Up To 12 Tools In One Holder

Imagine a single cutting toolholder that can be used to perform 12 distinct metalcutting operations without a tool change. That's the concept behind a new cutting tool innovation designed and built by Mazak.

Share

Imagine a single cutting toolholder that can be used to perform 12 distinct metalcutting operations without a tool change. That's the concept behind a new cutting tool innovation designed and built by Mazak (Florence, Kentucky).

It's called Flash Tool holder, and it is designed to complement the capabilities of the company's multitasking Integrex series of machine tools. Integrex is a turning center-based machine that uses a swivel milling head to perform fixed tool operations while rotating the workpiece or rotary tool operations with the workpiece stationary. It can also do C-axis contouring by rotating the part and milling cutter simultaneously.

The process advantage of the Integrex machine is its ability to completely machine complex workpieces in a single handling. It uses a synchronized main spindle and subspindle to present all workpiece features for first and second operations to the swivel milling head.

Like any tool changing machine, such as a machining center or turning center, reducing tool changes is an efficient method of optimizing cycle times. An example on machining centers is using combination tools that perform drilling and tapping in one cutter to help increase spindle utilization. Rather than change tools, one cutter does two or more operations. Over a medium part run, the time savings from reduced tool changes can be significant.

Likewise, reducing the number of turret indexes on a turning center ups the time in the cut. If the same cutting tool can be used to rough face and rough turn, the time savings from reducing turret indexes add up over the run of parts.

Mazak designed the Flash Tool holder to combine up to 12 cutting operations in a single holder. It's important to note that this tool will not work without the rotary and swivel positioning capabilities of the Integrex milling head. They are a system.

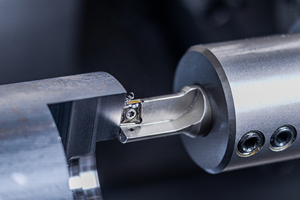

The standard Flash Tool holder uses a four-flute shank. The key to this cutter is that each insert in each flute is different. Each insert is clamped in a pre-milled pocket in the toolholder. For rotary operations including milling, chamfering and drilling, the outside inserts do the cutting. They are located on the nominal or major OD. Other inserts with different nominal OD are used to perform rough and finish turning, threading and ID work.

It's the milling head that is able to bring these inserts accurately to bear on the workpiece by changing the effective geometry of the insert. On turning operations, changing the angle of inclination of a given insert by swiveling the B-axis allows more or less of the insert edge to be engaged in the cut. A wide edge can be used for roughing, or a single point can be used for threading. The milling head indexes and locks in 24 positions in 15-degree increments.

Depending on the application, and its tooling requirements, the Flash Tool concept can be used to carry a large variety of inserts. Besides the standard four, tool holders can be used that have two, three or six different inserts.

Flash Tool holding is an interesting innovation that makes an individual multi-flute cutter into a veritable tool storage unit. It represents a tooling strategy that would be impossible without the advances in multitasking machine tools.

Related Content

Ceratizit's Updated Tooling Solutions Improve Machining Performance

The company has upgraded its EcoCut indexable inserts lineup, as well as introduced two new toolholding and workholding solutions.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreRego-Fix Toolholding System Reduces Coolant Consumption

MQL PG collets are designed for machines using one-channel, internal through-spindle MQL systems.

Read MoreJergens Pull Studs Enable Quick Changeovers

SP140 and K02 pull studs offer quick-change solutions for vise or gripper jaws, electronic component manufacturing, packaging machines, medical technology and automation.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=300;quality=90)