Trunnion Table Helps VMC Fill Utility Role for Shop

Learn how a trunnion table brought horizontal versatility to a vertical machining center for custom pump production at Vertiflo Pump.

Share

A machine tool’s versatility is a valuable asset for specialty machine shops. One option to improve upon a machine’s capabilities is to add a trunnion table. When industrial pump specialist Vertiflo Pump Co. of Cincinnati, Ohio, purchased a new vertical machining center, it used a trunnion table from TrunnionTable.com (Elsmere, Kentucky) on the machine’s fourth axis to handle parts previously machined on a horizontal.

“Purchasing the vertical machine with the trunnion table saved us between $50,000 and $60,000 on new machine costs alone,” says Phil Eldridge, operations manager at Vertiflo. “On top of that, we’ve cut per-part cycle times in half while freeing our operators to handle more than one machine.”

Vertiflo Pump Co., a privately owned company, has served the industrial pump market since 1980. Its namesake vertical, horizontal and self-priming pumps are used in a variety of process control applications for everything from agriculture to wastewater treatment. The company manufactures, assembles and ships hundreds of pumps every month, ready to pipe up. Pumps are primarily made of cast iron and 316 stainless steel, and the verticals range from 2- to 25-feet long and weigh as much as 3,000 pounds. The castings are sourced from domestic foundries to help shorten delivery times.

“Every order is considered custom,” Mr. Eldridge says. “Typically, the variables include conditions of service, materials, pump length and size, drivers, plates, and discharge sizes. There are a lot of common parts, but each pump has custom aspects based on the application.”

In order to create a more versatile machine lineup, the industrial pump manufacturer purchased a new EC 1600 horizontal machining center to join two smaller Mazak verticals. To complement the EC1600, the company initially investigated purchasing a smaller HMC, because many of the parts it manufactures require a horizontal orientation and are too small for the larger machine, Mr. Eldridge says.

After talking with a sales engineer, the company decided to acquire a mid-sized Haas VF5 vertical machining center. The Haas VMC would provide more flexibility, fit nicely with the two smaller verticals and large horizontal, and could be equipped with a table from TrunnionTables.com, Mr. Eldridge says.

“We realized we could go with the large, four-axis capability on the EC 1600, get the mid-sized vertical with a trunnion table and have all our bases covered while saving a lot of money,” he says.

While the company holds some pump assemblies and nearly all common parts in inventory, pump orders generally originate with customers selecting a pump on the company’s website. The company’s “B.O.B.” software system enables its customers to select their pump design and sizes online, and its in-house Configurator software then creates a bill of material. From this, the company makes the parts, assembles the pump and ships it.

The trunnion table has enabled the company to optimize this process. Typically industry turnaround times are anywhere from six to eight weeks, but Vertiflo can turn the finished pump around and ship it in one to three weeks, Mr. Eldridge says.

“Those orders account for about 85 percent of our business, so productivity is a must, and we’ve got it with the trunnion table,” he says.

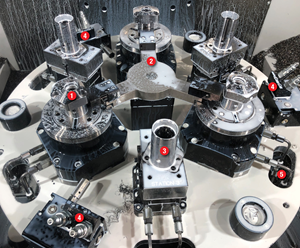

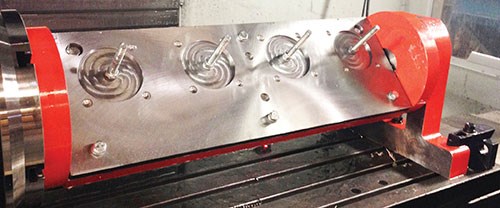

Machine shop supervisor Ron Davenport credits the trunnion table for boosting the shop’s productivity in a couple of ways. According to Mr. Davenport, parts that require milling and drilling at 90 degrees now can be machined in one setup instead of multiple setups. The benefit of this is that the company can now machine as many as four parts at once with a 40-minute cycle time. Prior to acquiring the trunnion table, the one-part cycle time was about 20 minutes, Mr. Davenport says.

“Now, we’re getting more parts in less time. Plus, the longer cycle time allows us to operate multiple machines at the same time, so we’ve also lowered manpower costs,” he says.

Mr. Davenport likes the flexibility he has in setting up different part families using fixtures he created in-house in conjunction with the trunnion table, as well as the table’s ease-of-use. “I made a couple of sub-plates that mount directly to the holes in the trunnion table, so we can set up six different part configurations,” he says. This includes multiple part types with similar bases. “The trunnion tables square themselves up almost automatically. It’s really easy to set them up and they’re very solid and well-built.”

The new VMC trunnion table has enabled Vertiflo to “right-size” its operations—meaning it can process parts on more appropriately sized machines, thus extending the life of its machine tool assets. Mr. Eldridge says Vertiflo was able to take a lot of parts off the EC 1600 that were just too small for it. Conversely, it was also able to take parts off the smaller vertical machines that were almost too big and that pushed them to the edge of their capacity.

Now, the small verticals can process more size-appropriate parts, which will extend the life of those machines, Mr. Eldridge says, and the company is getting the most out of its large-part machine by actually machining large parts.

“We feel we have the right machines processing the right parts, and it was all made possible by a $3,650 trunnion table.”

Related Content

Custom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

Read MorePrioritizing Workholding Density Versus Simplicity

Determining whether to use high-density fixtures or to simplify workholding requires a deeper look into the details of your parts and processes.

Read MoreUsing Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

Read MoreMachining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)