Trial by Fire

Founded in 1976, Taurus Tool & Engineering started as a multi-step cutting tool manufacturer, and always had a good reputation for quality tools. It started with two partners and a team of skilled employees, ultimately growing its Schaumburg, Illinois, shop to 17,500 square feet.

Share

Founded in 1976, Taurus Tool & Engineering started as a multi-step cutting tool manufacturer, and always had a good reputation for quality tools. It started with two partners and a team of skilled employees, ultimately growing its Schaumburg, Illinois, shop to 17,500 square feet.

Over the years, manual equipment was slowly removed and replaced with new, quicker and more accurate CNC equipment. The business flourished as Taurus became known for accurately engineered, precision manufactured cutting tools.

But in 2014, the upgrade program was accelerated dramatically.

In June of that year, the shop burned down. Losing most of its CNC machines, fixtures, and other tools forced Taurus to rebuild quickly or lose the business. Within weeks, Taurus acquired a larger, modern 25,000 square-foot facility in Batavia, Illinois, that could handle the growth that the business had been starting to see. After the fire, during rebuilding, Taurus was down for about three months. It scrambled to serve customers.

In February of 2015, the company was purchased in whole by employees Jim Kantak, president, Roger Wise, engineering manager, and Richard Thiele, production manager all of whom had long histories with the company. The company has more than 30 employees today.

In the previous 20 years, Taurus had become known for its engineering capabilities. Problem resolution at the spindle has been instrumental in the company’s growth. Backing this with superior manufacturing processes and a high level of quality control, Taurus became an industry leader in solid round specialty cutting tools. Tool size range 1/8 to 3 inches in diameter using HSS and carbide.

Setting goals

“We were already working toward becoming the number one round cutting tool manufacturer in the country and the key to that is, first, producing high performance tooling for our customers’ applications. Next is to do it consistently. Order after order. Last is the production end – how quickly and efficiently can you make the tools,” Mr. Thiele says.

The fire turned out to provide Taurus an unusual opportunity to put into place all the practices they had been thinking of and planning for in order to bring the company to the level of performance they wanted to reach.

“We began filling our new facility with some of the best technology on the market in a manner that would improve workflow, reduce production costs, and promote batch manufacturing capability and tool quality,” Mr. Kantak says.

“We are building on the past at Taurus by providing a service to our customers. We help them with their most troublesome tools and make the tools perform well. We consult and then redesign or optimize the design to address the pain points of our customers. We focus on engineering in our sales activity, earning customer confidence, showing how we respond to the tough assignment.

“Our biggest success is when our engineering solves problems for our customers who often have reduced their own staff of tool engineers. Today, they rely on the tool manufacturer to help them with their process—tool design, workholding, coolants and materials.

“We produce a sample lot of three or more pieces for our customers to try and prove the process tool runout, pressures, feeds and speeds. Today, we work with aerospace, automotive hydraulics, and off-highway customers.”

Recovering from the Fire

Mr. Kantak recalled, “ANCA and its local rep Metalworking Technologies Ltd, had been calling on Taurus for many years – we even uncovered a quote from ANCA dated the mid-90s that was never acted on. Finally, we went to ANCA in Michigan and worked with the machines and software and we liked what we saw.

“Pre-fire we had purchased two ANCA FastGrind CNC tool grinders – our company’s biggest machine acquisition in years. The initial reason was that we wanted to integrate the tool production machines with the server where we could save all the programs in one place rather than on 16 different machines locally. It would be whole different way of processing the tools.”

Mr. Theile says, “We knew what we wanted to accomplish and we were already were looking to order more ANCAs before the fire. We wanted to remove the old bad habits we thought we had and we had a plan in place to do just that.”

Previously, Taurus had run other brand CNC tool grinders, which were lost in the fire.

“It has been very interesting coming from a different machine tool builder’s machines and methods,” Mr. Theile stated. “We ran a different brand CNC grinder for 15 years and our operators, designers and machinists were used to producing tools according to those protocols.”

Once the move began, it was all-ANCA. “We moved in the FastGrinds and shortly thereafter four more ANCAs came in the door of our new location,” Mr. Kantak says.

“We looked at shop work flow. In the old facility, we were spread out and machines were placed wherever we had space. In the new building we made all the physical changes we always wanted in order to make the work flow through the shop more efficient, from material in the door, pre-processing the tool material, grinding on the ANCAs, inspection and shipping.”

Goal: Fresh Tool Design Thinking for Better Tool Performance

“It was a struggle for about six months after we moved into the new shop full of ANCAs,” Mr. Theile says. “Our people had to learn a new process for making tools. The old ‘gold standard’ did not apply. I told them, ‘Forget about the previous way. Instead, imagine what would be the craziest design, surface finish, and geometry to make the optimum tool for the customer’s job.’”

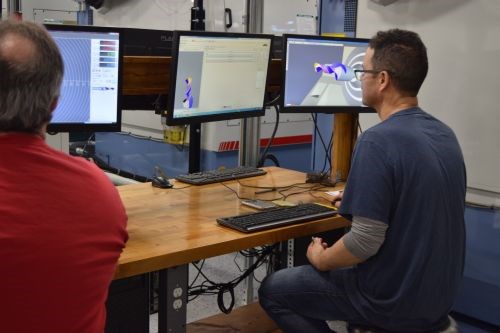

Taurus set up what it calls its Simulation Station on the shop floor – four seats in the middle of the action that operators can sit down to any time. Mr. Theile calls it the manufacturer’s water cooler. “We want the Station to be the center of interaction among the ANCA operators and tool designers. We feel that putting the design seats near to each other and on the manufacturing floor, we will get the kind of sharing and conversation that results in the best tool designs we can possibly make,” Mr. Theile says. Two other ANCA Cimulator3D seats are in the front office.

“We felt we needed to think outside the old box we had. So one way we wanted to do that is to get our people together at the Simulator Station, around each other, communicating on it. We know this is opposite of the old manufacturing foreman style.”

CIMulator3D simulates the programmed tool path exactly as it would be ground on the machine. New tool programs can be verified for size, shape, machine clearance and even cycle time estimates. CIMulator3D maintains continuous work flow through the machine by reducing development time and trial grinding.

“With the ANCA Cimulator we create a solid model of our tool designs and optimize them in the design phase before we put the material in the grinder,” Mr. Theile says. “This works to our advantage in tool cost because we don’t use the CNC grinder to try tools. We feel that with the Cimulator, about 70 percent of the first tools we grind are shippable product. Before, it was slim to none because the tweaking was done on machine.”

Goal: Save All Programs in One Place, Eliminate Paper

Taurus wanted to get away from the former practice of specific machines assigned to produce certain tools. It created bottlenecks. Machine flexibility, versatility, and storing all tool programs in one location was a key step to removing this issue from the shop floor.

The company now can ensure that tool production programs are highly repeatable by saving programs in one place. “We also wanted to cross-train employees. A number of them had become specialists in certain tools and we wanted to run all different types of tooling throughout the shop.

“The older machines made it difficult to save programs without upgrading. We had to run certain types of tools on certain machine with certain wheel packs for those type tools. This was a massive quality concern when we had 16 machines and all the tool programs were saved locally. Different operators ran tools and different feeds and speeds, with different wheels.

“As this industry evolves, a couple microns in surface finish matters to the tool performance. If I am cutting the same tool at different speeds, the surface finish will vary between lots. Not only that, some of our tools have up to 60 critical characteristics. With multiple people, multiple shift, the variation in production could be a nightmare,” Mr. Theile says.

One tool the customer didn’t want his cutters made on the previous CNC grinders. Taurus produced the tool on the MX7. The customer was impressed with the tool finish and was able to eliminate a tool coating operation. The tool cuts powdered metal parts.

“Now, all 16 ANCAs run off our server; none run locally. Engineering approves the program and machine setup so that each time a job is run, it is identical. All the notes are saved in the program. This is an extremely important point for us. No paper. It was very difficult to produce consistently with a variety of notes and changes.

Goal: Any Machine Can Produce Any Tool

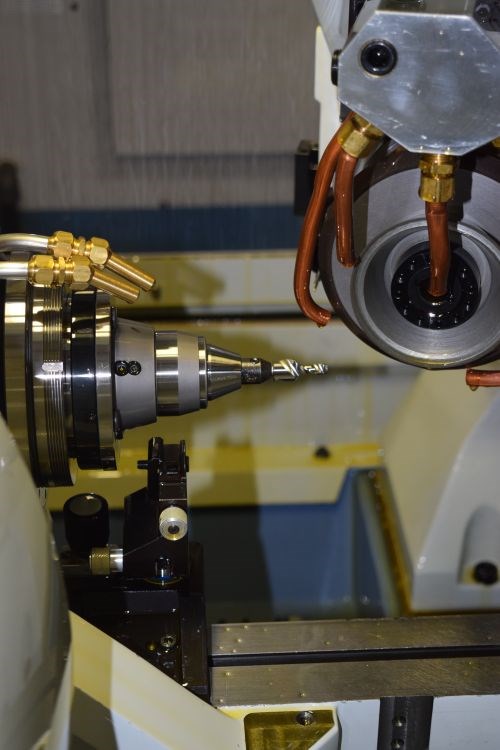

Taurus today is running four Fast Grinds and 12 MX7s, eight of those with the new ANCA LinX cylindrical linear motors in the X and Y axes and glass scales for high precision positioning, which according to Taurus improve reliability and contribute to improved tool surface finish. The MX7’s at Taurus have 10,000-rpm spindles.

A versatile CNC tool grinder designed for production grinding, the MX7 is built for high output, high precision manufacturing. The 38-kW (51-hp) permanent magnet spindle provides high torque at lower rpms, which is ideal for carbide grinding and a wide range of other applications. The MX7 Linear includes features that enable it to handle varied batch sizes with minimum setup time and tools to about 25 mm in diameter. For production, automated loading supports unattended grinding.

“The MX7 had the most versatility for us, helping us achieve what we wanted to achieve in producing quality tools for a wide range of users. We invested in available ANCA features to move away from the old habits. The ANCAs are newer, granted, but they are also faster with chilled, filtered coolant. Each machine has its own stand-alone EBBCO system. We have no ambient heat in the building so it is easier to hold tolerances,” Mr. Kantak says.

The ANCA grinding wheel changer increases machine productivity and flexibility. Within a 15-second wheel change time, an MX7 Linear with six HSK wheel packs can put the correct wheel on a wide range of tool designs.

The LinX linear motor’s even force over entire stroke provides consistent motion performance, and because of its direct drive, the motor can track motion commands more accurately and repetitively, resulting in better surface finish. The LinX Linear Motor also reduces cycle time due to its higher acceleration and faster traverse speed.

The MX7 Linear at Taurus Tool uses the same coolant system and chiller as the MX7 ballscrew machines. No special modifications are needed to the coolant system or the chiller unit to accommodate the MX7 Linear machine. “We have had no thermal concerns with the MX7 Linear. And the polymer concrete base on ANCA machines contributes significantly to the thermal stability of the machine.” Mr. Theile said.

Rigidity of the machine allows finer cuts. Most of the HSS tools at Taurus are roughed out on a lathe which imparts the profile of the tool, so the ANCAs can grind to very fine tolerances in short cycles.

Goal: Reduce Cycle Times, Improve Turnaround Times

Mr. Kantak says, “The versatility of the ANCAs also allows us to look at new tools we could not be competitive on previously because our cycle times were so long and our process was so detailed. Now we are competitive. On our largest running job we cut cycle time 40 percent – and that was a job on which we constantly tried hard to pare down the time.”

On a range of half-inch steel end mills, Taurus is about 30 percent faster, thanks to the six-wheel changer and quick setup. “We run about 5,000 per month but the lot size is about 150 so we have frequent changeover, and many setups. High pressure coolant, temperature controlled, a -up steady so we can move quickly in and out of operations, and machine rigidity help a great deal.

“Now we also have the ability to reduce the time gaps between operations so the wheels are approaching the part from only a couple of thousandths of an inch, rather than hundredths of thousandths, thus reducing cycle time significantly. Plus, the axis positioning is much faster with the MX7 – we used to waste minutes per parts with positioning.”

Setup times are low and getting lower. “It is about 50 percent better now and will probably get better because we are still learning the capability of the machines. It is constantly evolving, and we believe it is only going to get better. We are still nerds, toolmakers who are very interested in what we are doing. So we will learn all the features of the machines as we introduce new tool types,” Mr. Theile says.

Goal: Capture Tool Makers’ Experience, Eliminate Tribal Knowledge

Mr. Theile observes, “We had a crew of older toolmakers who are skilled in the art of toolmaking, and also a crew of younger guys who were comfortable with the technology. We now use the ANCAs and the Cimulator and ToolRoom software to extract that tribal knowledge so we capture it for the long term. The company is bigger than any employee.

“Continuous improvement of our process is our overall goal, and the ANCAs are a tool to support that, particularly with the notes for setups which we can attach to the tool manufacturing program. When you open a program, the notes pop up first, so that any improvements possible from the last time the job ran, can be implemented. Something so simple is so powerful for us,” Mr. Theile says.

Goal: Programming Made Easy

Menu-driven programming developed by ANCA for CNC toolmaking makes it easy to grind the tools designed in Cimulator. Programming is easy to pick up. ANCA’s ToolRoom software suite applies to a wide range of tool types and applications with an easy-to-use interface to input tool geometry parameters. ToolRoom ensures that the MX Linear machines will efficiently handle any regrinding or manufacture challenge, according to Mr. Theile.

The machine operator is able to easily and quickly set up or modify tool programs, depending upon the required tool type. For more proficient users, advanced software pages enable complex tool designs and operations. ToolRoom supports the grinding of drills, end mills, profile tools, burrs, routers and many other special applications.

Start Afresh

Mr. Theile observes, “The biggest battle was to get our people to forget the old way and start afresh. Once they start to see improvements in their programs, they get excited to make more improvements. So they buy-in.

“We felt that ANCA was going in the direction we wanted to go in terms of pushing the envelope in technology and support. Their support for a small business like ours has been very helpful, particularly in terms of applications. Plus, the support is local through two service engineers within a couple hours. They made a commitment and delivered,” Mr. Theile says.

“So the fire actually was a blessing for us since we were already working toward a new way of engineering and processing our tools. And it got a big push the day of the fire with ANCA asking us what we needed – get coffee, find machine time elsewhere, anything. They did a great job getting us the machines as soon as they could. After that, we got an ANCA every few weeks. And ANCA provided consistent support.

“There are not three guys more pleased with what their shop represents. As we move toward the 5S model in shop organization, we want to get our customers into our shop to see how we do our work, the capability of the shop, and enthusiasm of the employees.”

Read Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)