Share

Artificial intelligence (AI) is poised to make industrial equipment predictive maintenance truly predictive.

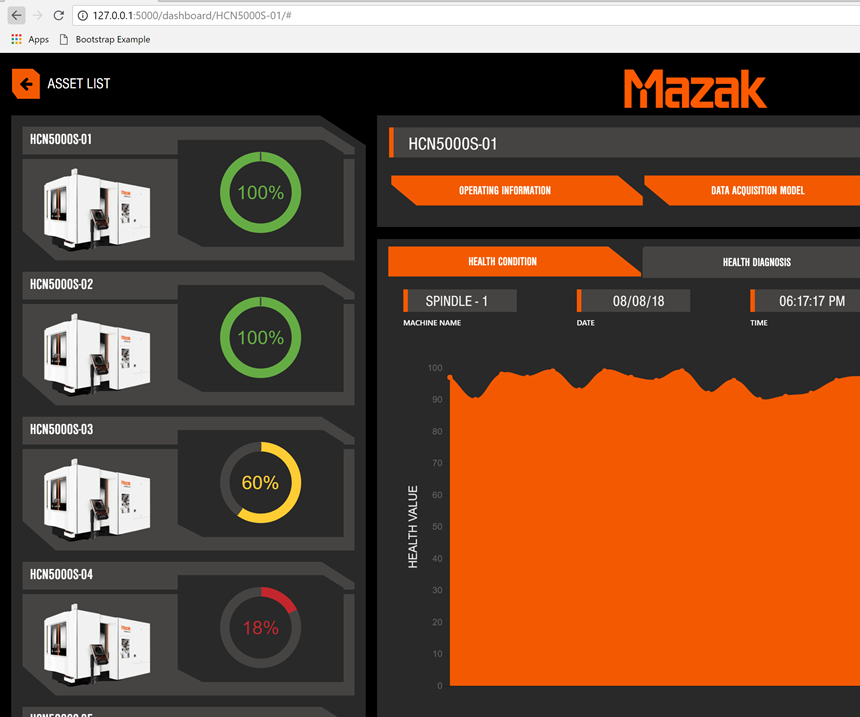

One example I wrote about last year was Cosen Saws’ cloud-based predictive maintenance app that not only monitors blade life for the company’s CNC saws, but also predicts blade failure well before failure is immenent. A similar example is Mazak’s AI-based Spindle Health Monitoring System (SHMS) that is currently an option for its HCN horizontal machining centers (HMCs).

Both systems were developed in conjunction with the University of Cincinnati’s Industrial AI Center (formerly the Center for Intelligent Maintenance Systems). Dr. Jay Lee, founder and director, researches prognostics and health management with an eye toward ensuring zero-breakdown performance for industrial equipment.

Today, the Industrial AI Center is a National Science Foundation industry/university collaborative that consists of the University of Cincinnati (UC), the University of Michigan and the Missouri University of Science and Technology. Since 2001, the center has conducted more than 100 projects in partnership with more than 100 international organizations, including Toyota, Boeing, Bosch, Caterpillar, GE Aviation, Goodyear, Harley-Davidson and Siemens. Its goal is to eliminate the risk of unexpected industrial equipment breakdowns.

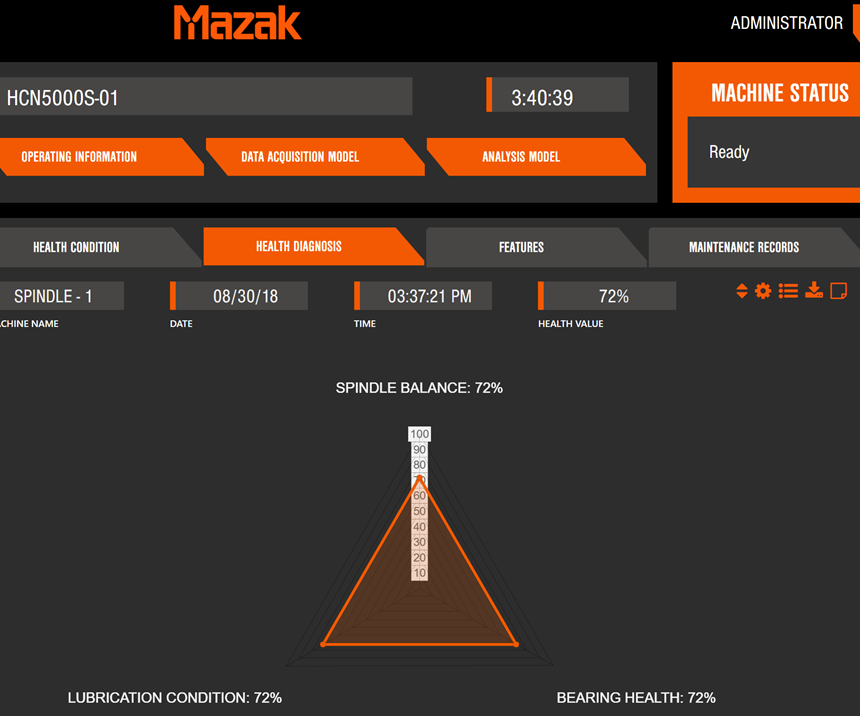

Mazak’s SHMS was created to enable shops to take spindle maintenance measures long before spindle or spindle bearing damage occurs, minimizing downtime and enabling any maintenance tasks to be more conveniently scheduled. Joe Sanders, process development coordinator for Mazak, says the key difference between the company’s AI-based system and other spindle monitoring technology is that the SHMS is not based on threshold data. That would be the case in which an alert would be sent when a specific spindle vibration frequency is detected that would suggest damage has already or is very soon to occur. Instead, he says the SHMS can detect issues months before they happen, providing time to schedule spindle repair or replacement at the most convenient time.

Data crunched from one year of extensive spindle destructive tests led to the creation of the SHMS’s AI spindle neural network self-organizing maps, spindle-specific signatures that can determine the difference between good vibrations and bad ones. Algorithms created from these maps predict how spindles will degrade over time (barring a crash) while displaying remaining lifespan as a percentage. “This differs from estimating a timeline of a spindle’s life, because we don’t know if a machine will be used for light-duty work, heaving cutting, 24/7 operation or any other possible scenarios,” Mr. Sanders explains.

The SHMS’s primary components include vibration and current sensors, a data acquisition module, and an industrial computer to process the SHMS algorithm. Upon installation, a one-hour modeling test maps that particular spindle’s operating signature. After that, users can perform periodic 60-second tests that compare data to the spindle model. When cycle times are sufficiently long, Mr. Sanders suggests performing a test after each part is completed. However, this likely is not necessary for parts with relatively short cycle times, he notes.

The SHMS is available as an option on Mazak HCN machines equipped with the the company’s Smooth CNC and as a retrofit for those machines with Matrix CNCs. (The system’s graphical user interface is currently being refined.)

The company soon plans to offer ballscrew predictive monitoring as part of the SHMS option, too. In fact, the Industrial AI Center has been gathering data to develop predictive wear algorithms for ballscrews for some time. The next goal is to create an active SHMS technology that will continuously monitor spindle health and eliminate the need for 60-second tests. This active system also will be able to detect tool wear and automatically reduce cutting parameters to prevent breakage, Mr. Sanders says.

Displayed at the International Manufacturing Technology Show (IMTS) last September, SHMS will be officially introduced at the company’s Discover event in October at its Florence, Kentucky, headquarters.

Related Content

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read More3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

Read MoreFour-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)