Updated Workholding Improves Turning Performance And Speed

Many shops maintain old workholding on their lathes, and there is a loss of opportunity to increase productivity and repeatability. Workholding tends to be an afterthought. In reality, workholding can increase performance a great deal.

Share

Many shops maintain old workholding on their lathes, and there is a loss of opportunity to increase productivity and repeatability. Workholding tends to be an afterthought. In reality, workholding can increase performance a great deal. Dana (Magog, Quebec), one of the world’s largest suppliers to vehicular manufacturers, recently rethought its existing workholding when it redesigned its SPL yoke. Located within the universal joint of the drive shaft, Dana’s SPL yoke helps to increase the life of a vehicle’s driveshaft to 500,000 miles. Dana currently produces 2,000 yokes per week. Later this year, at full production, the company expects to produce 5,000 weekly.

Given the irregular shape of its workpiece, Dana engineers found it difficult to form a completely secure grip. Previously, the manufacturer had been using an oversized four-jaw chuck that relied on fixtures for centering the workpiece on the second axis after the initial set of jaws had gripped. Along with limited turning speeds, Dana had to accept the tolerances based on the old fixturing.

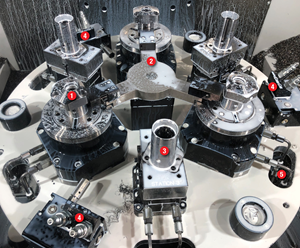

“(To review workholding options) I searched the Internet,” explains Eric Fortier, process engineer, Dana Canada Inc. Some of the information he found was from Kitagawa (Schaumburg, Illinois). “I followed Kitagawa’s Chuck Selection Guide and then called to speak with a Kitagawa engineer. He agreed I should use a four-jaw chuck.” Kitagawa’s HW Series and its 2 + 2 jaw configuration is recommended especially for use with irregularly shaped workpieces. The HW Series chuck can position, or center, a part on two axes.

Dana decreased cycle times from 50 to 35 seconds per part, increased turning speeds and improved repeatability with the incorporation of Kitagawa/NorthTech Workholding Inc.’s HW-10 two-stage, four-jaw power chuck.

The HW Series’ configuration, where two pairs of two jaws self center independent of one another, translates into tighter tolerances and greater repeatability. In the case of Dana, the first set of jaws is non-gripping. These jaws eliminate five degrees of freedom as centering pins are positioned into two shaft holes that were machined in a previous operation. At maximum stroke, they allow 0.002 inch to 0.003 inch of clearance (on the ear width). The second set of opposing jaws employs carbide grippers to grip the rough forging between the connection ears and to self-center the part radially, eliminating the sixth and final degree of freedom.

For Dana, one chuck and a base jaw setup have been designed to hold three different drive shaft yokes. The base jaw moves along the serrations, and the top jaws are changed out. V-blocks facilitate the loading of the 15- to 25-pound forgings. These blocks match the positioning tooling used in the original machining of the drive shaft holes. Along with machining the lead into the holes, the V-blocks allow the non-gripping pins to accurately engage and position the forging. After the forging has been machined, the pins disengage. To accomplish this, Kitagawa engineers designed a part retainer to slip between the ears of the forging and prevent it from walking or sticking to the pins as they retract. This part retainer is adjustable to accommodate all three forgings.

What’s more, the HW weighs less than Dana's former workholding, contributing to a faster ramp up speed for the manufacturer. “Because the stroke needed per jaw (8 mm) was longer than standard, Kitagawa suggested a special hydraulic cylinder,” says Mr. Fortier. Kitagawa engineers recommended a two-stage independent cylinder for Dana’s application.

“Using this cylinder, one piston controls one set of jaws, while a second piston operates the other set. Since each piston operates off of a separate hydraulic line, we were able to sequence them through a timer. This ensures that the non-gripping jaws are fully engaged (and that the part is properly positioned) before the gripping jaws begin to grip the casting,” says Tim Winard, Kitagawa/NorthTech Workholding, Inc. engineering manager.

Related Content

Prioritizing Workholding Density Versus Simplicity

Determining whether to use high-density fixtures or to simplify workholding requires a deeper look into the details of your parts and processes.

Read MoreUsing Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

Read MoreMachining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

Read MoreNavigating Large-Scale CNC Machining: Suburban Tool’s Niche Strategy to Stay Competitive

Facing increasing competition from lower-cost imports, Suburban Tool made a move toward large-scale, in-house machining. By identifying a niche in large, precision angle plates and tombstones, the company has strengthened its ability to control quality and protect its reputation.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;width=860)