Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

I had the chance to work with TechSolve, the machining consulting firm based in Cincinnati, Ohio, on filming some really ugly machining passes.

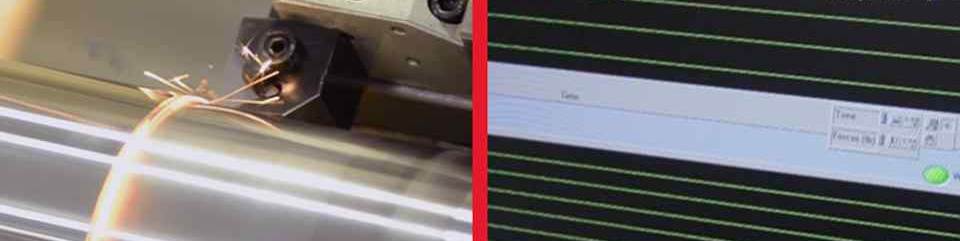

The point was cutting force analysis. Watching poorly performing cuts while also seeing the corresponding cutting force profiles illustrates what force measurement can reveal about the process. In many cases, force monitoring is limited to the machine’s spindle-load monitor, but TechSolve can bring more than this. It can measure forces more specifically and directly using a three-component dynamometer.

Force analysis can be useful for diagnosing the challenges of an application involving a difficult workpiece material and/or an unstable process. To the knowledgeable observer, force profiles can reveal the problem areas in a process—the shortcomings to address to make the process consistent and reliable enough for unattended machining.

In this video of machining 4140 steel, watch the cuts and see the force profiles corresponding to (1) gradual tool failure, (2) cutting with a rake angle that is too highly positive for the process and (3) the development of a built-up edge.

Related Content

-

Briquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.

-

Selecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

-

The Impact of Cutting Teeth Spacing on Machining Stability

Many cutter designs are available, and variable teeth spacing (or variable pitch) cutters can be used to influence milling stability. Let’s discuss why teeth spacing affects stability.