Vibratory Finishing System Handles Delicate Die Castings

Kovolis Hedvikov A.S. needed a flexible finishing process integrated into its existing production scheme. Rosler's continuous-feed vibratory system provided efficient finishing of large, delicate die castings.

Share

Kovolis Hedvikov was founded in 1816 as an ironworking operation. Since 1945, the company, located in Temošnice, Czech Republic, has focused solely on aluminum die casting, primarily for the automotive industry.

Kovolis produces components from nine different aluminum alloys ranging in weight from 7 ounces to 18 pounds via vacuum-investment casting and rheocasting. These components are produced for automotive OEMs and Tier-One suppliers for braking systems, power steering systems, turbo chargers and air-conditioning compressors. In addition to die casting, Kovolis provides machining, heat treatment and surface finishing services.

Recently, the company decided to replace its vibratory finishing system to better accommodate the different types of parts its customers were requesting. “Our product portfolio underwent a drastic change in the past years,” says Jiri Buzek, manager of Kovolis’ Foundry III. “The trend is going to larger and more delicate components, which require a vibratory finishing step after punch deburring. Our existing finishing system was not designed for this and had also reached the end of its productive service life.”

The new finishing system had to not only cope with larger workpieces, but also provide a gentler finishing process while maintaining high uptime and cost efficiency. In addition, it had to integrate into Kovolis’ current manufacturing process and fit within the available floor space, using an existing workpiece-loading device and hot-air belt drier.

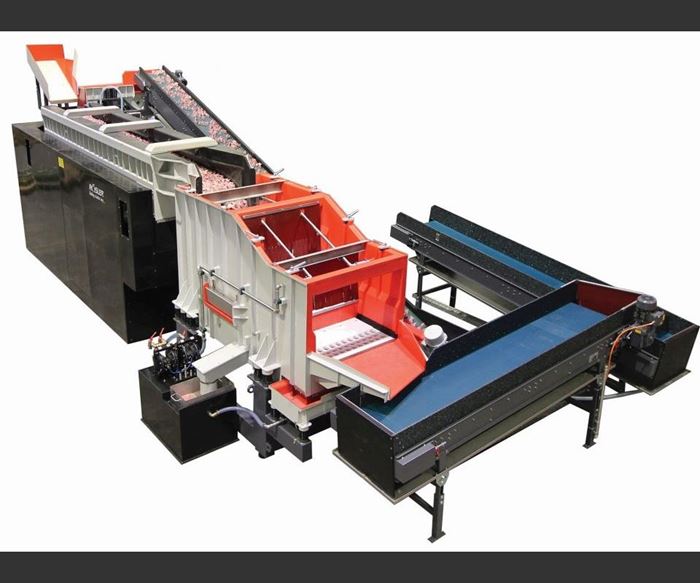

Kovolis planning engineers decided to purchase a continuous-feed vibratory finishing system from Rosler, a German manufacturer of shot blasting and vibratory finishing equipment and consumables. “We decided to go with the Rosler system because it offers ample capacity, and Rosler met all our special technical requirements,” Mr. Buzek says. It was also important that Rosler could supply all the necessary finishing compounds and media.

The finishing system includes a Rosler R 550/4600 DA linear, continuous-feed machine with a usable length of 15 feet. The functions of the company’s existing workpiece loader and hot-air belt drier were integrated into the finishing system’s control. Kovolis uses this system to finish approximately 30 different workpieces with maximum diameters of 12 inches. That said, because the system can handle parts with diameters ranging to 16 inches, it offers the flexibility to accommodate larger components in the future. In addition, a different automatic workpiece loader can be easily integrated, should the company decide to do so.

Finishing cycle times range from 30 to 60 seconds, depending on the workpiece design. The system’s process channel features a single, U-shaped cross section to facilitate the movement of workpiece and media through the finishing machine. The RKM plastic media used is said to produce quality finishing results within a maximum processing time of eight minutes. Processing time can be adjusted by simply increasing the inclination of the machine’s processing bowl. Compared to systems with a separate vibratory discharge channel, this system is designed to move workpieces through the machine at a constant speed, preventing jams that could nick or deform the workpieces.

To prevent workpiece damage during the separation cycle, a multi-deck, vibratory screening unit with two steps and minimal drop heights is used. The undersized-media classification system is equipped with an adjustable bar screen to enable Kovolis to specify the dimensions of undersized media that are to be discharged. Because the finished die castings do not require a separate cleaning procedure for the removal of media fines from their surfaces, the separation unit is equipped with a spray-rinse station. After the workpieces have passed through the hot-air belt drier, they are delivered to packaging or machining.

In addition to the R 550/4600 DA, Kovolis purchased a Z 1000 automated centrifuge to clean the process water used by this new machine as well as the company’s existing rotary vibratory equipment. This unit offers a centrifugal force ranging to 2,000 G and removes solid particles larger than 2 microns from the process water. Sludge that can weigh as much as 66 pounds is automatically discharged from the rotating drum.

Unlike centrifugal systems that use a peeling knife that constantly rotates with the drum, the Z 1000 is equipped with a stationary peeling knife. During the peeling cycle, the knife moves via pneumatics to the inner wall of the slowly rotating drum and removes the sludge without placing any additional load on drum bearings. Upon completion of the peeling cycle, the inside of the drum is cleaned by a spray rinse system to prevent additional sludge deposits that could cause an imbalance resulting in premature wear of the drum bearings during subsequent peeling cycles.

“In the past, we cleaned our process water chemically or with a semi-automatic centrifuge,” Mr. Buzek explains. “This was highly labor intensive and costly. With respect to process-water cleaning, Rosler provided us again with the optimum solution. We are certain that with the new equipment, we will not only improve the quality of our finishing operation but, at the same time, will become more cost efficient.”

Related Content

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreInside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreWhere Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)