cobot) with a gripper system from Universal Robots (East Setauket, New York).

Specializing in high-precision optical work for scientific camera assemblies, Walt Machine receives an order each spring for about 6,000 camera housings that it produces on its Haas VM-3. The size of this order might suggest that company President Tommy Caughey should hire a full-time CNC operator in addition to his regular staff, but this solution has its flaws. To start, it takes 30 to 45 minutes to machine one side of each camera housing. This means that, working eight hours a day, it takes several weeks to produce the full order with a single machine. In that timeframe, the parts would be almost ready for delivery by the time a new employee could be fully trained.

Rather than invest in training an employee and worry about that person’s retention between production rushes, Mr. Caughey considered a robotic solution. “I saw Universal Robots at the International Manufacturing Technology Show (IMTS) maybe four or six years ago, and I found it interesting: a robot that does not require any extra stuff. I followed up throughout the years and thought that’s where we needed to go one day,” he says. A hurdle to this solution was that the cobot would need either a vision or a conveyor system to pick up raw parts from the VMC’s table. Mr. Caughey was advised that this was a very difficult process, one that a dedicated “vision expert” should handle.

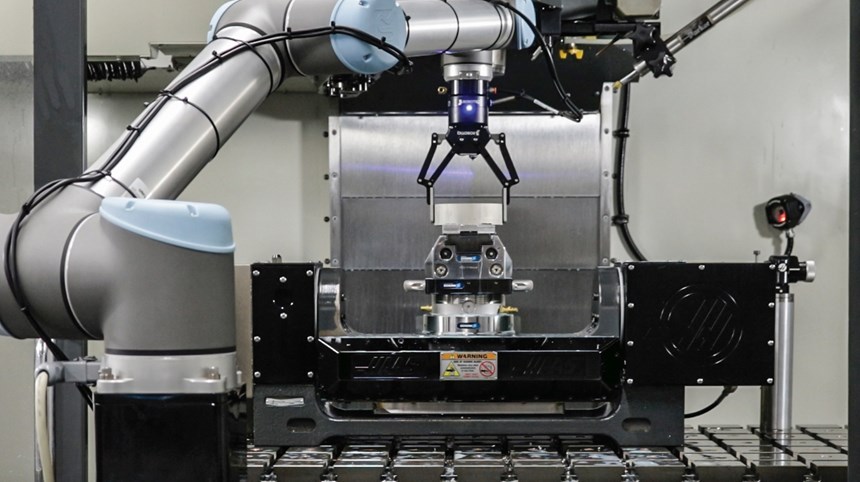

However, in June 2016, Robotiq released the Plug + Play wrist camera exclusively for Universal Robots. This system allowed Mr. Caughey to check every box on his wish list. He purchased a UR10 cobot and mounted the wrist camera directly above its two-finger 140 gripper, enabling visual scanning with simplified robotic programming.

To teach the cobot, Mr. Caughey says, “either you take your part and set it on the surface where you want to pick it, and you take four snapshots of it in four different orientations, or, if it’s something simple like a rectangular or circular blank, you just set the dimensions of what you are picking, and (the cobot) knows.” These simple techniques enable the cobot to be taught in about 10 minutes, he says, making a vision expert unnecessary.

The next step is to place 15 to 20 of the same unmachined parts on a table within the cobot’s field of view. The robot rotates over the table and takes a snapshot of the parts with the camera, then moves closer and takes a more detailed picture of a single part. After identifying the workpiece, the robot moves it into the CNC machine’s vise and sends a signal to the machine tool to start.

Arthur works overnight, enabling the shop to machine twice as many parts every day.

Since Walt Machine purchased its cobot (which employees named “Arthur”), productivity in the shop has greatly improved. Although the cobot doesn’t directly improve cycle time, it does decrease the amount of time it takes to complete a job. Arthur works overnight, enabling the shop to machine twice as many parts every day. The company has decreased machine idle time, and Arthur has freed up staff time spent placing workpieces. This delights Mr. Caughey, who says he had been nervous about leaving a robot to its own devices all night. “It’s just about letting it go and accepting the fact that it’s going to run for an extra four to six hours,” he says. “You’re going to go home and nothing’s going to break.”

Employees’ time now can be put to better use. Machinist Matthew Niemeyer learned how to program the cobot, allowing him to improve his professional skillset on the production floor. “You’re still doing all the fine-tuning of it, such as the programming,” he explains, “but the remedial tasks of loading and unloading the machine is taken care of for you, so you don’t get worn out.” As the cobot took over these remedial tasks, Mr. Niemeyer stepped into a new role as sales representative, enabling him to put his talents to work drawing new business to Walt Machine. “We can get more business into the shop, which will lead to more machines, more robots and overall growth.”

All of this wouldn’t be possible without this first robot, Mr. Caughey says, and he believes that, in 10 years, every small shop like his will have at least one. Arthur can help Walt Machine successfully complete its annual 6,000-piece order, and it can do this without Mr. Caughey having to worry about how he would afford the costs of extra salary or training. The cobot has enabled the staff at Walt Machine to improve their skills while growing the business.

Related Content

3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read More4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More